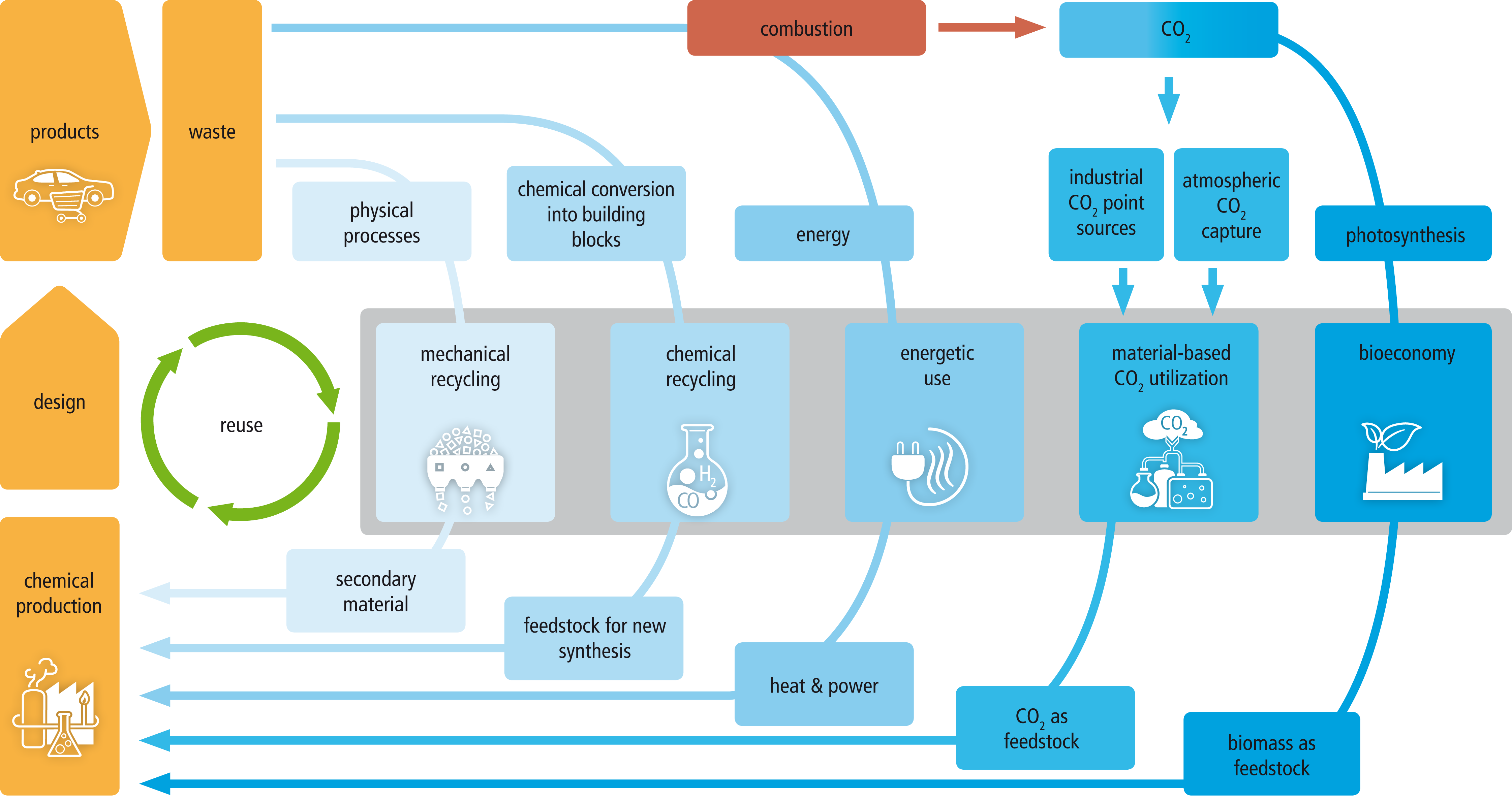

Anthropogenic Carbon Cycle

The Subtopic Anthropogenic Carbon Cycle tackles the challenge of a future carbon-neutral society, which needs

- renewable energy sources,

- carbon-based materials recycling technologies, and

- integrated process chains

combining both of the aforementioned technologies.

Possible cycles of carbon in the circular economy

In a future independent of fossil hydrocarbons, carbon will be available from

- biomass,

- from anthropogenic wastes and residue streams, and from

- unavoidable concentrated CO2-streams.

Thus, the feedstock basis of chemical industry and transportation fuels will change dramatically. The manufacturing of chemical products always requires carbon feedstocks.

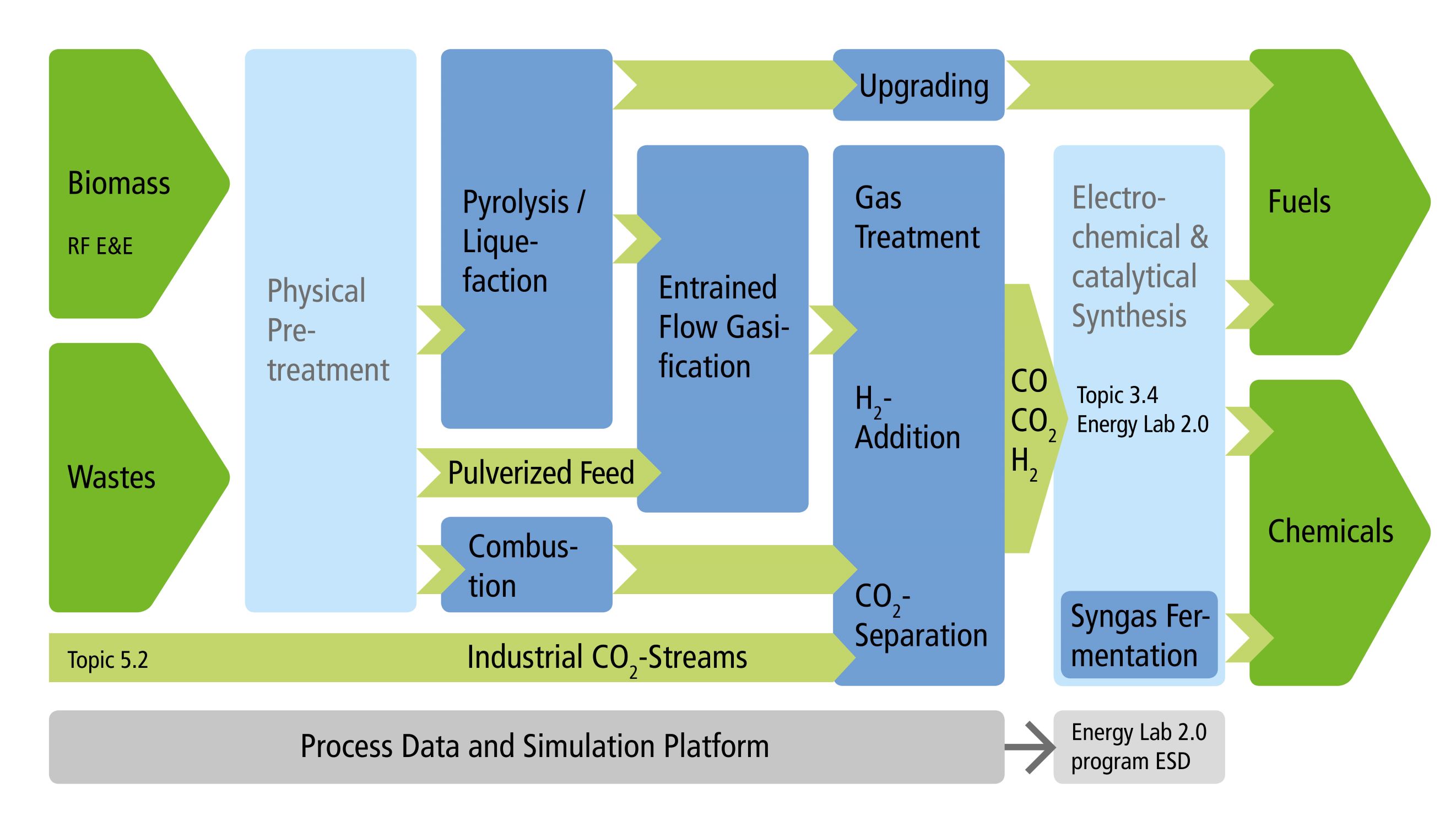

Feedstocks, material flows, processes and digitization of the Anthropogenic Carbon Cycle

Key-enabling technologies of a circular carbon economy (Anthropogenic Carbon Cycle)

