Gas Turbines | High Temperature Materials

The necessary significant acceleration in the development of new materials is to be expected, if the properties of materials can be predicted as a function of the material composition and the manufacturing process. In cooperation with the Helmholtz Centers Jülich, Berlin and DLR a research approach at KIT is chosen, which thoroughly connects the close interaction between the calculation and the analytical and manufacturing methods of the electronical, mechanical and thermal properties of material systems, structural elements and large components – from atomic to macroscopic scale. This strategy, in terms of strengthening modelling, simulation and verification methods is a new form of co-operation in the network of the Helmholtz Centers and for the first time a stringent overall approach to a cross-sector research in the material development.

Purpose focused material design and material tailoring for the specific application go hand in hand, by incorporating results of the modeling into the material development and vice versa by establishing direct feedback of the results from the characterization or analysis into the modeling.

Results are obtained by dedicated analytical tools resolving the chemical and physical processes relevant in the synthesis and application of pertinent materials, as well as by multi scale computational materials design, process simulation, and validated live cycle modelling.

Publications

-

Wang, J.; Peter, N. J.; Heilmaier, M.; Schwaiger, R.

A micromechanical investigation of plasticity in ordered NbMoCrTiAl and disordered TaNbHfZrTi refractory compositionally complex alloys at room temperature

2026. International Journal of Plasticity, 197, 104593. doi:10.1016/j.ijplas.2025.104593 -

Boroojerdi, M.; Camacho, D.; Breitzke, H.; Nurak, I.; Widenmeyer, M.; Xie, W.; Pundt, A.; Buntkowsky, G.; Riedel, R.; Ionescu, E.

Synthesis and thermal properties of dense Si─Al─C─N‐based polymer‐derived ceramics

2026. International Journal of Applied Ceramic Technology, 23 (1). doi:10.1111/ijac.70119 -

Liu, J.; Zhang, K.; Bermingham, M. J.; Fraser, H. L.; Hodgson, P.; Heilmaier, M.; Boretti, A.; Zhu, Y.; Huang, A.

Fatigue and damage tolerance performance of additively-manufactured titanium alloys for structural application: A comprehensive review

2026. Materials Science and Engineering: R: Reports, 167, Article no: 101135. doi:10.1016/j.mser.2025.101135

-

Bandla, D. S.; H. Chokshi, A.

On the creep behaviour of Ni based binary solid solution alloys

2025. Philosophical Magazine, 105 (22), 1475–1499. doi:10.1080/14786435.2025.2498487 -

Rahimi Chegeni, M.; Ma, W.; Riegler, S. S.; Ghavimi, A.; Rohde, M.; Yang, F.; Seifert, H. J.; Gallino, I.; Busch, R.

Thermodynamic analysis and modeling of Pd-Ni-S bulk metallic glass-forming system

2025. Acta Materialia, 294, Art.-Nr.: 121074. doi:10.1016/j.actamat.2025.121074 -

Radi, A.; Schliephake, D.; Sen, S.; Vikram, R. J.; Dixit, S.; Riedel, J. L.; Yang, L.; Tang, C.; Gorr, B.; Kauffmann, A.; Heilmaier, M.

Design of lightweight high-temperature structural materials based on Ti-Mo-Ta-Cr-Al refractory compositionally complex alloys, Part I: Phase stability and mechanical properties

2025. Journal of Alloys and Metallurgical Systems, 12, 100219. doi:10.1016/j.jalmes.2025.100219 -

Calderón, N. Z.; Becerra, C.; Campo, J. A.; Carrreño, J.; Torreblanca, H.; Stüber, M.; Ulrich, S.; Grieseler, R.

Plasma parameters analysis in DC and RF magnetron sputtering using finite element method

2025. Physica Scripta, 100 (10), Art.-Nr.: 105604. doi:10.1088/1402-4896/ae0c48 -

Jamali, A.; Kashyap, A.; Schneider, J.; Stueber, M.; Schulze, V.

Grey-box modelling for tool wear prediction in milling: Fusion of finite element insights, time-resolved cutting signals and metaheuristic feature selection

2025. Wear, 580-581, 206292. doi:10.1016/j.wear.2025.206292 -

Yu, C.; Chi, C.; Tang, C.; Gorr, B.