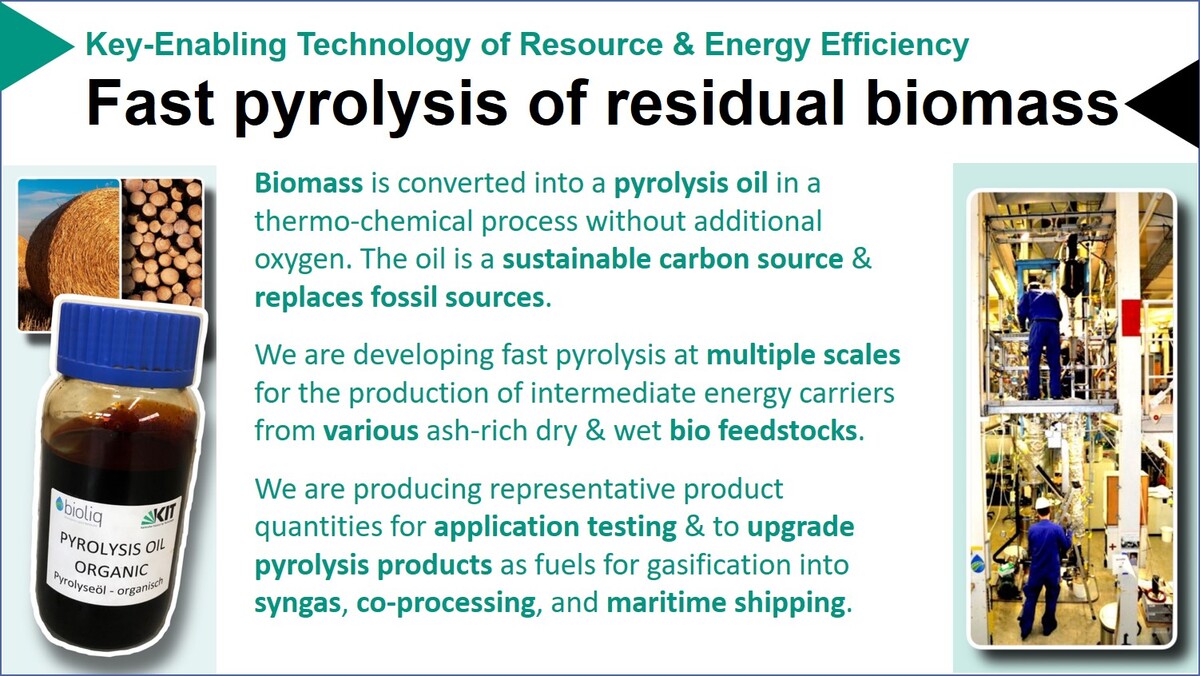

- Pyrolysis

- Fast pyrolysis of (residual) biomass

- Intermediate pyrolysis of plastic waste

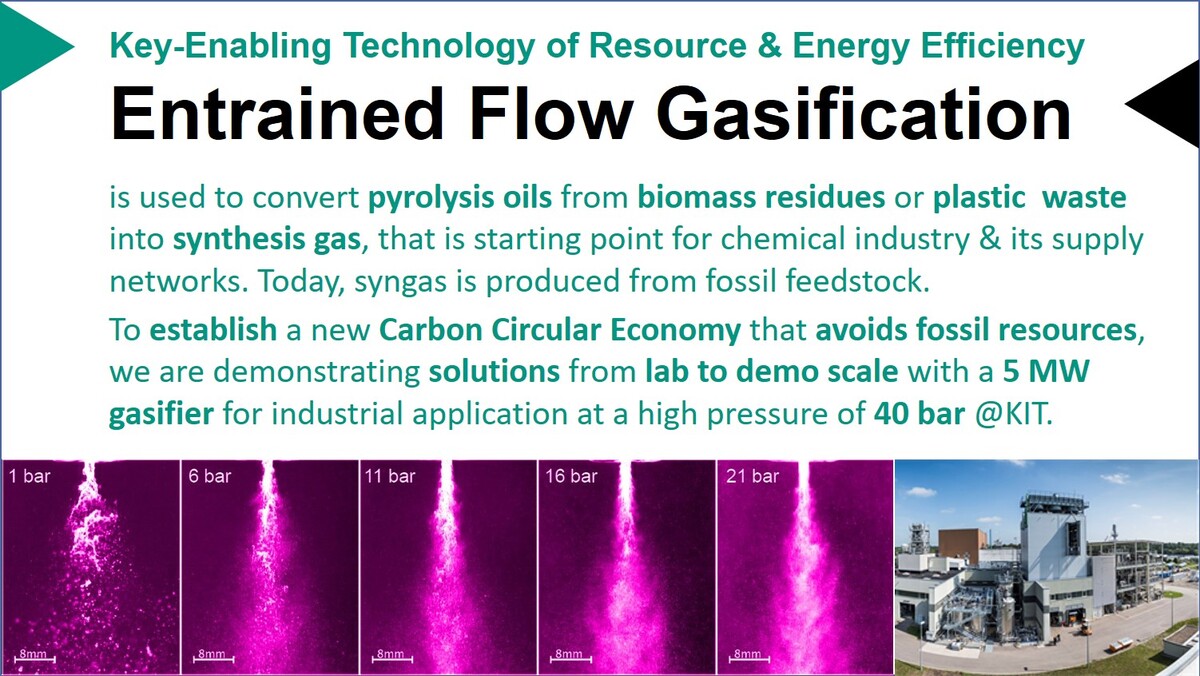

- Entrained flow gasification

- Upgrading

- Hot gas cleaning

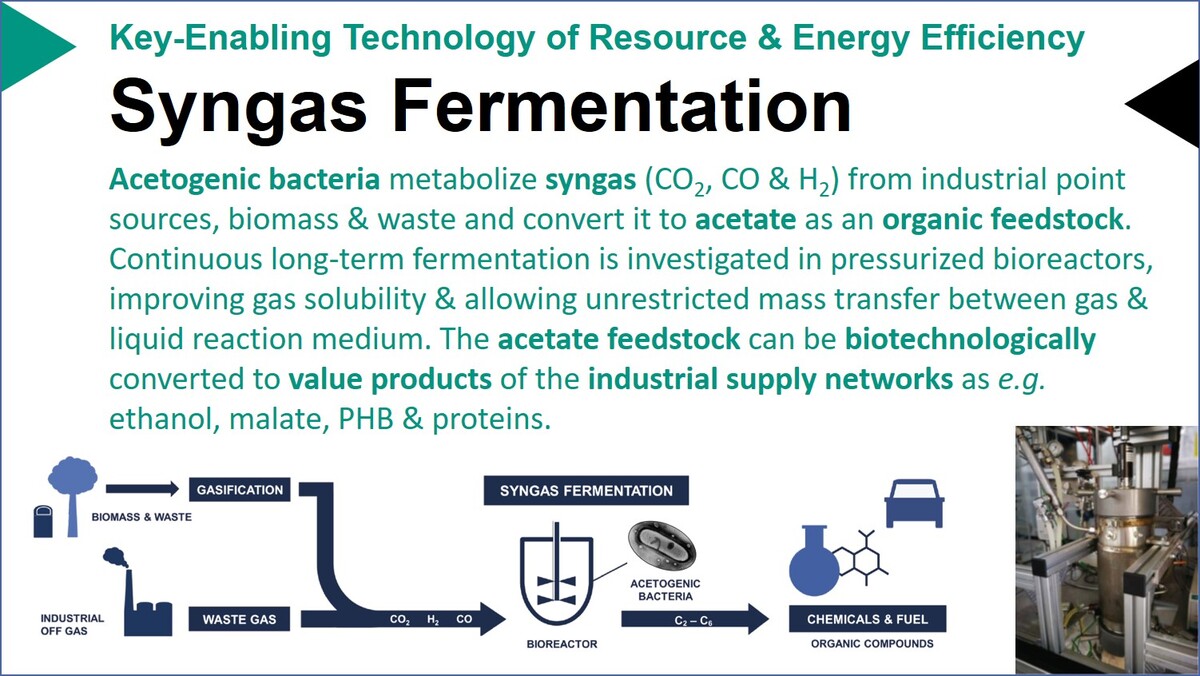

- Syngas fermentation

- Structure-property-process relations of materials

- Algae value chain

In the long-term, carbon-based compounds will be needed as energy carriers with high energy density and storability. In order to meet the targets of the Climate Protection Plan of the German Government, additional short-term measures need to be implemented specifically for the transportation sector. Advanced hydrocarbon fuels and oxygenates will have to play an important role in this scenario. The market introduction of these fuels can be based on the existing logistics infrastructure, which makes them especially important for the transition period. Their use will be an important long-term option for applications in which high energy density fuels are of particular importance.

Plastic waste recycling has to be a major pillar of the carbon cycle concept. The updated European Union regulatory framework forming the basis for national legislation sets the CE targets to be incorporated into the climate objectives: the 2008 Waste Framework Directive in which recovery operations/ recycling were made the guiding principle demands 65 weight-% recycling of municipal solid waste by 2030. A dramatic change in plastics recycling is required by the first EU plastics strategy (2018): 55 % of plastic waste will have to be recycled in 2030. This is equivalent to a surplus recycling capacity of approx. 11 million t/a in the EU.

In particular, recycling by producing chemicals (chemical recycling, waste-to-chemicals) has to be supported by new technologies, as real waste is a complex mixture of often chemically bound organic and inorganic materials that cannot be fully separated by physical processes.

Selected Projects

|

|

Publications

-

Ebel, C. F. W.; Richter, L.; Minden, S.; Meurer, T.; Kaster, A.-K.; Wolf, M.; Sauer, J.

Development and application of a predictive fermentation model for continuous and pressurized fermentation using Clostridium ljungdahlii

2026. Chemical Engineering Journal, 527, 171744. doi:10.1016/j.cej.2025.171744 -

Monning, M.; Asadli, A.; Bajohr, S.; Wolf, M.; Kolb, T.

Determination of reaction kinetics in three phase CO 2 methanation

2026. Reaction Chemistry & Engineering, Art.-Nr.: d5re00337g. doi:10.1039/D5RE00337G -

Wen, Y.; Li, W.; Sharapa, D. I.; Zevaco, T. A.; Schild, D.; Studt, F.; Raffelt, K.; Dahmen, N.

Engineering Ni(0)/Ni(II) interfaces in LDH-Derived Ni–Al catalysts for mild lignin depolymerization

2026. Bioresource Technology, 442, 133697. doi:10.1016/j.biortech.2025.133697 -

Zeller, M.; Wattenberg, L.; Shrestha, P.; Hannemann, A.; Erdenepurev, A.-E.; Netsch, N.; Bergfeldt, B.; Tavakkol, S.; Stapf, D.

Characteristics of Polyurethane Pyrolysis - Experimental Investigations and Product Analyses for the Assessment of Chemical Recycling Potentials

2026. Journal of applied polymer science, 143 (7), Art.-Nr.: e70032. doi:10.1002/app.70032 -

Seiler, M.; Guardi, G.; Wagner, S.; Pundt, A.

Applicability range of potential step chronoamperometry for determining reliable diffusion coefficients of hydrogen and lithium in host materials

2026. Electrochimica Acta, 546, Art.-Nr. 147790. doi:10.1016/j.electacta.2025.147790 -

Hazenberg, T.; Braig, D.; Fedoryk, M. A.; Mich, J.; Hagen, F. P.; Harth, S. R.; Stelzner, B.; Scholtissek, A.; Trimis, D.; Hasse, C.

Analyzing iron dust bunsen flames using numerical simulations

2026. Fuel, 403, 136094. doi:10.1016/j.fuel.2025.136094 -

Seitz, M.; Kannengießer, M. P.; Stelzner, B.; Hagen, F. P.; Braun, L.; Kaltenbach, J.; Märkle, K.; Peterlechner, M.; Spielmann, J.; Doronkin, D. E.; Deutschmann, M. P.; Grunwaldt, J.-D.; Eggeler, Y. M.; Kramm, U. I.; Nirschl, H.; Trimis, D.

Reduction of micron-sized iron oxide particles with high initial porosity in a fluidized bed reactor using hydrogen: Morphology and phase analysis

2026. Fuel, 405, Art.-Nr.: 136422. doi:10.1016/j.fuel.2025.136422 -

Dammann, M.; Hüsing, F.; Santo, U.; Böning, D.; Mancini, M.; Kolb, T.

Characterisation of beech wood pyrolysis oil: Chemical and physical properties and decomposition kinetics

2026. Fuel, 404, 134897. doi:10.1016/j.fuel.2025.134897

-

Netsch, N.; Tauber, A.; Keskin, O.; Bergfeldt, B.; Wehner, H.; Eidam, D.; Tavakkol, S.; Stapf, D.

Chemical Recycling of Mixed Thermoplastics via Pyrolysis: A Comparative Study of Feedstock Influence and Reactor Impact

2025. Journal of analytical and applied pyrolysis, 107575. doi:10.1016/j.jaap.2025.107575 -

Bytyqi, H.; Mujdeci, G. N.; Ekici, E.; Ozturk, A. B.; Celik Madenli, E.; Kumar, G.

Review of lignocellulosic bio-chemical production: Current challenges, advances, and future perspectives

2025. Energy Nexus, 20, 100543. doi:10.1016/j.nexus.2025.100543 -

Zhang, X.; Wang, W.; Yan, J.; Lu, Y.; Ghorbannezhad, P.; Li, Z.; Fu, P.

Controlled alkylation of lignin-based aromatics over N-ZSM-5 catalysts for the production of C8-C15 aromatics in jet fuels

2025. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 47 (1), 10035–10046. doi:10.1080/15567036.2025.2496295 -

Parku, G. K.; Collard, F.-X.; Görgens, J. F.

Pyrolysis of Waste Polypropylene Plastics for Energy Recovery: Optimization of Product Yield and Quality on a Commissioned Pilot-Scale Setup

2025. Energy & Fuels, 39 (13), 6310–6318. doi:10.1021/acs.energyfuels.4c05902 -

Yu, X.; Zhao, Y.; Zhang, Z.; Zhang, F.; Liu, L.

Effects of Hydrogen Blending Ratio and Fuel Axial Staged Ratio on Methane–Hydrogen Fuel Mixture Combustion Characteristics and NO

2025. Energy Technology, 13 (11). doi:10.1002/ente.202500122 -

Aleksandrov, K.; Gehrmann, H.-J.; Wiebe, J.; Stapf, D.

Ammonia—A Fuel of the Future? Economies of Production and Control of NO

2025. Energies, 18 (22), Art.-Nr.: 5948. doi:10.3390/en18225948 -

Shamooni, A.; Cheng, R.; Zirwes, T.; Stein, O. T.; Kronenburg, A.

Super-resolution reconstruction of scalar fields from the pyrolysis of pulverised biomass using deep learning

2025. Proceedings of the Combustion Institute, 41, 105982. doi:10.1016/j.proci.2025.105982 -

Walker, S.; Kolb, T.

Pressurized Gasification of Beech Wood Char in Steam and Steam–CO 2 Mixtures: Kinetics Considering Steam–CO

2025. Energy & Fuels, 39 (49), 23291–23303. doi:10.1021/acs.energyfuels.5c04287 -

Lagemann, E.; Roeb, J.; Brunton, S. L.; Lagemann, C.

A deep learning approach to wall-shear stress quantification: from numerical training to zero-shot experimental application

2025. Journal of Fluid Mechanics, 1014, Art.-Nr. A1. doi:10.1017/jfm.2025.10150 -

Hennig, M.; Dreising, T. M.; Reeves, A.; Oehlcke, T.; Tavakkol, S.; Volk, R.; Schultmann, F.; Stapf, D.

Entrained-Flow Gasification for the Utilization of Pyrolysis Oil from Mixed Plastic Waste

2025. ACS sustainable chemistry & engineering. doi:10.1021/acssuschemeng.5c03932 -

Bulsink, P.; Nguyen, L.; Gupta, M.; Collard, F.-X.; Funke, A.; Jeaidi, J.; Bronson, B.

Interlaboratory Study of Sample Homogeneity Impact on CHNS, Water, and ICP Analysis of Biomass Liquefaction Oils

2025. Energy & Fuels, 39 (29), 14223–14236. doi:10.1021/acs.energyfuels.5c01309 -

Netsch, N.; Weigel, L.; Schmedding, T.; Zeller, M.; Bergfeldt, B.; Straczewski, G.; Tavakkol, S.; Stapf, D.

Chemical characterization of mixed plastic pyrolysis oils relevant for cracker reintegration by advanced two-dimensional gas chromatography

2025. Fuel Processing Technology, 280, 108359. doi:10.1016/j.fuproc.2025.108359 -

Horn, H.; Kolb, T.; Trimis, D.; Rauch, R.; Scheiff, F.; Stein, O. T.; Wolf, M.

Engler-Bunte-Institut des Karlsruher Instituts für Technologie (KIT) im Jahr 2024, Teil 3

2025. GWF, Wasser - Abwasser, 166 (6), 71–80 -

Sarasidis, V. C.; Dutzi, J.; Petsi, P. N.; Plakas, K. V.; Boukis, N.; Sauer, J.

Decontamination of high salinity supercritical water gasification wastewater by an integrated electrocoagulation / electrochemical oxidation process

2025. Journal of Environmental Chemical Engineering, 13 (5), 118491. doi:10.1016/j.jece.2025.118491 -

Shamooni, A.; Cheng, R.; Zirwes, T.; Tofighian, H.; Stein, O. T.; Kronenburg, A.

Super-resolution of turbulent velocity fields in two-way coupled particle-laden flows

2025. Physics of Fluids, 37 (9), Art.-Nr.: 093383. doi:10.1063/5.0288515 -

Bauer, M.; Stelzner, B.; Habisreuther, P.; Schneider, M.; Weis, C.; Trimis, D.

Experimental investigation of turbulent premixed H

2025. Proceedings of the Combustion Institute, 41, 105866. doi:10.1016/j.proci.2025.105866 -

Gyawali, P.; Shrestha, B.; Phanomsophon, T.; Posom, J.; Pornchaloempong, P.; Sirisomboon, P.; Shrestha, B. P.; Funke, A.

Predicting biomass global warming potential with FT-NIR spectroscopy

2025. Scientific Reports, 15 (1), Art.-Nr.: 33725. doi:10.1038/s41598-025-10584-z -

Arlt, S.; Köffler, T.; Wustinger, I.; Aichernig, C.; Rauch, R.; Hofbauer, H.; Weber, G.

Opportunities and Challenges in Reducing the Complexity of the Fischer–Tropsch Gas Loop of Smaller-Scale Facilities for the Production of Renewable Hydrocarbons

2025. Energies, 18 (20), Article no: 5479. doi:10.3390/en18205479 -

Naiara, T.; Mariana, C. F.; Thomas, Z.; Klaus, R.; Ricardo, S.

NiFe Catalysts Supported on Nb

2025. Topics in Catalysis, 68 (20), 2521–2535. doi:10.1007/s11244-025-02177-x -

Puri, R.; Kretzler, D.; Bock-Seefeld, B.; Stelzner, B.; Brachhold, N.; Hubálková, J.; Trimis, D.; Aneziris, C.; Stein, O. T.; Zirwes, T.

Influence of dispersion length on volume-averaged simulations of ammonia/air combustion in porous media burners

2025. Proceedings of the Combustion Institute, 41, 105856. doi:10.1016/j.proci.2025.105856 -

Kretzler, D.; Puri, R.; Stelzner, B.; Zirwes, T.; Hagen, F. P.; Stein, O. T.; Trimis, D.