Numerical Study of the Stagnation-Flow Premixed Lean Hydrogen/Air Flame Stabilized at the Wall with the Focus on NO Emission and Flame-Solid Interaction

2025. Journal of Thermal Science, 34 (3), 707–719. doi:10.1007/s11630-025-2106-5 -

Burger, L.; Palkowski, H.; Ulrich, S.; Mozaffari-Jovein, H.

Influence of the Manufacturing Process and Dynamic Testing on the Residual Stress State of Additively Manufactured Ti-6Al-4V Lattice Structure Specimens

2025. JOM, 77 (10), 7519–7528. doi:10.1007/s11837-025-07508-7 -

Hinrichs, F.; Winkens, G.; Kramer, L. K.; Falcão, G.; Hahn, E. M.; Schliephake, D.; Eusterholz, M. K.; Sen, S.; Galetz, M. C.; Inui, H.; Kauffmann, A.; Heilmaier, M.

A ductile chromium–molybdenum alloy resistant to high-temperature oxidation

2025. Nature, 646 (8084), 331–337. doi:10.1038/s41586-025-09516-8 -

Tang, C.; Radi, A.; Dürrschnabel, M.; Jäntsch, U.; Klimenkov, M.; Kauffmann, A.; Heilmaier, M.; Schroer, C.; Gorr, B.

Design of lightweight high temperature structural materials based on Ti–Mo–Ta–Cr–Al refractory compositionally complex alloys, Part II: high temperature oxidation behavior

2025. Journal of Alloys and Metallurgical Systems, 12, 100217. doi:10.1016/j.jalmes.2025.100217 -

Korell, L.; Beck, K.; Chitra, A. R.; Hinrichs, F.; Oskay, C.; White, E.; Heilmaier, M.; Galetz, M. C.

Type II Hot Corrosion of Two Mo‐Si‐Ti Alloys and Mo‐Si‐B With a Salt Deposit of Mixed Na

2025. Materials and Corrosion. doi:10.1002/maco.70048 -

Dai, S.; Zhu, J.; Wu, S.; Heilmaier, M.; Zhu, Y.; Yan, X.; Huang, A.

Strength-ductility synergy in an additively manufactured oxide dispersion strengthened Inconel 718 superalloy at 650 °C

2025. Materials Science and Engineering: A, 946, Art.-Nr.: 149135. doi:10.1016/j.msea.2025.149135 -

Schliephake, D.; Ramdoss, S. R.; Vikram, R. J.; Falcão, G.; Galgon, F.; Thota, H.; Hinrichs, F.; Zenk, C.; Kauffmann, A.; Eggeler, Y.; Suwas, S.; Schwaiger, R.; Heilmaier, M.

Microstructure and mechanical properties of a laser-based directed energy deposited Mo-Si-Ti alloy

2025. Journal of Materials Science. doi:10.1007/s10853-025-11158-0 -

Kauffmann, A.; Gorr, B.; Heilmaier, M.

High temperature oxidation protection in body-centered cubic superalloys

2025. Scripta Materialia, 267, Article no: 116784. doi:10.1016/j.scriptamat.2025.116784 -

Zang, D.; Becker, J.; Betke, U.; Hasemann, G.; Khanchych, K.; Gorr, B.; Krüger, M.

Phase Evolution During High-Energy Ball Milling and Annealing of Ti-Doped Mo-V-Si-B Alloys

2025. Materials, 18 (11), Art.-Nr.: 2494. doi:10.3390/ma18112494 -

Khanchych, K.; Tang, C.; Schroer, C.; Schäfer, B.; Jung, J.; Dürrschnabel, M.; Jäntsch, U.; Gorr, B.

CALPHAD‐Guided Prediction and Interpretation of Phase Formation in Ta–Mo–Cr–Ti–Al Refractory High‐Entropy Alloys

2025. Advanced Engineering Materials, 27 (24), Art.-Nr.: 2500527. doi:10.1002/adem.202500527 -

Agrawal, S.; Kumar, C.; Avadhani, G. S.; Heilmaier, M.; Suwas, S.

Anisotropic creep and stress rupture behaviour of laser powder bed fusion processed Hastelloy X

2025. Materials Science and Engineering: A, 934, 148342. doi:10.1016/j.msea.2025.148342 -

Ma, W.; Gebauer, J.; Czerny, A. K.; Chegeni, M. R.; Gallino, I.; Busch, R.; Seifert, H. J.

Thermodynamic assessment of the sulfur and the nickel-sulfur systems

2025. Calphad, 89, 102821. doi:10.1016/j.calphad.2025.102821 -

Tang, C.; Schäfer, B.; Schroer, C.; Gorr, B.

Improved oxidation behavior of M–20Cr–20Ta (M: Ni, Fe, Co) ternary alloys by formation of complex Cr–Ta-based oxides

2025. Corrosion Science, 249, Article no: 112847. doi:10.1016/j.corsci.2025.112847 -

Yang, W.; Hasemann, G.; Carrion Saldaña, M.; Gorr, B.; Schwaiger, R.; Krüger, M.

Phase Equilibria in the V-Rich Region of the V-Si-B System at 1400 °C

2025. Journal of Phase Equilibria and Diffusion, 46 (1), 151–169. doi:10.1007/s11669-025-01177-4 -

Pramanik, A.; Konkati, C.; Laube, S.; Yang, L.; Sen, S.; Kauffmann, A.; Heilmaier, M.; Chauhan, A.

Exploring room-temperature deformation mechanisms of a B2-strengthened refractory compositionally complex alloy

2025. Materials Science and Engineering: A, Article no: 148180. doi:10.1016/j.msea.2025.148180 -

Han, S.; Laube, S.; Chen, Z.; Kauffmann, A.; Heilmaier, M.; Inui, H.

Operative slip system and dislocation behavior in a brittle refractory high-entropy alloy with the B2 ordered structure

2025. Journal of Alloys and Compounds, 1020, Article no: 179361. doi:10.1016/j.jallcom.2025.179361 -

Chang, Y.-Y.; Tsai, T.-H.; Chang, C.-E.; Feng, H.-Q.; Yang, M.-X.; Stüber, M.; Ulrich, S.

Mechanical properties and thermal stabilities of multilayered AlCrBN/AlTiSiN hard coatings

2025. Surface and Coatings Technology, 498, Art.-NR.: 131876. doi:10.1016/j.surfcoat.2025.131876 -

Yang, L.; Sen, S.; Schliephake, D.; Vikram, R. J.; Laube, S.; Pramanik, A.; Chauhan, A.; Neumeier, S.; Heilmaier, M.; Kauffmann, A.

Creep behavior of a precipitation-strengthened A2-B2 refractory high entropy alloy

2025. Acta Materialia, 288, Art.-Nr. 120827. doi:10.1016/j.actamat.2025.120827 -

Lee, S.; Do, J.; Choi, B. G.; Bansal, U.; Kirchlechner, C.; Choi, P.-P.; Lee, S.

Local plastic deformation in the vicinity of topologically close-packed phases in a Ni-based single crystal superalloy

2025. Materials & Design, 25, Art.-Nr.: 113600. doi:10.1016/j.matdes.2025.113600 -

Vikram, R. J.; Schliephake, D.; Namadi, M.; Choudhury, A.; Kauffmann, A.; Suwas, S.; Heilmaier, M.

Strategic alloy design and processing for improved mechanical response in the Mo-Si-Ti system

2025. Scripta Materialia, 255, Art.-Nr.: 116341. doi:10.1016/j.scriptamat.2024.116341 -

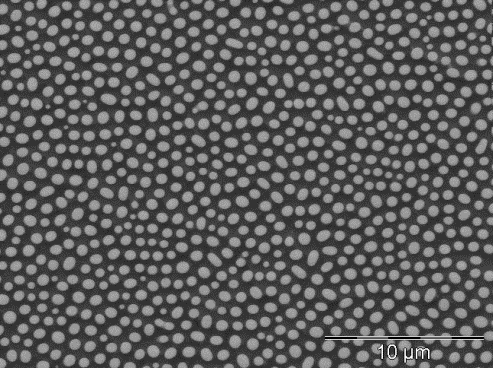

Schäfer, C.; Delfino, P. M.; Leonhard-Trautmann, P.; Ott, V.; Suarez, S.; Stüber, M.; Mücklich, F.; Pauly, C.

Fabrication of Smooth, Periodic Surface Structures: Combining Direct Laser Interference Patterning and Electropolishing

2025. Advanced Engineering Materials, 27 (3), Art.-Nr.: 2400435. doi:10.1002/adem.202400435 -

Ott, V.; Wojcik, T.; Kolozsvari, S.; Polcik, P.; Schäfer, C.; Pauly, C.; Mücklich, F.; Ulrich, S.; Mayrhofer, P. H.; Riedl, H.; Stüber, M.