Experimental and numerical investigation of non-premixed ammonia flames stabilized on a heated slot burner

2025. Proceedings of the Combustion Institute, 41, 105854. doi:10.1016/j.proci.2025.105854 -

Saggese, C.; Whitesides, R.; Wagnon, S. W.; Chatterjee, T.; Hagen, F. P.; Vlavakis, P.; Schraud, N.; Trimis, D.

Soot formation and precursor chemistry in Counterflow flames of aviation fuel surrogates

2025. Proceedings of the Combustion Institute, 41, Art.-Nr.: 105816. doi:10.1016/j.proci.2025.105816 -

Stallkamp, C.; Oehlcke, T.; Volk, R.; Hennig, M.; Schultmann, F.

How do political steering instruments influence the integration of chemical recycling into plastic recycling networks? A case study for Germany

2025. Journal of Industrial Ecology. doi:10.1111/jiec.70080 -

Hergt, M.; Hammer, B.; Sack, M.; Mayer, L. W.; Nielebock, S.; Hiller, M.

Modelling of SiC and GaN transistors based on pulsed S-parameter measurements

2025. Power Electronic Devices and Components, 12, 100108. doi:10.1016/j.pedc.2025.100108 -

Margellou, A. G.; Langschwager, F.; Pappa, C. P.; Araujo, A. C. C.; Funke, A.; Triantafyllidis, K. S.

Solvolysis and Mild Hydrogenolysis of Lignin Pyrolysis Bio-Oils for Bunker Fuel Blends

2025. Energies, 18 (14), Art.-Nr.: 3683. doi:10.3390/en18143683 -

Becka, R.; Bajohr, S.; Kolb, T.

Review on CO₂ Activation via Catalytic Reverse Water‐Gas Shift Reaction

2025. Chemie Ingenieur Technik, 97 (8-9), 860–881. doi:10.1002/cite.70013 -

Zeller, M.; Tavakkol, S.; Stapf, D.

Experimental and Analytical Tools for the Chemical Recycling of Engineering Plastics – A Multi‐Scale Pyrolysis Study on Polydicyclopentadiene

2025. Macromolecular Rapid Communications, 46 (23), 2500161. doi:10.1002/marc.202500161 -

Araujo, A. C. C. de; Funke, A.; Margellou, A.; Triantafyllidis, K.; Dahmen, N.

Pilot scale fast pyrolysis of lignin in a twin-screw reactor

2025. Biomass and Bioenergy, 200, 108041. doi:10.1016/j.biombioe.2025.108041 -

Li, J.; Mao, M.; Zhang, Z.; Zhang, F.; He, F.; Shi, J.; Liu, Y.; Wang, Y.; Li, C.; Gao, H.

Numerical study of flame tilt instability during filtration combustion with reverse flow and extra lean methane/air mixture through a multi-scale model

2025. Applied Thermal Engineering, 276, 126882. doi:10.1016/j.applthermaleng.2025.126882 -

Wild, J.; Wagner, S.; Pundt, A.; Guth, S.

Influence of Electrolytic Hydrogen Charging and Effusion Aging on the Rotating Bending Fatigue Resistance of SAE 52100 Steel

2025. Corrosion and Materials Degradation, 6 (3), Article no: 30. doi:10.3390/cmd6030030 -

Schaefer, W.; Fleck, S.; Haas, M.; Jakobs, T.

Optical Measurement Method for Monitoring High-Mass-Concentration Slurry Sprays: An Experimental Study

2025. Photonics, (12), 673. doi:10.3390/photonics12070673 -

Vogt, J.; Renno, A. D.; Fuchs, M.; Kurtz, T.; Netsch, N.; Richter, F.; Straczewski, G.; Bergfeldt, B.; Madriz-Diaz, Y. C.; Ribeiro, A. de L.; Ebert, D.; Tavakkol, S.; Raatz, S.; Stapf, D.

Chemical recycling of refrigerator plastic waste by pyrolysis: Yields, product composition, and potential applications

2025. Fuel, 400, Art.-Nr.: 135776. doi:10.1016/j.fuel.2025.135776 -

Dutzi, J.; Vadarlis, A. A.; Boukis, N.; Sauer, J.

Development and Parametrization of a Novel Reactor Concept for the Supercritical Water Gasification Process

2025. Industrial and Engineering Chemistry Research, 64 (19), 9500–9517. doi:10.1021/acs.iecr.4c04267 -

Sauer, J.; Wachsen, O.

Zirkularität – Die Herausforderung des Chemieingenieurwesens

2025. Chemie Ingenieur Technik, 97 (6), 588–598. doi:10.1002/cite.202500009 -

Held, M.; Rieck, A.; Bajohr, S.; Kolb, T.

Hydrogenation of dibenzyl toluene - A competing side reaction in three phase methanation

2025. International Journal of Hydrogen Energy, 132, 166 – 173. doi:10.1016/j.ijhydene.2025.04.171 -

Sack, M.; Herzog, D.; Müller, G.

GaN-HEMT in Gate-Boosted Operation as Closing Switch in a Blumlein Generator With Adjustable Pulselength

2025. IEEE Transactions on Plasma Science, 53 (10), 2606–2611. doi:10.1109/TPS.2025.3560580 -

Arlt, J.; Meyer, T.; Roscher, M.; Brede, T.; Borchers, C.; Schwarz, T. M.; Stender, P.; Pundt, A.; Volkert, C. A.

Non-Equilibrium Microstructures in Iron-Carbon Thin Films: Co-Evolution of Carbon Clusters and Ferrite Nanograins

2025. Acta Materialia, 293, Art.-Nr.: 121124. doi:10.1016/j.actamat.2025.121124 -

Ekici, E.; Joka Yildiz, M.; Kalinowska, M.; Wang, J.; Yildiz, G.

Co-pyrolysis of waste wind turbine blades in a molten polyolefin medium

2025. Journal of Analytical and Applied Pyrolysis, 190, 107143. doi:10.1016/j.jaap.2025.107143 -

Hagen, F. P.; Müller, J. H.; Störmer, H.; Stelzner, B.; Eggeler, Y. M.; Trimis, D.

On nanoparticles in iron dust flames of Bunsen-type: Evolution of size distribution and hetero-coagulation with micron-sized particles

2025. Fuel, 398, Art.:135598. doi:10.1016/j.fuel.2025.135598 -

Haas, M.; Fleck, S.; Jakobs, T.; Kolb, T.

Liquid fuel evaporation under entrained flow gasification conditions – Insights for burner development

2025. Thermal Science and Engineering Progress, 59, Art.-Nr.: 103342. doi:10.1016/j.tsep.2025.103342 -

Bala, E.; Hornung, U.; Dahmen, N.

Hydrothermal Liquefaction (HTL) of Lignin: The Adsorption Separation of Catechol Guaiacol and Phenol

2025. Energies, 18 (9), 2181. doi:10.3390/en18092181 -

Wen, Y.; Zormpa, F.; Sharapa, D. I.; Studt, F.; Raffelt, K.; Dahmen, N.

Exploring the hydrodeoxygenation of lignin β-O-4 dimer model compound and bio-oil by DFT and experimental studies

2025. Molecular Catalysis, 580, 115134. doi:10.1016/j.mcat.2025.115134 -

del Barrio Montañés, A.; Senaj, V.; Kramer, T.; Müller, G.; Sack, M.

Compact Design and Impact Ionization: Utilizing Small-Sized Thyristors in a 4-Stage Marx Generator

2025. Applied Sciences, 15 (6), Article no: 3289. doi:10.3390/app15063289 -

Vadarlis, A. A.; Neukum, D.; Dutzi, J.; Lemonidou, A. A.; Boukis, N.; Sauer, J.

Supercritical water gasification and subsequent steam reforming of the product gas under elevated temperature and pressure

2025. International Journal of Hydrogen Energy, 111, 567 – 580. doi:10.1016/j.ijhydene.2025.02.197 -

Rojas, M.; Fonseca, F. G.; Hornung, U.; Funke, A.; Dahmen, N.

Synthetic Lignin Oligomers: Analytical Techniques, Challenges, and Opportunities

2025. ChemSusChem, 18 (10). doi:10.1002/cssc.202402334 -

Vorotiahin, I.; Hergt, M.; Sack, M.; Hiller, M.; Müller, G.

Streamlined Behavioral Modeling of GaN HEMTs for Pulsed-Power Applications

2025. IEEE Transactions on Plasma Science, 53 (10), 2612–2617. doi:10.1109/TPS.2025.3542461 -

Wörner, M.; Hornung, U.; Karagöz, S.; Zevaco, T.; Dahmen, N.

Focus on hydrochars produced from hydrothermal liquefaction of beech wood, soda lignin and black liquor

2025. European Journal of Wood and Wood Products, 83 (2), 61. doi:10.1007/s00107-025-02214-2 -

Nguyen, B.-D.; Scholtissek, A.; Li, T.; Ning, D.; Stein, O. T.; Dreizler, A.; Hasse, C.

Nanoparticle formation in the boundary layer of burning iron microparticles: Modeling and simulation

2025. Chemical Engineering Journal, 507, 160039. doi:10.1016/j.cej.2025.160039 -

Zeller, M.; Merz, D.; Weigel, L.; Tavakkol, S.; Stapf, D.

TG-FTIR Investigations of the Pyrolysis of Polyurethanes: Quantitative Carbon Dioxide Tracing, Decomposition Mechanisms, Products and Mass Balances for Advanced Recycling

2025. Journal of Analytical and Applied Pyrolysis, 188, 107048. doi:10.1016/j.jaap.2025.107048 -

Xing, X.; Cao, W.; Yan, J.; Zhang, Y.; Ghorbannezhad, P.; Li, Z.; Fu, P.

Conversion of Lignin to Cyclohexanol via Mild Catalytic Depolymerization Coupled with Hydrogenation

2025. Journal of Environmental Chemical Engineering, 13 (1), 115082. doi:10.1016/j.jece.2024.115082 -

Yousefi Seyf, J.; Nasrollahi, B.; Jalalinejad, A.

Development of the Wilson Functional Activity Coefficient Model Using High-Quality and Critically Evaluated Phase Equilibria Data

2025. Industrial & Engineering Chemistry Research, 64 (1), 888–900. doi:10.1021/acs.iecr.4c03712 -

Papachristou, I.; Nazarova, N.; Wüstner, R.; Lina, R.; Frey, W.; Silve, A.

Biphasic lipid extraction from microalgae after PEF-treatment reduces the energy demand of the downstream process

2025. Biotechnology for Biofuels and Bioproducts, 18 (1), Art.-Nr.: 12. doi:10.1186/s13068-025-02608-7 -

Rojas, M.; Manrique, R.; Hornung, U.; Funke, A.; Mullen, C. A.; Chejne, F.; Maya, J. C.

Advances and challenges on hydrothermal processes for biomass conversion: Feedstock flexibility, products, and modeling approaches

2025. Biomass and Bioenergy, 194, 107621. doi:10.1016/j.biombioe.2025.107621 -

Zhang, F.; Tavakkol, S.; Galeazzo, F. C. C.; Stapf, D.

Particle-resolved simulation of the pyrolysis process of a single plastic particle

2025. Heat and Mass Transfer, 61 (1), 12. doi:10.1007/s00231-024-03524-6 -

Naim, W.; Treu, P.; Dohrn, M.; Saraçi, E.; Grunwaldt, J.-D.; Fendt, S.; Spliethoff, H.

Structure-Reactivity- and Modelling-Relationships during Thermal Annealing in Biomass Entrained-Flow Gasification: The Effect of Temperature and Residence Time

2025. Fuel, 383, Art.-Nr.: 133848. doi:10.1016/j.fuel.2024.133848 -

Korneychuk, S.; Wagner, S.; Rohleder, D.; Vana, P.; Pundt, A.

Local Hydrogen Concentration and Distribution in Pd Nanoparticles: An In Situ STEM‐EELS Approach

2025. Small, Art.-Nr.: 2407092. doi:10.1002/smll.202407092 -

Korneychuk, S.; Grosselindemann, C.; Menzler, N. H.; Weber, A.; Pundt, A.

In-situ TEM reduction of a solid oxide cell with NiO/YSZ fuel electrode

2025. Journal of Power Sources, 625, 235626. doi:10.1016/j.jpowsour.2024.235626 -

Walker, S.; Kolb, T.

Operation of a differential fixed bed reactor for investigations on micro-kinetics of heterogeneous gasification reactions

2025. Fuel, 381 (Part C), 133561. doi:10.1016/j.fuel.2024.133561 -

Dammann, M.; Santo, U.; Böning, D.; Knoch, H.; Eberhard, M.; Kolb, T.

Entrained flow gasification: Pilot-scale experimental, balancing and equilibrium data for model validation

2025. Fuel, 382, 132809. doi:10.1016/j.fuel.2024.132809 -

Silva, W. R.; Santos, T. M.; Carregosa, J. C.; Schmitt, C. C.; Raffelt, K.; Dahmen, N.; Wisniewski, A., Jr

Correction to: Bio-oil as a source of renewable chemicals: the chemistry of pyrolytic lignin

2025. Biomass Conversion and Biorefinery, 15 (4), 5419–5420. doi:10.1007/s13399-024-05756-2 -

Sen, U.; Fonseca, F. G.; Chi, Y.; Pereira, H.; Funke, A.

Fast pyrolysis of the waste lignocellulosic phloem fraction of Quercus cerris bark in a twin-screw reactor

2025. Biomass Conversion and Biorefinery, 15 (7), 10251–10260. doi:10.1007/s13399-024-05921-7 -

Kussin, P.; Stegmaier, T.; Müller, C.; Mörs, F.; Graf, F.

Ein neues Konzept zur CO 2 ‐Bereitstellung aus Luft als Gaswäsche mit ionischen Flüssigkeiten

2025. Chemie Ingenieur Technik, 97 (1-2), 32–42. doi:10.1002/cite.202300140 -

Silva, W. R.; Santos, T. M.; Carregosa, J. C.; Schmitt, C. C.; Raffelt, K.; Dahmen, N.; Wisniewski, A., Jr

Bio-oil as a source of renewable chemicals: the chemistry of pyrolytic lignin

2025. Biomass Conversion and Biorefinery, 15 (4), 5401–5418. doi:10.1007/s13399-024-05622-1 -

Staudt, C.; Hofsäß, C.; Lewinski, B. von; Mörs, F.; Prabhakaran, P.; Bajohr, S.; Graf, F.; Kolb, T.

Process Engineering Analysis of Transport Options for Green Hydrogen and Green Hydrogen Derivatives

2025. Energy Technology, 13 (2), Art.-Nr.: 2301526. doi:10.1002/ente.202301526

-

Gyawali, P.; Shrestha, B.; Posom, J.; Pornchaloempong, P.; Sirisomboon, P.; Shrestha, B. P.; Funke, A.

Identification and Removal of Negative Biomass Samples via Scatter Plot Analysis to Improve GWP Predictive Modeling

2025. S. Devahastin, J. Posom & T. Treeamnuk (Eds.), E3S Web of Conferences. Ed.: S. Devahastin, J. Posom, T. Treeamnuk, Art.-Nr.: 04021, EDP Open. doi:10.1051/e3sconf/202566104021

-

Niksirat, M.; Aeenjan, F.; Pierantozzi, M.; Jalalinejad, A.; Khosharay, S.

Modeling the viscosity of (water + methanol), (water + ethanol), (water + 1-propanol) and (water + 2-propanol) mixture up to the high pressures

2024. Brazilian Journal of Chemical Engineering, 42 (4), 1673–1692. doi:10.1007/s43153-024-00515-2 -

Ekici, E.; Yildiz, G.; Yildiz, M. J.; Kalinowska, M.; Şeker, E.; Wang, J.

Continuous flow pyrolysis of virgin and waste polyolefins: a comparative study, process optimization and product characterization

2024. Frontiers of Chemical Science and Engineering, 18 (6), Art.-Nr.: 70. doi:10.1007/s11705-024-2429-x -

Salas, M. R.; Fonseca, F. G.; de Araujo, A. C. C.; García-Perez, M.; Funke, A.

Liquid–Liquid Equilibrium Prediction in Fast Pyrolysis Bio-Oil Systems: A Framework for Incorporating Bio-Oil Complexity

2024. Energy & Fuels, 38 (19), 18769–18780. doi:10.1021/acs.energyfuels.4c03387 -

Gehrmann, H.-J.; Taylor, P.; Aleksandrov, K.; Bergdolt, P.; Bologa, A.; Blye, D.; Dalal, P.; Gunasekar, P.; Herremanns, S.; Kapoor, D.; Michell, M.; Nuredin, V.; Schlipf, M.; Stapf, D.

Mineralization of fluoropolymers from combustion in a pilot plant under representative european municipal and hazardous waste combustor conditions

2024. Chemosphere, 365, 143403. doi:10.1016/j.chemosphere.2024.143403 -

Netsch, N.; Schröder, L.; Zeller, M.; Neugber, I.; Merz, D.; Klein, C. O.; Tavakkol, S.; Stapf, D.

Thermogravimetric study on thermal degradation kinetics and polymer interactions in mixed thermoplastics

2024. Journal of thermal analysis and calorimetry. doi:10.1007/s10973-024-13630-6 -

Vadarlis, A. A.; Lacerda de Oliveira Campos, B.; Lemonidou, A. A.; Boukis, N.; Sauer, J.

Supercritical Water Gasification of Ethanol as Biomass Model Compound in Tandem with Steam Reforming: Kinetic Modeling of the Reforming Step and Techno-Economic Analysis of the Integrated Concept

2024. Industrial and Engineering Chemistry Research, 63 (39), 16683–16700. doi:10.1021/acs.iecr.4c01486 -

Wen, X.; Shamooni, A.; Zirwes, T.; Stein, O. T.; Kronenburg, A.; Hasse, C.

Carrier-phase direct numerical simulation and flamelet modeling of NO

2024. Combustion and Flame, 269, 113722. doi:10.1016/j.combustflame.2024.113722 -

Gault, B.; Saksena, A.; Sauvage, X.; Bagot, P.; Aota, L. S.; Arlt, J.; Belkacemi, L. T.; Boll, T.; Chen, Y.-S.; Daly, L.; Djukic, M. B.; Douglas, J. O.; Duarte, M. J.; Felfer, P. J.; Forbes, R. G.; Fu, J.; Gardner, H. M.; Gemma, R.; Gerstl, S. S. A.; Gong, Y.; Hachet, G.; Jakob, S.; Jenkins, B. M.; Jones, M. E.; Khanchandani, H.; Kontis, P.; Krämer, M.; Kühbach, M.; Marceau, R. K. W.; Mayweg, D.; Moore, K. L.; Nallathambi, V.; Ott, B. C.; Poplawsky, J. D.; Prosa, T.; Pundt, A.; Saha, M.; Schwarz, T. M.; Shang, Y.; Shen, X.; Vrellou, M.; Yu, Y.; Zhao, Y.; Zhao, H.; Zou, B.

Towards Establishing Best Practice in the Analysis of Hydrogen and Deuterium by Atom Probe Tomography

2024. Microscopy and Microanalysis. doi:10.1093/mam/ozae081 -

Khajavi, S.; Schlabach, S.; Pundt, A.; Huot, J.

Oxidation and compositional modulation in single phase C14 Zr

2024. Journal of Alloys and Compounds Communications, 3, Art.-Nr.: 100026. doi:10.1016/j.jacomc.2024.100026 -

Jonynaite, K.; Stirke, A.; Gerken, H.; Frey, W.; Gusbeth, C.

Influence of growth medium on the species‐specific interactions between algae and bacteria

2024. Environmental Microbiology Reports, 16 (4), Article no: e13321. doi:10.1111/1758-2229.13321 -

Chowdhury, C.

Bayesian Optimization for Efficient Prediction of Gas Uptake in Nanoporous Materials

2024. ChemPhysChem, 25 (16), Art.-Nr.: e202300850. doi:10.1002/cphc.202300850 -

Shamooni, A.; Wen, X.; Debiagi, P.; Stagni, A.; Gärtner, J. W.; Zirwes, T.; Stein, O. T.; Hasse, C.; Kronenburg, A.

Carrier-phase direct numerical simulation and flamelet modeling of alkali metal emissions from pulverized biomass flames

2024. Proceedings of the Combustion Institute, 40 (1-4), 105309. doi:10.1016/j.proci.2024.105309 -

Freund, H.; Sauer, J.; Ehrhardt, K.

Die Fachsektion Chemische Reaktionstechnik von DECHEMA und VDI hat sich neu formiert

2024. Chemie Ingenieur Technik, 96 (6), 719. doi:10.1002/cite.202400059 -

Zimmerman, J.; Vrellou, M.; Wagner, S.; Pundt, A.; Kirchlechner, C.; Rabkin, E.

Drastic softening of Pd nanoparticles induced by hydrogen cycling

2024. Scripta Materialia, 253, Art.-Nr. 116304. doi:10.1016/j.scriptamat.2024.116304 -

Chen, Y.; Ji, M.; Zhang, F.; Li, J.; Pan, H.; Zhao, Y.; Zhang, Z.; Liu, L.

Investigation of Tribological Behavior and Lubrication Mechanisms of Zinc Oxide under Poly α‑olefin Lubrication Enhanced by the Electric Field

2024. Langmuir, 40 (13), 6741–6749. doi:10.1021/acs.langmuir.3c03458 -

Zirwes, T.; Zhang, F.; Kaiser, T. L.; Oberleithner, K.; Stein, O. T.; Bockhorn, H.; Kronenburg, A.

The role of thermodiffusion and dimensionality in the formation of cellular instabilities in hydrogen flames

2024. Proceedings of the Combustion Institute, 40 (1-4), Art.-Nr.: 105665. doi:10.1016/j.proci.2024.105665 -

Shrestha, B.; Posom, J.; Sirisomboon, P.; Shrestha, B. P.; Funke, A.

Effect of Combined Non-Wood and Wood Spectra of Biomass Chips on Rapid Prediction of Ultimate Analysis Parameters Using near Infrared Spectroscopy

2024. Energies, 17 (2), Art.-Nr.: 439. doi:10.3390/en17020439 -

Shrestha, B.; Posom, J.; Sirisomboon, P.; Shrestha, B. P.; Pornchaloempong, P.; Funke, A.

NIR Spectroscopy as an Alternative to Thermogravimetric Analyzer for Biomass Proximate Analysis: Comparison of Chip and Ground Biomass Models

2024. Energies, 17 (4), Art.-Nr.: 800. doi:10.3390/en17040800 -

Fonseca, F. G.; Funke, A.

Modeling of Liquid–Vapor Phase Equilibria of Pyrolysis Bio-oils: A Review

2024. Industrial & Engineering Chemistry Research, 63 (31), 13401–13420. doi:10.1021/acs.iecr.4c00775 -

Wen, X.; Shamooni, A.; Stein, O. T.; Tainaka, K.; Meller, D.; Kronenburg, A.; Kempf, A. M.; Hasse, C.

A four-fuel-stream flamelet model for large-eddy simulation of piloted pulverized coal/ammonia co-combustion

2024. Proceedings of the Combustion Institute, 40 (1-4), 105470. doi:10.1016/j.proci.2024.105470 -

Parku, G. K.; Pulicanti, S. R.; Funke, A.; Dahmen, N.

Phase Equilibria Aided Optimization of Levoglucosan Extraction during Condensation of Fast Pyrolysis Bio-Oils

2024. Energy and Fuels, 38 (15), 14343–14350. doi:10.1021/acs.energyfuels.4c01097 -

Aschenbrenner, E.; Funke, A.

Numerical Validation of a Screw Conveyor Design Method

2024. Energy and Fuels, 38 (14), 13019 – 13028. doi:10.1021/acs.energyfuels.4c00189 -

Dammann, M.; Walker, S. C.; Mancini, M.; Kolb, T.

Devolatilisation of beech wood char: Kinetics from thermogravimetric analyses and drop-tube reactor experiments

2024. Fuel, 375, Art.-Nr.: 131967. doi:10.1016/j.fuel.2024.131967 -

Dammann, M.; Weber, R.; Fateev, A.; Clausen, S.; Alberti, M.; Kolb, T.; Mancini, M.

Thermal radiation at high-temperature and high-pressure conditions: Validation of HITEMP-2010 for carbon dioxide

2024. Journal of Quantitative Spectroscopy and Radiative Transfer, 329, 109121. doi:10.1016/j.jqsrt.2024.109121 -

Luu, T. D.; Shamooni, A.; Kronenburg, A.; Braig, D.; Mich, J.; Nguyen, B.-D.; Scholtissek, A.; Hasse, C.; Thäter, G.; Carbone, M.; Frohnapfel, B.; Stein, O. T.

Carrier-phase DNS study of particle size distribution effects on iron particle ignition in a turbulent mixing layer

2024. Proceedings of the Combustion Institute, 40 (1-4), Art.-Nr.: 105297. doi:10.1016/j.proci.2024.105297 -

Zirwes, T.; Eckart, S.; Zhang, F.; Kaiser, T. L.; Oberleithner, K.; Stein, O. T.; Bockhorn, H.; Kronenburg, A.

Structure and dynamics of hexagonal cells in H

2024. Proceedings of the Combustion Institute, 40 (1-4), 105332. doi:10.1016/j.proci.2024.105332 -

Thäter, G.; Carbone, M.; Luu, T.-D.; Stein, O. T.; Frohnapfel, B.

The influence of clustering in homogeneous isotropic turbulence on the ignition behavior of iron particles

2024. Proceedings of the Combustion Institute, 40 (1-4), 105348. doi:10.1016/j.proci.2024.105348 -

May, N.; Baumann, W.; Hauser, M.; Yin, Z.; Geigle, K. P.; Stapf, D.

Degradation and Recondensation of Metal Oxide Nanoparticles in Laminar Premixed Flames

2024. Nanomaterials, 14 (12), Art.-Nr.: 1047. doi:10.3390/nano14121047 -

Dyck, A.; Böhlke, T.; Pundt, A.; Wagner, S.

Phase transformation in the Niobium Hydrogen system: Effects of elasto-plastic deformations on phase stability predicted by a thermodynamic model

2024. Scripta Materialia, 251, Art.-Nr.: 116209. doi:10.1016/j.scriptamat.2024.116209 -

Dutzi, J.; Boukis, N.; Sauer, J.

Investigating Salt Precipitation in Continuous Supercritical Water Gasification of Biomass

2024. Processes, 12 (5), Art.-Nr.: 935. doi:10.3390/pr12050935 -

del Barrio Montañés, A. A.; Senaj, V.; Kramer, T.; Sack, M.

Updates on Impact Ionisation Triggering of Thyristors

2024. Applied Sciences, 14 (10), 4196. doi:10.3390/app14104196 -

Luu, T. D.; Zhang, J.; Gärtner, J. W.; Meng, S.; Kronenburg, A.; Li, T.; Løvås, T.; Stein, O. T.

Single particle conversion of woody biomass using fully-resolved and Euler–Lagrange coarse-graining approaches

2024. Fuel, 368, Art.-Nr.: 131600. doi:10.1016/j.fuel.2024.131600 -

Parku, G. K.; Funke, A.; Dahmen, N.

Influence of selected quench media used for direct contact condensation on yield and composition of fast pyrolysis bio-oils aided by thermodynamic phase equilibria modelling

2024. Separation and Purification Technology, 341, Art.-Nr.: 126873. doi:10.1016/j.seppur.2024.126873 -

Fan, Y.; Li, Q.; Fonseca, F. G.; Song, J.; Gong, M.

Optimizing the Extraction of Sugars from Sewage Sludge Using Ultrasound Combined with Thermal–Alkali

2024. Water (Switzerland), 16 (9), Art.-Nr.: 1289. doi:10.3390/w16091289 -

Fonseca, F. G.; Funke, A.

Modeling Fast Pyrolysis of Waste Biomass: Improving Predictive Capability

2024. Energy and Fuels, 38 (10), 8762–8776. doi:10.1021/acs.energyfuels.3c05233 -

Asbahr, W.; Lamparter, R.; Rauch, R.