RuAl Thin‐Film Deposition by DC Magnetron Sputtering

2025. Advanced Engineering Materials, 27 (3). doi:10.1002/adem.202400258

-

Tiedemann, D.; Emmerlich, J.; Herdrich, G.; Müller, M.; Ulrich, S.

Influence of electrode transparency on the plasma properties of a cylindrical IEC plasma source

2024. Vacuum, 230, 113711. doi:10.1016/j.vacuum.2024.113711 -

Lu, K.; Aktaa, J.

Short-term tensile creep behavior of CoCrNi-based multi-principal element alloys

2024. Intermetallics, 175, 108500. doi:10.1016/j.intermet.2024.108500 -

Poulain, R.; Rajkowski, M.; Zhao, Y.; Gemagami, P.; Appolaire, B.; Laube, S.; Kauffmann, A.; Perrière, L.; Couzinié, J.-P.; Li, T.; Laplanche, G.

Oxygen-induced decomposition of the body-centered cubic HfNbTaTiZr high-entropy alloy

2024. Acta Materialia, 280, 120295. doi:10.1016/j.actamat.2024.120295 -

Tang, C.; Dürrschnabel, M.; Jäntsch, U.; Klimenkov, M.; Steinbrück, M.; Ulrich, S.; Hans, M.; Schneider, J. M.; Stüber, M.

Phase formation, structure and properties of quaternary MAX phase thin films in the Cr-V-C-Al system: A combinatorial study

2024. Journal of the European Ceramic Society, 44 (15), Art.-Nr.: 116763. doi:10.1016/j.jeurceramsoc.2024.116763 -

Persdotter, A.; Boll, T.; Ssenteza, V.; Jonsson, T.

Insight into the influence of alloying elements on the secondary corrosion protection of Fe-base alloys by means of atom probe tomography

2024. Corrosion Science, 235, Art.-Nr.: 112175. doi:10.1016/j.corsci.2024.112175 -

Drescher, S.; Seils, S.; Boll, T.; Kauffmann, A.; Heilmaier, M.; Freudenberger, J.

Solid solution strengthening in single-phase Au-Cu-Ni-Pd-Pt-based high-entropy alloys

2024. Journal of Alloys and Compounds, 1002, Artkl.Nr.: 175273. doi:10.1016/j.jallcom.2024.175273 -

Wang, J.; Basu, S.; Kauffmann, A.; Heilmaier, M.; Schwaiger, R.

The effect of grain boundaries and precipitates on the mechanical behavior of the refractory compositionally complex alloy NbMoCrTiAl

2024. Applied Physics Letters, 124 (20), Art.-Nr.: 201905. doi:10.1063/5.0203536 -

Feitosa, A. L. M.; Ribamar, G. G.; Escobar, J.; Sonkusare, R.; Boll, T.; Coury, F.; Ávila, J.; Oliveira, J. P.; Padilha, A. F.

Precipitation and reverted austenite formation in maraging 350 steel: competition or cooperation?

2024. Acta Materialia, 270, 119865. doi:10.1016/j.actamat.2024.119865 -

Yu, C.; Srikanth, S.; Böhlke, T.; Gorr, B.; Maas, U.

Steady laminar stagnation flow NH3-H2-air flame at a plane wall: Flame extinction limit and its influence on the thermo-mechanical stress and corrosive behavior of wall materials

2024. Applications in Energy and Combustion Science, 18, 100261. doi:10.1016/j.jaecs.2024.100261 -

Czerny, A. K.; Ma, W.; Hausner, C. S.; Franke, P.; Rohde, M.; Seifert, H. J.

Thermodynamic assessment of the Mo‐Si system

2024. Advanced Engineering Materials, Artk.Nr.: 230208. doi:10.1002/adem.202302085 -

Schliephake, D.; Thota, H.; Kauffmann, A.; Wu, H.; Pundt, A.; Heilmaier, M.; Eggeler, Y. M.

The Creep‐induced Micro‐ and Nanostructural Evolution of a Eutectic Mo‐Si‐Ti Alloy at 1200 °C

2024. Advanced Engineering Materials, 26 (17), 2301909. doi:10.1002/adem.202301909 -

Fernandez-Martinez, I.; Ganesan, R.; Akhavan, B.; Matthews, D. T. A.; Stueber, M.; Bilek, M. M. M.; McKenzie, D. R.