A Cold Flow Model of Interconnected Slurry Bubble Columns for Sorption-Enhanced Fischer–Tropsch Synthesis

2024. ChemEngineering, 8 (3), Article no: 52. doi:10.3390/chemengineering8030052 -

Silve, A.; Nazarova, N.; Wüstner, R.; Straessner, R.; Delso, C.; Frey, W.

Excess of Water Enables Efficient Lipid Extraction from Wet Pulsed-Electric Field-Treated A. protothecoides Microalgae Using Immiscible Solvents

2024. ACS Sustainable Chemistry & Engineering, 12 (20), 7683–7692. doi:10.1021/acssuschemeng.3c06966 -

Fedorov, A.; Graefe, P. A.; Perechodjuk, A.; Rauch, R.; Wohlrab, S.; Linke, D.

Development of Fe-based catalysts for CO

2024. Applied Catalysis A: General, 680, Art.-Nr.: 119749. doi:10.1016/j.apcata.2024.119749 -

Ji, M.; Chen, Y.; Wang, Y.; Zhang, F.; Li, J.; Pan, H.; Zhao, Y.; Zhang, Z.; Liu, L.

Molecular Dynamics Study on the Mechanism of Improved Tribological Properties of Nano-ZnO with Decanol Lubrication

2024. Tribology Letters, 72 (2), Art.-Nr.: 42. doi:10.1007/s11249-024-01840-w -

Canabarro, N. I.; Yeadon, D. J.; Wörner, M.; Hornung, U.; Vogel, F.; Baudouin, D.

Development of strategies for continuous desalination of weak black liquor based on phase-behaviour analysis

2024. The Journal of Supercritical Fluids, 209, Art.-Nr.: 106230. doi:10.1016/j.supflu.2024.106230 -

Baehr, C.; Meyer Muñoz, T.; Raffelt, K.; Dahmen, N.

Viscosity Reduction of Fast Pyrolysis Bio-Oil by Using CO

2024. Energy & Fuels, 38 (7), 6012–6019. doi:10.1021/acs.energyfuels.3c04201 -

Mokashi, M.; Shirsath, A. B.; Çelik, A.; Lott, P.; Müller, H.; Tischer, S.; Maier, L.; Bode, J.; Schlereth, D.; Scheiff, F.; Flick, D.; Bender, M.; Ehrhardt, K.; Deutschmann, O.

Methane pyrolysis in packed bed reactors: Kinetic modeling, numerical simulations, and experimental insights

2024. Chemical Engineering Journal, 485, Art.-Nr.: 149684. doi:10.1016/j.cej.2024.149684 -

Gusbeth, C.; Krolla, P.; Bruchmann, J.; Schwartz, T.; Müller, G.; Frey, W.

Bacterial decontamination of process liquids and paints in E-coating lines by pulsed electric field treatment

2024. Journal of Coatings Technology and Research, 21, 1385–1398. doi:10.1007/s11998-023-00901-4 -

Wörner, M.; Werner, L.; Hornung, U.; Islongo Canabarro, N.; Baudouin, D.; Dahmen, N.

The Impact of Sulfur-Containing Inorganic Compounds during the Depolymerization of Lignin by Hydrothermal Liquefaction of Black Liquor

2024. Energy & Fuels, 38 (7), 6036–6047. doi:10.1021/acs.energyfuels.3c04737 -

Wörner, M.; Barsuhn, A.; Zevaco, T.; Hornung, U.; Dahmen, N.

From Pulp to Aromatic Products─Reaction Pathways of Lignin Depolymerization

2024. Energy & Fuels, 38 (7), 6020–6035. doi:10.1021/acs.energyfuels.3c04509 -

Yang, L.; Wang, Y.; Zirwes, T.; Zhang, F.; Bockhorn, H.; Chen, Z.

Effects of Intrinsic Instabilities on the Response of Premixed Hydrogen/Air Conical Flames to Inlet Flow Perturbations

2024. Flow, Turbulence and Combustion, 112 (4), 1275–1297. doi:10.1007/s10494-024-00535-5 -

Jalalinejad, A.; Yousefi Seyf, J.; Funke, A.; Dahmen, N.

Phase Equilibrium Calculation of Bio-Oil-Related Molecules Using Predictive Thermodynamic Models

2024. Energy and Fuels, 38 (4), 3171 – 3185. doi:10.1021/acs.energyfuels.3c04395 -

Zhang, F.; Tavakkol, S.; Dercho, S.; Zhou, J.; Zirwes, T.; Zeller, M.; Vogt, J.; Zhang, R.; Bockhorn, H.; Stapf, D.

Assessment of dynamic characteristics of fluidized beds via numerical simulations

2024. Physics of Fluids, 36 (2), Art.-Nr.: 023348. doi:10.1063/5.0189519 -

E-Moghaddam, M.; Dahmen, N.; Santo, U.; Sauer, J.

Gasoline Synthesis from Biomass-Derived Syngas Comparing Different Methanol and Dimethyl Ether Pathways by Process Simulation, Based on the Bioliq Process

2024. Energy & Fuels, 38 (5), 4229–4243. doi:10.1021/acs.energyfuels.3c04524 -

Prestigiacomo, C.; Fan, Y.; Hornung, U.; Dahmen, N.; Scialdone, O.; Galia, A.

Hydrothermal liquefaction of sewage sludge: use of HCOOH and KOH to improve the slurry pumpability in a continuously operated plant

2024. Heliyon, 10 (4), Art.-Nr.: e26287. doi:10.1016/j.heliyon.2024.e26287 -

Kesari, A. S.; Chaganti, S. K.; Chowdhury, C.

Quantum simulation of small molecules for multiple applications

2024. Chemical Physics, 580, Art.-Nr.: 112195. doi:10.1016/j.chemphys.2024.112195 -

Luu, T. D.; Shamooni, A.; Kronenburg, A.; Braig, D.; Mich, J.; Nguyen, B.-D.; Scholtissek, A.; Hasse, C.; Thäter, G.; Carbone, M.; Frohnapfel, B.; Stein, O. T.

Carrier-Phase DNS of Ignition and Combustion of Iron Particles in a Turbulent Mixing Layer

2024. Flow, Turbulence and Combustion, 112 (4), 1083–1103. doi:10.1007/s10494-023-00526-y -

Rauch, R.; Kiros, Y.; Engvall, K.; Kantarelis, E.; Brito, P.; Nobre, C.; Santos, S. M.; Graefe, P. A.

Hydrogen from Waste Gasification

2024. Hydrogen, 5 (1), 70–101. doi:10.3390/hydrogen5010006 -

Meier, R.; Zirwes, T.; Zhang, F.; Bockhorn, H.; Oliveira, A. A. M.

Numerical investigation of unsteady flame propagation assisted by low-temperature chemistry

2024. Fuel, 364, Art.-Nr.: 130895. doi:10.1016/j.fuel.2024.130895 -

Gusbeth, C.; Frey, W.

Processing liquid food with hundreds of Hertz and tens of kilovolts Comment on “Advances in pulsed electric stimuli as a physical method for treating liquid foods” by F. Zarea, N. Ghasemi, N. Bansal and H. Hosano

2024. Physics of Life Reviews, 48, 201–202. doi:10.1016/j.plrev.2024.02.001 -

Dutzi, J.; Boukis, N.; Sauer, J.

Supercritical water gasification of heavy metal contaminated plants with focus on separation of heavy metal contaminants

2024. Biomass and Bioenergy, 182, Article no: 107059. doi:10.1016/j.biombioe.2024.107059 -

Stallkamp, C.; Hennig, M.; Volk, R.; Stapf, D.; Schultmann, F.

Pyrolysis of mixed engineering plastics: Economic challenges for automotive plastic waste

2024. Waste Management, 176, 105–116. doi:10.1016/j.wasman.2024.01.035 -

Pundt, A.; Wagner, S.

Hydrogen Interactions with Defects in Materials

2024. Chemie Ingenieur Technik, 96 (1-2), 182–191. doi:10.1002/cite.202300235 -

Karger, L.; Korneychuk, S.; Bergh, W. Van den; Dreyer, S. L.; Zhang, R.; Kondrakov, A.; Janek, J.; Brezesinski, T.

Seesaw Effect of Substitutional Point Defects on the Electrochemical Performance of Single-Crystal LiNiO

2024. Chemistry of Materials, 36 (3), 1497–1512. doi:10.1021/acs.chemmater.3c02727 -

Weih, N.; Niebel, A.; Pfitzer, C.; Funke, A.; Parku, G. K.; Dahmen, N.

Operational experience with miscanthus feedstock at the bioliq® fast pyrolysis plant

2024. Journal of Analytical and Applied Pyrolysis, 177, Article no: 106338. doi:10.1016/j.jaap.2023.106338 -

Dutzi, J.; Stoll, I. K.; Boukis, N.; Sauer, J.

Screening of ten different plants in the process of supercritical water gasification

2024. Sustainable Chemistry for the Environment, 5, Art.-Nr.: 100062. doi:10.1016/j.scenv.2024.100062 -

Shekhar, S.; Chowdhury, C.

Prediction of hydrogen storage in metal-organic frameworks: A neural network based approach

2024. Results in Surfaces and Interfaces, 14, Art.-Nr.: 100166. doi:10.1016/j.rsurfi.2023.100166 -

Ghasemi, A.; Christou, T.; Kok, J. B. W.; Stelzner, B.; Zarzalis, N.

Combustion dynamics analysis of a pressurized airblast swirl burner using proper orthogonal decomposition

2024. International Journal of Spray and Combustion Dynamics, 16 (1-2), 16–32. doi:10.1177/17568277231207252 -

Zhu, J.; Zirwes, T.; Zhang, F. C.; Li, Z. J.; Zhang, Y.; Pan, J. F.

Correlation of wall heat loss with quenching distance for premixed H

2024. Chemical Engineering Science, 283, 119391. doi:10.1016/j.ces.2023.119391 -

Perret, L.; Boukis, N.; Sauer, J.

Synthesis gas fermentation at high cell density: How pH and hydrogen partial pressure affect productivity and product ratio in continuous fermentation

2024. Bioresource Technology, 391 (Part A), Art.-Nr.: 129894. doi:10.1016/j.biortech.2023.129894 -

Vadarlis, A. A.; Neukum, D.; Lemonidou, A. A.; Boukis, N.; Sauer, J.

Direct steam reforming of the product gas from ethanol gasification with supercritical water

2024. International Journal of Hydrogen Energy, 49 (A), 992–1008. doi:10.1016/j.ijhydene.2023.08.108 -

Zimmermann, J.; Raffelt, K.; Dahmen, N.

Suppressing the formation of N-heteroaromatics during hydrothermal liquefaction of proteinaceous model feedstock

2024. Biomass Conversion and Biorefinery, 14 (19), 24671–24683. doi:10.1007/s13399-023-04553-7

-

Sack, M.; Herzog, D.; Müller, G.

Blumlein-Generator with a GaN-HEMT in gate-boosted Operation as Closing Switch

2024. 2024 IEEE International Power Modulator and High Voltage Conference (IPMHVC), Indianapolis, 28th May-1st June 2024, 1–4, Institute of Electrical and Electronics Engineers (IEEE). doi:10.1109/IPMHVC55105.2024.11002829 -

Bala, E.; Hornung, U.; Dahmen, N.

Adsorption Separation of Catechol, Accompanying Guaiacol and Phenol from the Hydrothermal Liquefaction (HTL) of Lignin

2024. European Biomass Conference and Exhibition Proceedings, 769–771, ETA-Florence Renewable Energies

-

Delove Tegladza, I.; Kordorwu, V.; Kofi Parku, G.; Bentum Hammond, C.; Hammond Quarcoo, F.

Modelling studies of the diffusivity and intersolubility of semi volatile organic compounds in water

2023. The holistic approach to environment, 13 (2), 63–75. doi:10.33765/thate.13.2.3 -

Ajikashile, J. O.; Alhnidi, M.-J.; Parku, G. K.; Funke, A.; Kruse, A.

A study on the fast pyrolysis of millet and sorghum straws sourced from arid and semi-arid regions of Nigeria in a twin-screw mixing reactor

2023. Materials Science for Energy Technologies, 6, 388–398. doi:10.1016/j.mset.2023.03.007 -

Streier, R.; Wirtz, S.; Aleksandrov, K.; Gehrmann, H.-J.; Stapf, D.; Zhang, M.; Vogelbacher, M.; Matthes, J.; Scherer, V.

Determination of the statistical distribution of drag and lift coefficients of refuse derived fuel by computer vision

2023. Fuel, 352, 128847. doi:10.1016/j.fuel.2023.128847 -

Baehr, C.; Acar, R.; Hamrita, C.; Raffelt, K.; Dahmen, N.

CO

2023. Industrial & Engineering Chemistry Research, 62 (38), 15378–15385. doi:10.1021/acs.iecr.3c02070 -

Campos Fraga, M. M.; Vogt, J.; Lacerda de Oliveira Campos, B.; Schmitt, C. C.; Raffelt, K.; Dahmen, N.

Investigation of Nb

2023. Energy & Fuels, 37 (14), 10474–10492. doi:10.1021/acs.energyfuels.3c01152 -

Dutzi, J.; Boukis, N.; Sauer, J.

Energetic Assessment of SCWG Experiments with Reed Canary Grass and Ethanol Solution on Laboratory and Pilot Scale

2023. Energies, 16 (19), Article no: 6848. doi:10.3390/en16196848 -

Graf, D.; Waßmuth, J.; Rauch, R.

Co-Hydroprocessing of Fossil Middle Distillate and Bio-Derived Durene-Rich Heavy Ends under Hydrotreating Conditions

2023. Reactions, 4 (3), 531–551. doi:10.3390/reactions4030032 -

Bazgir, H.; Rostami, M. R.; Tavakkol, S.; Issaabadi, Z.; Shirazi, H. M.; Goshayeshi, B.; Van Geem, K. M.; Haghighi, M. N.; Abbas-Abadi, M. S.

The chemical process of producing activated carbon using walnut shells and plastic wastes

2023. Journal of Thermal Analysis and Calorimetry, 148, 10125–10138. doi:10.1007/s10973-023-12364-1 -

Pola, L.; Collado, S.; Wörner, M.; Hornung, U.; Díaz, M.

Eutectic solvents for the valorisation of the aqueous phase from hydrothermally liquefied black liquor

2023. Journal of Environmental Chemical Engineering, 11 (5), Art.-Nr.: 111040. doi:10.1016/j.jece.2023.111040 -

Pola, L.; Collado, S.; Wörner, M.; Hornung, U.; Díaz, M.

Valorisation of the residual aqueous phase from hydrothermally liquefied black liquor by persulphate-based advanced oxidation

2023. Chemosphere, 339, Art.-Nr.: 139737. doi:10.1016/j.chemosphere.2023.139737 -

Chen, Y.; Sheng, Y.; Wang, Y.; Ji, M.; Pan, H.; Zhang, F.; Liu, L.

Enhancing Wear Resistance and Microstructural Evolution of Brass Through Laser Shock Peening

2023. Tribology Letters, 71 (4), Art.-Nr.: 107. doi:10.1007/s11249-023-01777-6 -

Perret, L.; Boukis, N.; Sauer, J.

Influence of Increased Cell Densities on Product Ratio and Productivity in Syngas Fermentation

2023. Industrial & Engineering Chemistry Research, 62 (35), 13799–13810. doi:10.1021/acs.iecr.3c01911 -

Léon, A.; Schlabach, S.; Villanova, J.

X-ray nano-spectroscopy study of two solid oxide cells operated for long-term in steam electrolysis

2023. Journal of Power Sources, 581, Art.-Nr.: 233410. doi:10.1016/j.jpowsour.2023.233410 -

Dutzi, J.; Vadarlis, A. A.; Boukis, N.; Sauer, J.

Comparison of Experimental Results with Thermodynamic Equilibrium Simulations of Supercritical Water Gasification of Concentrated Ethanol Solutions with Focus on Water Splitting

2023. Industrial & Engineering Chemistry Research, 62 (32), 12501–12512. doi:10.1021/acs.iecr.3c01595 -

Vadarlis, A. A.; Angeli, S. D.; Lemonidou, A. A.; Boukis, N.; Sauer, J.

Catalytic Biomass Gasification in Supercritical Water and Product Gas Upgrading

2023. ChemBioEng Reviews, 10 (4), 370–398. doi:10.1002/cben.202300007 -

Freund, H.; Sauer, J.; Wachsen, O.

„Digitalisierung der Reaktionstechnik“: ein Themenfeld mit vielen Facetten!

2023. Chemie Ingenieur Technik, 95 (5), 619. doi:10.1002/cite.202370502 -

Netsch, N.; Vogt, J.; Richter, F.; Straczewski, G.; Mannebach, G.; Fraaije, V.; Tavakkol, S.; Mihan, S.; Stapf, D.

Chemical Recycling of Polyolefinic Waste to Light Olefins by Catalytic Pyrolysis

2023. Chemie Ingenieur Technik, 95 (8), 1305–1313. doi:10.1002/cite.202300078 -

Stallkamp, C.; Hennig, M.; Volk, R.; Richter, F.; Bergfeldt, B.; Tavakkol, S.; Schultmann, F.; Stapf, D.

Economic and environmental assessment of automotive plastic waste end‐of‐life options: Energy recovery versus chemical recycling

2023. Journal of Industrial Ecology, 27 (5), 1319–1334. doi:10.1111/jiec.13416 -

Zirwes, T.; Sontheimer, M.; Zhang, F.; Abdelsamie, A.; Pérez, F. E. H.; Stein, O. T.; Im, H. G.; Kronenburg, A.; Bockhorn, H.

Assessment of Numerical Accuracy and Parallel Performance of OpenFOAM and its Reacting Flow Extension EBIdnsFoam

2023. Flow, Turbulence and Combustion, 111 (2), 567–602. doi:10.1007/s10494-023-00449-8 -

Jalalinejad, A.; Seyf, J. Y.; Funke, A.; Dahmen, N.

Solvent Screening for Separation of Lignin-Derived Molecules Using the NIST-UNIFAC Model

2023. ACS Sustainable Chemistry and Engineering, 11 (20), 7863–7873. doi:10.1021/acssuschemeng.3c00906 -

Zeller, M.; Garbev, K.; Weigel, L.; Saatzer, T.; Merz, D.; Tavakkol, S.; Stapf, D.

Thermogravimetric studies, kinetic modeling and product analysis of the pyrolysis of model polymers for technical polyurethane applications

2023. Journal of analytical and applied pyrolysis, 171, Article no: 105976. doi:10.1016/j.jaap.2023.105976 -

Figueira-Galán, D.; Heupel, S.; Duelli, G.; Tomasi Morgano, M.; Stapf, D.; Requena, N.

Exploring the synergistic effects of biochar and arbuscular mycorrhizal fungi on phosphorus acquisition in tomato plants by using gene expression analyses

2023. Science of The Total Environment, 884, Art.-Nr.: 163506. doi:10.1016/j.scitotenv.2023.163506 -

Kaiser, T. L.; Varillon, G.; Polifke, W.; Zhang, F.; Zirwes, T.; Bockhorn, H.; Oberleithner, K.

Modelling the response of a turbulent jet flame to acoustic forcing in a linearized framework using an active flame approach

2023. Combustion and Flame, 253, Art.-Nr.: 112778. doi:10.1016/j.combustflame.2023.112778 -

Zhang, F.; Wachter, S.; Zirwes, T.; Jakobs, T.; Zarzalis, N.; Trimis, D.; Kolb, T.; Stapf, D.

Effect of nozzle up-scaling on coaxial, gas-assisted atomization

2023. Physics of Fluids, 35 (4), Art.-Nr.: 043302. doi:10.1063/5.0141156 -

Zhang, M.; Vogelbacher, M.; Aleksandrov, K.; Gehrmann, H.-J.; Stapf, D.; Streier, R.; Wirtz, S.; Scherer, V.; Matthes, J.

A Novel Plenoptic Camera-Based Measurement System for the Investigation into Flight and Combustion Behavior of Refuse-Derived Fuel Particles

2023. ACS Omega, 8 (19), 16700–16712. doi:10.1021/acsomega.2c08004 -

Dammann, M.; Mancini, M.; Kolb, T.; Weber, R.

Thermal radiation at high-temperature and high-pressure conditions: Comparison of models for design and scale-up of entrained flow gasification processes

2023. Thermal Science and Engineering Progress, 42, Art.-Nr.: 101772. doi:10.1016/j.tsep.2023.101772 -

Matthes, J.; Waibel, P.; Kollmer, M.; Aleksandrov, K.; Gehrmann, H.-J.; Stapf, D.; Vogelbacher, M.

Camera based flame stability monitoring and control of multi-burner systems using deep learning based flame detection

2023. Thermal Science and Engineering Progress, 41, Artkl.Nr.: 101859. doi:10.1016/j.tsep.2023.101859 -

Buchheiser, S.; Deutschmann, M. P.; Rhein, F.; Allmang, A.; Fedoryk, M.; Stelzner, B.; Harth, S.; Trimis, D.; Nirschl, H.

Particle and Phase Analysis of Combusted Iron Particles for Energy Storage and Release

2023. Materials, 16 (5), 2009. doi:10.3390/ma16052009 -

Dutzi, J.; Boukis, N.; Sauer, J.

Process Effluent Recycling in the Supercritical Water Gasification of Dry Biomass

2023. Processes, 11 (3), Art.-Nr.: 797. doi:10.3390/pr11030797 -

Jolibois, N.; Gehrmann, H.-J.; Aleksandrov, K.; Hauser, M.; Stapf, D.; Jäger, B.; Wirtz, S.; Scherer, V.; Danz, P.; Matthes, J.; Vogelbacher, M.; Waibel, P.

Oscillating combustion of different fuel types for NOₓ reduction in grate furnaces and coal burners

2023. Fuel, 340, Art.-Nr.: 127504. doi:10.1016/j.fuel.2023.127504 -

Parku, G. K.; Krutof, A.; Funke, A.; Richter, D.; Dahmen, N.

Using Fractional Condensation to Optimize Aqueous Pyrolysis Condensates for Downstream Microbial Conversion

2023. Industrial and Engineering Chemistry Research, 62 (6), 2792–2803. doi:10.1021/acs.iecr.2c03598 -

Friesen, A.; Fritsch-Decker, S.; Mülhopt, S.; Quarz, C.; Mahl, J.; Baumann, W.; Hauser, M.; Wexler, M.; Schlager, C.; Gutmann, B.; Krebs, T.; Goßmann, A.-K.; Weis, F.; Hufnagel, M.; Stapf, D.; Hartwig, A.; Weiss, C.

Comparing the Toxicological Responses of Pulmonary Air–Liquid Interface Models upon Exposure to Differentially Treated Carbon Fibers

2023. International Journal of Molecular Sciences, 24 (3), Art.-Nr.: 1927. doi:10.3390/ijms24031927 -

Straessner, R.; Nikolausz, M.; Silve, A.; Nazarova, N.; Wuestner, R.; Papachristou, I.; Akaberi, S.; Leber, K.; Mueller, G.; Frey, W.

Holistic exploitation of pulsed electric field (PEF)-treated and lipid extracted microalgae Auxenochlorella protothecoides, utilizing anaerobic digestion (AD)

2023. Algal Research, 69, Art._Nr.: 102950. doi:10.1016/j.algal.2022.102950 -

Haas, M.; Dammann, M.; Fleck, S.; Kolb, T.

Entrained flow gasification: Impact of fuel spray distribution on reaction zone structure

2023. Fuel, 334 (2), Art.-Nr.: 126572. doi:10.1016/j.fuel.2022.126572 -

Prabhakaran, P.; Graf, F.; Koeppel, W.; Kolb, T.

Modelling and validation of energy systems with dynamically operated Power to Gas plants for gas-based sector coupling in de-central energy hubs

2023. Energy Conversion and Management, 276, Art.Nr. 116534. doi:10.1016/j.enconman.2022.116534 -

Hotz, C.; Haas, M.; Wachter, S.; Fleck, S.; Kolb, T.

Experimental investigation on entrainment in two-phase free jets

2023. Fuel, 335, Article no: 126912. doi:10.1016/j.fuel.2022.126912 -

Eckart, S.; Pio, G.; Zirwes, T.; Zhang, F.; Salzano, E.; Krause, H.; Bockhorn, H.

Impact of carbon dioxide and nitrogen addition on the global structure of hydrogen flames

2023. Fuel, 335, Art.-Nr.: 126929. doi:10.1016/j.fuel.2022.126929 -

Tavakkol, S.; Zirwes, T.; Denev, J. A.; Bockhorn, H.; Stapf, D.

Modeling of radiation heat transfer in dense-bed flows of solids in indirectly heated rotary kilns

2023. Thermal Science and Engineering Progress, 38, Article no: 101545. doi:10.1016/j.tsep.2022.101545 -

Fan, Y.; Meyer, L.; Gong, M.; Krause, B.; Hornung, U.; Dahmen, N.

Understanding the fate of nitrogen during catalytic hydrothermal liquefaction of sewage sludge

2023. Fuel, 339, Art.-Nr.: 126948. doi:10.1016/j.fuel.2022.126948 -

Zhang, F.; Zirwes, T.; Wachter, S.; Jakobs, T.; Habisreuther, P.; Zarzalis, N.; Trimis, D.; Kolb, T.; Bockhorn, H.; Stapf, D.

Numerical simulations of air-assisted primary atomization at different air-to-liquid injection angles

2023. International journal of multiphase flow, 158, Art.-Nr.: 104304. doi:10.1016/j.ijmultiphaseflow.2022.104304 -

Zhu, J.; Pan, J.; Zhang, F.; Zirwes, T.; Ojo, A. O.; Li, F.

Near-wall dynamics of premixed methane/air flames

2023. Fuel, 331, Art.Nr. 125774. doi:10.1016/j.fuel.2022.125774 -

Jung, D.; Duman, G.; Zimmermann, M.; Kruse, A.; Yanik, J.

Hydrothermal carbonization of fructose—effect of salts and reactor stirring on the growth and formation of carbon spheres

2023. Biomass Conversion and Biorefinery, 13, 6281–6297. doi:10.1007/s13399-021-01782-6

-

Mello José, Á. H.; Raffelt, K.; Campos Fraga, M. M.; Schmitt, C. C.; Brambilla Rodrigues, R. de C. L.; Dahmen, N.

Fast Pyrolysis and Catalytic Upgrading of Corncob Biomass for Fuel Production

2023. European Biomass Conference and Exhibition Proceedings, 986–987, ETA-Florence Renewable Energies -

Sack, M.; Herzog, D.; Hochberg, M.; Loisch, G.; Obier, F.; Mueller, G.

Pulse Generator with an Individual Power Supply per Stage

2023. 2023 IEEE Pulsed Power Conference (PPC), 1–4, Institute of Electrical and Electronics Engineers (IEEE). doi:10.1109/PPC47928.2023.10311026 -

Schwagerus, A.; Habisreuther, P.; Zarzalis, N.

Numerical calculation of the lean-blow-out in a multi-jet burner

2023. High Performance Computing in Science and Engineering ’21 : Transactions of the High Performance Computing Center, Stuttgart (HLRS) 2021. Ed.: W. Nagel, 497–511, Springer International Publishing. doi:10.1007/978-3-031-17937-2_31 -

Alves, V. R. S.; Meyer, D. C.; Moreira, R.; Sousa, A. P. S.; Ushima, A. H.; Raffelt, K.

Thermochemical Biomass Conversion Process in a Small-Scale Fluidized Bed Reactor: Fast Pyrolysis of Eucalyptus Wood and Gasification of Sugarcane Straw

2023. European Biomass Conference and Exhibition Proceedings, 527 – 529, ETA-Florence Renewable Energies -

Poppenborg, R.; Beisswanger, K.; Hotz, C.; Förderer, K.; Kolb, T.; Hagenmeyer, V.