Room-temperature sputter deposition of gold-colored TiN assisted by niobium bombardment from a bipolar HiPIMS source

2024. Journal of Vacuum Science & Technology A, 42 (2), Art.Nr.: 023107. doi:10.1116/6.0003325 -

Laube, S.; Winkens, G.; Kauffmann, A.; Li, J.; Kirchlechner, C.; Heilmaier, M.

Strength of Disordered and Ordered Al‐containing Refractory High Entropy Alloys

2024. Advanced Engineering Materials, 26 (17), 2301797. doi:10.1002/adem.202301797 -

Pereira, J. N.; Ott, V.; Afonso, C. R. M.; de Sousa Malafaia, A. M.; Stüber, M.; Greiner, C.; Pinto, H. C.

Influence of multilayer nanoarchitecture on phase transformations in the Ti-Cr-Zr system

2024. Surface and Coatings Technology, 477, Art.-Nr.: 130369. doi:10.1016/j.surfcoat.2023.130369 -

Dai, S.; Zhu, J.; Yan, X.; Wu, S.; Liu, Y.; Gao, X.; Fraser, H.; Hodgson, P.; Zhu, Y.; Heilmaier, M.; Huang, A.

Unique Yttria Nanoparticle Strengthening in an Inconel 718 Superalloy Fabricated by Additive Manufacturing

2024. Advanced Materials Technologies, 9 (3), Art.-Nr.: 2301421. doi:10.1002/admt.202301421 -

Beck, K.; Ulrich, A. S.; Czerny, A. K.; White, E. M. H.; Heilmaier, M.; Galetz, M. C.

Aluminide diffusion coatings for improving the pesting behavior of refractory metals

2024. Surface and Coatings Technology, 476, Art.-Nr.: 130205. doi:10.1016/j.surfcoat.2023.130205 -

Kishida, K.; Ito, M.; Inui, H.; Heilmaier, M.; Eggeler, G.

On the inherent strength of Cr23 C6 with the complex face-centered cubic D84 structure

2024. Acta Materialia, 263, Art.-Nr.: 119518. doi:10.1016/j.actamat.2023.119518 -

Daradkeh, S. I.; Recalde, O.; Mousa, M. S.; Sobola, D.; Boll, T.

Oxidation Behavior and Outward Diffusion of Al Along Oxide Grain Boundaries of FeCrAl Alloys Overdoped with Zr and Hf

2024. High Temperature Corrosion of Materials, 101, 41–59. doi:10.1007/s11085-023-10204-z

-

Peng, J.; Huang, W.; Xu, M.; Wang, S.; Xu, Z.; Li, W.; Wang, J.; Wang, C.; Franke, P.; Seifert, H. J.

Thermodynamic modeling of the Al–Cr–Mo–Ni system

2023. AIP Advances, 13 (11), Art.-Nr.: 115022. doi:10.1063/5.0176225 -

Bayoumy, D.; Boll, T.; Karapuzha, A. S.; Wu, X.; Zhu, Y.; Huang, A.

Effective Platform Heating for Laser Powder Bed Fusion of an Al-Mn-Sc-Based Alloy

2023. Materials, 16 (24), Art.-Nr.: 7586. doi:10.3390/ma16247586 -

Burger, L.; Conzelmann, A.; Ulrich, S.; Mozaffari-Jovein, H.

Process Development of a Generative Method for Partial and Controlled Integration of Active Substances into Open-Porous Matrix Structures

2023. Materials, 16 (21), Art.-Nr.: 6985. doi:10.3390/ma16216985 -

Klein, T.; Zhang, D.; Staufer, E.; Boll, T.; Schneider-Broeskamp, C.; Edtmaier, C.; Schmitz-Niederau, M.; Horky, J.; Qiu, D.; Easton, M.

Phase transformation pathways in a Ti-5.9Cu alloy modified with Fe and Al

2023. Journal of Materials Research and Technology, 27, 4978–4985. doi:10.1016/j.jmrt.2023.11.014 -

Galetz, M. C.; Schlereth, C.; White, E. M. H.; Boll, T.; Bik, M.; Sitarz, M.; Chen, W.-T.; Gleeson, B.