Dynamic Mapping for Evolutionary Algorithm Based Optimization of Energy Hub Gas Scheduling

2023. 2023 IEEE 11th International Conference on Smart Energy Grid Engineering (SEGE), 206–211, Institute of Electrical and Electronics Engineers (IEEE). doi:10.1109/SEGE59172.2023.10274571

-

Carriel Schmitt, C.; Rapp, M.; Voigt, A.; De Carvalho, M. dos S.

Selective Detection of Aromatic Compounds with a Re-Designed Surface Acoustic Wave Sensor System Using a Short Packed Column

2022. Coatings, 12 (11), Art.-Nr.: 1666. doi:10.3390/coatings12111666 -

Vogelbacher, M.; Zhang, M.; Aleksandrov, K.; Gehrmann, H.-J.; Matthes, J.

Two- and Three-Dimensional Benchmarks for Particle Detection from an Industrial Rotary Kiln Combustion Chamber Based on Light-Field-Camera Recording

2022. Data, 7 (12), 179. doi:10.3390/data7120179 -

Sack, M.; Ruf, J.; Herzog, D.; Müller, G.

Modelling of a Resonant Charging Circuit for a Solid-State Marx Generator

2022. Applied Sciences, 12 (23), Art.-Nr.: 12481. doi:10.3390/app122312481 -

Stephan, F.; Gross, M.; Grebinyk, A.; Aboulbanine, Z.; Amirkhanyan, Z.; Budach, V.; Ehrhardt, V. H.; Faus-Golfe, A.; Frohme, M.; Germond, J.-F.; Good, J. D.; Grüner, F.; Kaul, D.; Krasilnikov, M.; Leavitt, R.; Leemans, W.; Li, X.; Loisch, G.; Müller, F.; Müller, G.; Obier, F.; Oppelt, A.; Philipp, S.; Qian, H.; Reindl, J.; Riemer, F.; Sack, M.; Schmitz, M.; Schnautz, T.; Schüller, A.; Staufer, T.; Stegmann, C.; Tsakanova, G.; Vozenin, M.-C.; Weise, H.; Worm, S.; Zips, D.

FLASHlab@PITZ : New R&D platform with unique capabilities for electron FLASH and VHEE radiation therapy and radiation biology under preparation at PITZ

2022. Physica Medica, 104, 174–187. doi:10.1016/j.ejmp.2022.10.026 -

Papachristou, I.; Zhang, S.; Gorte, O.; Ochsenreither, K.; Wüstner, R.; Nazarova, N.; Frey, W.; Silve, A.

Direct transesterification of microalgae after Pulsed Electric Field ( PEF ) treatment

2022. Journal of Chemical Technology & Biotechnology, 98 (3), 642–650. doi:10.1002/jctb.7293 -

Zimmermann, J.; Chiaberge, S.; Iversen, S. B.; Raffelt, K.; Dahmen, N.

Sequential Extraction and Characterization of Nitrogen Compounds after Hydrothermal Liquefaction of Sewage Sludge

2022. Energy & Fuels, 36 (23), 14292–14303. doi:10.1021/acs.energyfuels.2c02622 -

Perret, L.; Boukis, N.; Sauer, J.

Methods of reaction and reactor engineering to adjust product ratios and increase efficiency of syngas fermentation with Clostridium ljungdahlii

2022. Chemie Ingenieur Technik, 94 (9), 1252. doi:10.1002/cite.202255034 -

Thor, N.; Bernauer, J.; Petry, N.-C.; Ionescu, E.; Riedel, R.; Pundt, A.; Kleebe, H.-J.

Microstructural evolution of Si(HfₓTa₁₋ₓ)(C)N polymer-derived ceramics upon high-temperature anneal

2022. Journal of the European Ceramic Society, 43 (4), 1417–1431. doi:10.1016/j.jeurceramsoc.2022.11.060 -

Zhang, F.; Zirwes, T.; Häber, T.; Bockhorn, H.; Trimis, D.; Suntz, R.; Stapf, D.

Correlation of heat loss with quenching distance during transient flame-Wall interaction

2022. Proceedings of the Combustion Institute, 39 (2), 2037–2045. doi:10.1016/j.proci.2022.10.010 -

Guo, B.; Hornung, U.; Zhang, S.; Dahmen, N.

Techno‐Economic Assessment of a Microalgae Biorefinery

2022. Chemie Ingenieur Technik, 95 (6), 950–954. doi:10.1002/cite.202200007 -

Baleeiro, F. C. F.; Raab, J.; Kleinsteuber, S.; Neumann, A.; Sträuber, H.

Mixotrophic chain elongation with syngas and lactate as electron donors

2022. Microbial Biotechnology, 16 (2), 322–336. doi:10.1111/1751-7915.14163 -

Fan, Y.; Hoffmann, A.; Hornung, U.; Raffelt, K.; Zevaco, T. A.; Dahmen, N.

Hydrothermal, catalyst-free production of a cyclic dipeptide from lysine

2022. Journal of Analytical and Applied Pyrolysis, 168, Art.-Nr.: 105792. doi:10.1016/j.jaap.2022.105792 -

Zhang, M.; Vogelbacher, M.; Hagenmeyer, V.; Aleksandrov, K.; Gehrmann, H.-J.; Matthes, J.

3D Refuse-derived Fuel Particle Tracking-by-Detection Using a Plenoptic Camera System

2022. IEEE Transactions on Instrumentation and Measurement, 71, Art.Nr. 5024815. doi:10.1109/TIM.2022.3217858 -

Matthes, J.; Kollmer, M.; Eberhard, M.; Hagenmeyer, V.; Kolb, T.

A Highspeed‐Camera Based Measurement System for the High‐Pressure Entrained‐Flow Gasification

2022. Chemical Engineering & Technology, 45 (12), 2313–2322. doi:10.1002/ceat.202200434 -

Fonseca, F. G.; Anca-Couce, A.; Funke, A.; Dahmen, N.

Challenges in Kinetic Parameter Determination for Wheat Straw Pyrolysis

2022. Energies, 15 (19), Art.-Nr.: 7240. doi:10.3390/en15197240 -

Perret, L.; Lacerda de Oliveira Campos, B.; Herrera Delgado, K.; Zevaco, T. A.; Neumann, A.; Sauer, J.

CO

2022. Chemie Ingenieur Technik, 94 (11), 1667–1687. doi:10.1002/cite.202200153 -

Haas, M.; Fleck, S.; Böning, D.; Santo, U.; Kolb, T.

Entrained‐flow gasification of pyrolysis oil – Influence of flame structure on fuel conversion

2022. Chemie Ingenieur Technik, 94 (9), 1294–1294. doi:10.1002/cite.202255060 -

Jin, O.; Shang, Y.; Huang, X.; Szabó, D. V.; Le, T. T.; Wagner, S.; Klassen, T.; Kübel, C.; Pistidda, C.; Pundt, A.

Transformation Kinetics of LiBH

2022. Molecules, 27 (20), 7005. doi:10.3390/molecules27207005 -

Wieland, C.; Weis, C.; Habisreuther, P.; Trimis, D.

3D direct pore level simulations of radiant porous burners

2022. Combustion and Flame, 245, Art.-Nr.: 112370. doi:10.1016/j.combustflame.2022.112370 -

Jakobs, T.; Wachter, S.; Haas, M.; Fleck, S.; Kolb, T.

Burner Development for High Pressure Entrained Flow Gasification

2022. Chemie - Ingenieur - Technik, 94 (9), Article no: 1215. doi:10.1002/cite.202255022 -

Shang, Y.; Jin, O.; Puszkiel, J. A.; Karimi, F.; Dansirima, P.; Sittiwet, C.; Utke, R.; Soontaranon, S.; Le, T. T.; Gizer, G.; Szabó, D. V.; Wagner, S.; Kübel, C.; Klassen, T.; Dornheim, M.; Pundt, A.; Pistidda, C.

Effects of metal-based additives on dehydrogenation process of 2NaBH

2022. International Journal of Hydrogen Energy, 47 (89), 37882–37894. doi:10.1016/j.ijhydene.2022.08.293 -

Kansy, M.; Neuner, P.; Bajohr, S.; Rauch, R.; Kolb, T.

Vergleich verschiedener Ansätze zur nachhaltigen Olefinproduktion nach dem MtO‐ und FT‐Verfahren

2022. Chemie Ingenieur Technik, 95 (9), 1476–1481. doi:10.1002/cite.202200032 -

Delso, C.; Silve, A.; Wüstner, R.; Nazarova, N.; Álvarez, I.; Raso, J.; Frey, W.

Post-incubation pH Impacts the Lipid Extraction Assisted by Pulsed Electric Fields from Wet Biomass of Auxenochlorella protothecoides

2022. ACS Sustainable Chemistry & Engineering, 10 (37), 12448–12456. doi:10.1021/acssuschemeng.2c04016 -

Fan, Y.; Prestigiacomo, C.; Gong, M.; Tietz, T.; Hornung, U.; Dahmen, N.

Comparative investigation on the value-added products obtained from continuous and batch hydrothermal liquefaction of sewage sludge

2022. Frontiers in Environmental Science, 10, Art.Nr. 996353. doi:10.3389/fenvs.2022.996353 -

Fan, Y.; Hornung, U.; Dahmen, N.

Hydrothermal liquefaction of sewage sludge for biofuel application: A review on fundamentals, current challenges and strategies

2022. Biomass and Bioenergy, 165, Art.-Nr.: 106570. doi:10.1016/j.biombioe.2022.106570 -

Su, Y.; Guo, B.; Hornung, U.; Dahmen, N.

FeCl₃-supported solvothermal liquefaction of Miscanthus in methanol

2022. Energy, 258, Art.-Nr.: 124971. doi:10.1016/j.energy.2022.124971 -

Prestigiacomo, C.; Zimmermann, J.; Hornung, U.; Raffelt, K.; Dahmen, N.; Scialdone, O.; Galia, A.

Effect of transition metals and homogeneous hydrogen producers in the hydrothermal liquefaction of sewage sludge

2022. Fuel Processing Technology, 237, Art.-Nr.: 107452. doi:10.1016/j.fuproc.2022.107452 -

Campos Fraga, M. M.; Lacerda de Oliveira Campos, B.; Hendrawidjaja, H.; Carriel Schmitt, C.; Raffelt, K.; Dahmen, N.

Fast Pyrolysis Oil Upgrading via HDO with Fe-Promoted Nb₂O₅-Supported Pd-Based Catalysts

2022. Energies, 15 (13), Art.-Nr.: 4762. doi:10.3390/en15134762 -

Zhang, F.; Zirwes, T.; Wang, Y.; Chen, Z.; Bockhorn, H.; Trimis, D.; Stapf, D.

Dynamics of Premixed Hydrogen/Air Flames in Unsteady Flow

2022. Physics of Fluids, 34 (8), Art.-Nr.: 085121. doi:10.1063/5.0098883 -

Sauerschell, S.; Bajohr, S.; Kolb, T.

Methanation Pilot Plant with a Slurry Bubble Column Reactor: Setup and First Experimental Results

2022. Energy & Fuels, 36 (13), 7166–7176. doi:10.1021/acs.energyfuels.2c00655 -

Casel, M.; Oberleithner, K.; Zhang, F.; Zirwes, T.; Bockhorn, H.; Trimis, D.; Kaiser, T. L.

Resolvent-based modelling of coherent structures in a turbulent jet flame using a passive flame approach

2022. Combustion and Flame, 236, Art.-Nr.: 111695. doi:10.1016/j.combustflame.2021.111695 -

Netsch, N.

Recycling of polystyrene-based external thermal insulation composite systems - Application of combined mechanical and chemical recycling

2022. Waste management, (150), 141–150. doi:10.1016/j.wasman.2022.07.001 -

Mätzing, H.

A computational fluid dynamics study of flame gas sampling in horizontal dilution tubes

2022. Flow, 2, Art.-Nr.: E17. doi:10.1017/flo.2022.10 -

Neuner, P.; Graf, D.; Netsch, N.; Zeller, M.; Herrmann, T.-C.; Stapf, D.; Rauch, R.

Chemical Conversion of Fischer-Tropsch Waxes and Plastic Waste Pyrolysis Condensate to Lubricating Oil and Potential Steam Cracker Feedstock

2022. Reactions, 3 (3), 352–373. doi:10.3390/reactions3030026 -

Kohansal, K.; Sharma, K.; Haider, M. S.; Toor, S. S.; Castello, D.; Rosendahl, L. A.; Zimmermann, J.; Pedersen, T. H.

Hydrotreating of bio-crude obtained from hydrothermal liquefaction of biopulp: effects of aqueous phase recirculation on the hydrotreated oil

2022. Sustainable Energy and Fuels, 6 (11), 2805–2822. doi:10.1039/D2SE00399F -

Jin, O.; Shang, Y.; Huang, X.; Mu, X.; Szabó, D. V.; Le, T. T.; Wagner, S.; Kübel, C.; Pistidda, C.; Pundt, A.

Microstructural Study of MgB2 in the LiBH4-MgH2 Composite by Using TEM

2022. Nanomaterials, 12 (11), 1893. doi:10.3390/nano12111893 -

Christou, T.; Stelzner, B.; Zarzalis, N.

Spray response on a model prefilmer under unsteady airflows of various frequencies

2022. International Journal of Spray and Combustion Dynamics, 14 (1-2), 9 S. doi:10.1177/17568277221092987 -

Koutsonikolas, D.; Karagiannakis, G.; Plakas, K.; Chatzis, V.; Skevis, G.; Giudicianni, P.; Amato, D.; Sabia, P.; Boukis, N.; Stoll, K.

Membrane and Electrochemical Based Technologies for the Decontamination of Exploitable Streams Produced by Thermochemical Processing of Contaminated Biomass

2022. Energies, 15 (7), Art. Nr.: 2683. doi:10.3390/en15072683 -

Karp, S. G.; Schmitt, C. C.; Moreira, R.; de Oliveira Penha, R.; de Mello, A. F. M.; Herrmann, L. W.; Soccol, C. R.

Sugarcane Biorefineries: Status and Perspectives in Bioeconomy

2022. BioEnergy Research, 15, 1842–1853. doi:10.1007/s12155-022-10406-4 -

Zhang, F.; Kurjata, M.; Sebbar, N.; Zirwes, T.; Fedoryk, M.; Harth, S.; Wang, R.; Habisreuther, P.; Trimis, D.; Bockhorn, H.

Numerical Study on Flame Stabilization and NO

2022. Energy and Fuels, 36 (7), 4094–4106. doi:10.1021/acs.energyfuels.1c04007 -

Grafmüller, J.; Böhm, A.; Zhuang, Y.; Spahr, S.; Müller, P.; Otto, T. N.; Bucheli, T. D.; Leifeld, J.; Giger, R.; Tobler, M.; Schmidt, H.-P.; Dahmen, N.; Hagemann, N.

Wood Ash as an Additive in Biomass Pyrolysis: Effects on Biochar Yield, Properties, and Agricultural Performance

2022. ACS Sustainable Chemistry & Engineering, 10 (8), Artk.Nr.: 2720–2729. doi:10.1021/acssuschemeng.1c07694 -

Santos, T. M.; Silva, W. R. da; Carregosa, J. de C.; Schmitt, C. C.; Moreira, R.; Raffelt, K.; Dahmen, N.; Wisniewski, A., Jr.

Thermal Conversion of Sugarcane Bagasse Coupled with Vapor Phase Hydrotreatment over Nickel-Based Catalysts: A Comprehensive Characterization of Upgraded Products

2022. Catalysts, 12 (4), 355. doi:10.3390/catal12040355 -

Zhang, Y.; Soldatov, S.; Papachristou, I.; Nazarova, N.; Link, G.; Frey, W.; Silve, A.

Pulsed microwave pretreatment of fresh microalgae for enhanced lipid extraction

2022. Energy, 248, Art.-Nr.: 123555. doi:10.1016/j.energy.2022.123555 -

Baehr, C.; Smith, G. J.; Sleeman, D.; Zevaco, T. A.; Raffelt, K.; Dahmen, N.

Aldehydes and ketones in pyrolysis oil: analytical determination and their role in the aging process

2022. RSC Advances, 12 (12), 7374–7382. doi:10.1039/D1RA08899H -

Wachter, S.; Jakobs, T.; Kolb, T.

Mass Flow Scaling of Gas-Assisted Coaxial Atomizers

2022. Applied Sciences (Switzerland), 12 (4), Art.-Nr.: 2123. doi:10.3390/app12042123 -

Frey, W.; Nick, P.

Einsatz von Elektroimpulsen für die Biotechnologie von Mikroalgen

2022. BioSpektrum, 28 (1), 94–96. doi:10.1007/s12268-022-1688-7 -

Halim, R.; Papachristou, I.; Chen, G. Q.; Deng, H.; Frey, W.; Posten, C.; Silve, A.

The effect of cell disruption on the extraction of oil and protein from concentrated microalgae slurries

2022. Bioresource technology, 346, 126597. doi:10.1016/j.biortech.2021.126597 -

Guo, B.; Yang, B.; Weil, P.; Zhang, S.; Hornung, U.; Dahmen, N.

The Effect of Dichloromethane on Product Separation during Continuous Hydrothermal Liquefaction of Chlorella vulgaris and Aqueous Product Recycling for Algae Cultivation

2022. Energy & fuels, 36 (2), 922–931. doi:10.1021/acs.energyfuels.1c02523 -

Guo, B.; Yang, B.; Su, Y.; Zhang, S.; Hornung, U.; Dahmen, N.

Screening and Optimization of Microalgae Biomass and Plastic Material Coprocessing by Hydrothermal Liquefaction

2022. ACS ES&T Engineering, 2 (1), 65–77. doi:10.1021/acsestengg.1c00261 -

Krust, D.; Gusbeth, C.; Müller, A. S. K.; Scherer, D.; Müller, G.; Frey, W.; Nick, P.

Biological signalling supports biotechnology – Pulsed electric fields extract a cell-death inducing factor from Chlorella vulgaris

2022. Bioelectrochemistry, 143, 107991. doi:10.1016/j.bioelechem.2021.107991 -

Stockschläder, J.; Quicker, P.; Baumann, W.; Wexler, M.; Stapf, D.; Beckmann, M.; Thiel, C.; Hoppe, H.

Thermal treatment of carbon-fibre-reinforced polymers (Part 2: Energy recovery and feedstock recycling)

2022. Waste Management and Research, 40 (6), 685–697. doi:10.1177/0734242X211038192 -

Soares Dias, A. P.; Gomes Fonseca, F.; Catarino, M.; Gomes, J.

Biodiesel Glycerin Valorization into Oxygenated Fuel Additives

2022. Catalysis Letters, 152, 513–522. doi:10.1007/s10562-021-03646-0

-

Ruf, J.; Barnes, M. J.; Kramer, T.; Sack, M.

Improvements of a Branch Module for an Inductive Voltage Adder Based on Measurements and Circuit Simulations

2022. 2022 IEEE International Power Modulator and High Voltage Conference (IPMHVC), 76–79, Institute of Electrical and Electronics Engineers (IEEE). doi:10.1109/IPMHVC51093.2022.10099414 -

Sack, M.; Herzog, D.; Ruf, J.; Mueller, G.

Resonant Charging Circuit for a Semiconductor-Based Marx Generator for an Electroporation Device

2022. IEEE International Power Modulator and High Voltage Conference (IPMHVC), Knoxville, TN, June 19-236, 2022, 108–111, Institute of Electrical and Electronics Engineers (IEEE). doi:10.1109/IPMHVC51093.2022.10099422 -

Bologa, A.

Influence of electrode system geometry on the efficiency of particle collection of a compact electrostatic precipitator for small scale biomass combustion

2022. Lecture Notes in Electrical Engineering, Springer -

Wörner, M.; Hornung, U.; Dahmen, N.

Hydrothermal liquefaction of black liquor

2022. European Biomass Conference and Exhibition Proceedings, 30th European Biomass Conference and Exhibition, EUBCE 2022, Virtual, Online, 9th May 2022 - 12th May 2022, 867–874, ETA-Florence Renewable Energies -

Schmitt, C. C.; Nguyen, K.; Schmitt, N.; Moreira, R.; Raffelt, K.; Hornung, U.; Dahmen, N.

Platform chemicals from hydrothermal liquefaction of sugarcane bagasse and sugarcane straw

2022. European Biomass Conference and Exhibition Proceedings, 30th European Biomass Conference and Exhibition, EUBCE 2022, Virtual, Online, 9th May 2022 - 12th May 2022, 951–953, ETA-Florence Renewable Energies -

Poppenborg, R.; Chlosta, M.; Ruf, J.; Hotz, C.; Düpmeier, C.; Kolb, T.; Hagenmeyer, V.

Energy Hub Gas: A Modular Setup for the Evaluation of Local Flexibility and Renewable Energy Carriers Provision

2022. 2022 IEEE 10th International Conference on Smart Energy Grid Engineering (SEGE), 33–41, Institute of Electrical and Electronics Engineers (IEEE). doi:10.1109/SEGE55279.2022.9889751

-

Wang, X.; Funke, A.; Cheng, Y.-J.; Song, F.; Yin, S.; Liang, S.; Zuo, X.; Gao, J.; Müller-Buschbaum, P.; Xia, Y.

Continuous fast pyrolysis synthesis of TiO₂/C nanohybrid lithium-ion battery anode

2021. Nano select, 2 (9), 1770–1778. doi:10.1002/nano.202100015 -

Schmitt, C. C.; Fonseca, F. G.; Fraga, M. M. C.; Wisniewski, J., Alberto; Karp, S.; José, Á. H. M.; Rodrigues, R. C. L. B. L.; Moreira, R.; Hirayama, D. E.; Raffelt, K.; Dahmen, N.

Thermochemical and catalytic conversion technologies for the development of Brazilian biomass utilization

2021. Catalysts, 11 (12), 1549. doi:10.3390/catal11121549 -

Freund, H.; Sauer, J.; Wachsen, O.

„Circular Economy” – ein neues und zugleich altes Arbeitsgebiet der Reaktionstechnik

2021. Chemie - Ingenieur - Technik, 93 (5), 735. doi:10.1002/cite.202170502 -

Gehrmann, H.-J.; Jäger, B.; Wirtz, S.; Scherer, V.; Aleksandrov, K.; Hauser, M.; Stapf, D.; Pollmeier, G.; Danz, P.

Oscillating Combustion - Primary Measure to Reduce Nitrogen Oxide in a Grate Furnace - Experiments and Simulations

2021. Processes, 9 (12), Article no: 2210. doi:10.3390/pr9122210 -

Straczewski, G.; Mai, R.; Gerhards, U.; Garbev, K.; Leibold, H.

Catalytic Tar Conversion in Two Different Hot Syngas Cleaning Systems

2021. Catalysts, 11 (10), Article no: 1231. doi:10.3390/catal11101231 -

Zirwes, T.; Zhang, F.; Habisreuther, P.; Hansinger, M.; Bockhorn, H.; Pfitzner, M.; Trimis, D.

Correction to: Quasi-DNS Dataset of a Piloted Flame with Inhomogeneous Inlet Conditions

2021. Flow, turbulence and combustion, 107 (2), 517. doi:10.1007/s10494-021-00244-3 -

Fonseca, F. G.; Soares Dias, A. P.

Almond shells: Catalytic fixed-bed pyrolysis and volatilization kinetics

2021. Renewable Energy, 180, 1380–1390. doi:10.1016/j.renene.2021.08.104 -

Schlundt, J.; Soldatov, S.; Frey, W.; Link, G.; Baumann, K.; Jelonnek, J.; Sack, M.; Hochberg, M.; Silve, A.

Conception and Development of a Pulsed Microwave Applicator for Exposure of Fresh Microalgae Biomass

2021. IEEE Transactions on Plasma Science, 49 (9). doi:10.1109/TPS.2021.3101943 -

Zeller, M.; Netsch, N.; Richter, F.; Leibold, H.; Stapf, D.

Chemical Recycling of Mixed Plastic Wastes by Pyrolysis - Pilot Scale Investigations

2021. Chemie - Ingenieur - Technik, 93 (11), 1763–1770. doi:10.1002/cite.202100102 -

Kohansal, K.; Sharma, K.; Toor, S. S.; Sanchez, E. L.; Zimmermann, J.; Aistrup Rosendahl, L.; Pedersen, T. H.

Bio-Crude Production Improvement during Hydrothermal Liquefaction of Biopulp by Simultaneous Application of Alkali Catalysts and Aqueous Phase Recirculation

2021. Energies, 14 (15), Art.-Nr.: 4492. doi:10.3390/en14154492 -

Hotz, C.; Haas, M.; Wachter, S.; Fleck, S.; Kolb, T.

Two-phase free jet model of an atmospheric entrained flow gasifier

2021. Fuel, 304, Art.-Nr.: 121392. doi:10.1016/j.fuel.2021.121392 -

Wachter, S.; Jakobs, T.; Kolb, T.

Comparison of Central Jet and Annular Sheet Atomizers at Identical Gas Momentum Flows

2021. Industrial & engineering chemistry research, 60 (30), 11502–11512. doi:10.1021/acs.iecr.1c01526 -

Niebel, A.; Funke, A.; Pfitzer, C.; Dahmen, N.; Weih, N.; Richter, D.; Zimmerlin, B.

Fast Pyrolysis of Wheat Straw - Improvements of Operational Stability in 10 Years of Bioliq Pilot Plant Operation

2021. Energy and Fuels, 35 (14), 11333–11345. doi:10.1021/acs.energyfuels.1c00851 -

Henrich, E.; Dahmen, N.; Pitter, S.; Sauer, J.

30 Jahre Institut für Heiße Chemie im Kernforschungszentrum Karlsruhe [30 Years Institute for Hot Chemistry at the Nuclear Research Center Karlsruhe]

2021. Chemie - Ingenieur - Technik, 93 (11), 1667–1687. doi:10.1002/cite.202100064 -

Obeid, F.; Van, T. C.; Guo, B.; Surawski, N. C.; Hornung, U.; Brown, R. J.; Ramirez, J. A.; Thomas-Hall, S. R.; Stephens, E.; Hankamer, B.; Rainey, T.

The fate of nitrogen and sulphur during co-liquefaction of algae and bagasse: Experimental and multi-criterion decision analysis

2021. Biomass and bioenergy, 151, Art.Nr. 106119. doi:10.1016/j.biombioe.2021.106119 -

Neuner, P.; Graf, D.; Mild, H.; Rauch, R.

Catalytic Hydroisomerisation of Fischer–Tropsch Waxes to Lubricating Oil and Investigation of the Correlation between Its Physical Properties and the Chemical Composition of the Corresponding Fuel Fractions

2021. Energies, 14 (14), Art.: 4202. doi:10.3390/en14144202 -

Tonpakdee, P.; Hongrapipat, J.; Siriwongrungson, V.; Pang, S.; Rauch, R.; Messner, M.; Henrich, C.; Pessl, P.; Dichand, M.

Replacement of Palm Methyl Ester to Rapeseed Methyl Ester for Tar Removal in the Nong Bua Dual Fluidized Bed Gasification Power Plant

2021. IOP conference series / Earth and environmental science, 801 (1), Art.-Nr.: 012021. doi:10.1088/1755-1315/801/1/012021 -

Hagen, F. P.; Bockhorn, H.; Störmer, H.; Loukou, A.; Suntz, R.; Trimis, D.

Nanostructural and morphological characteristics of single soot aggregates during low-temperature oxidation

2021. Proceedings of the Combustion Institute, 38 (1), 1153–1161. doi:10.1016/j.proci.2020.06.338 -

Hufnagel, M.; May, N.; Wall, J.; Wingert, N.; Garcia-Käufer, M.; Arif, A.; Hübner, C.; Berger, M.; Mülhopt, S.; Baumann, W.; Weis, F.; Krebs, T.; Becker, W.; Gminski, R.; Stapf, D.; Hartwig, A.

Impact of Nanocomposite Combustion Aerosols on A549 Cells and a 3D Airway Model

2021. Nanomaterials, 11 (7), Art. Nr.: 1685. doi:10.3390/nano11071685 -