An Expanded Model for the Pressure Effect in Metal Dusting of Mn-Containing Alloy 600 Based on Advanced Scale Characterization

2023. High Temperature Corrosion of Materials, 100, 541–555. doi:10.1007/s11085-023-10201-2 -

Wu, J.; Yuan, Y.; Chen, T.; Tang, A.; Wu, L.; Li, D.; Steinbrück, M.; Pan, F.

The oxidation behavior and reaction thermodynamics and kinetics of the Mg-X (X = Ca/Gd/Y) binary alloys

2023. Corrosion Science, 225, Art.-Nr.: 111609. doi:10.1016/j.corsci.2023.111609 -

Litvinov, D.; Lu, K.; Walter, M.; Aktaa, J.

Elemental segregation in CoCrFeMnNi high entropy alloy after intermediate-temperature low cycle fatigue loading

2023. Materials Today Communications, 35, Art.Nr.: 106030. doi:10.1016/j.mtcomm.2023.106030 -

Drescher, S.; Seils, S.; Pohl, D.; Rellinghaus, B.; Kauffmann, A.; Heilmaier, M.; Freudenberger, J.

Softening by spinodal decomposition in Au–Cu–Ni–Pd–Pt high-entropy alloys

2023. Materials Science and Engineering: A, 887, Art.-Nr.: 145772. doi:10.1016/j.msea.2023.145772 -

Charpentier, L.; Kauffmann, A.; Bêche, E.; Escape, C.; Laube, S.; Schliephake, D.; Esvan, J.; Gorr, B.; Soum-Glaude, A.; Heilmaier, M.

Influence of the oxidation on the optical properties of Mo-Si-Ti, Ta-Mo-Cr-Al and Ta-Mo-Cr-Ti-Al alloys

2023. Materials Today Communications, 37, Art.-Nr.: 107056. doi:10.1016/j.mtcomm.2023.107056 -

Fazi, A.; Sattari, M.; Strach, M.; Boll, T.; Stiller, K.; Andrén, H.-O.; Adorno Lopes, D.; Thuvander, M.

CrN–NbN nanolayered coatings for enhanced accident tolerant fuels in BWR

2023. Journal of Nuclear Materials, 586, Art.-Nr.: 154681. doi:10.1016/j.jnucmat.2023.154681 -

Lu, K.; Chauhan, A.; Litvinov, D.; Schneider, M.; Laplanche, G.; Aktaa, J.

Cooperative deformation mechanisms in a fatigued CoCrNi multi-principal element alloy: A case of low stacking fault energy

2023. Journal of the Mechanics and Physics of Solids, 180, Art.-Nr.: 105419. doi:10.1016/j.jmps.2023.105419 -

Li, L.; Chen, Z.; Yuge, K.; Kishida, K.; Inui, H.; Heilmaier, M.; George, E. P.

Plastic deformation of single crystals of the equiatomic Cr-Fe-Co-Ni medium entropy alloy – A comparison with Cr-Mn-Fe-Co-Ni and Cr-Co-Ni alloys

2023. International Journal of Plasticity, 169, Art.-Nr.: 103732. doi:10.1016/j.ijplas.2023.103732 -

Shaji Karapuzha, A.; Fraser, D.; Schliephake, D.; Dietrich, S.; Zhu, Y.; Wu, X.; Huang, A.

Room and elevated temperature tensile and fatigue behaviour of additively manufactured Hastelloy X

2023. Materials Science and Engineering: A, 882, Art.-Nr.: 145479. doi:10.1016/j.msea.2023.145479 -

Yin, B.; Li, L.; Drescher, S.; Seils, S.; Nag, S.; Freudenberger, J.; Curtin, W. A.

Solute misfit and solute interaction effects on strengthening: A case study in AuNi

2023. Acta Materialia, 257, Art.-Nr.: 119118. doi:10.1016/j.actamat.2023.119118 -

Ganesan, R.; Fernandez-Martinez, I.; Akhavan, B.; Matthews, D. T. A.; Sergachev, D.; Stueber, M.; McKenzie, D. R.; Bilek, M. M. M.

Pulse length selection in bipolar HiPIMS for high deposition rate of smooth, hard amorphous carbon films

2023. Surface and Coatings Technology, 454, Art.-Nr.: 129199. doi:10.1016/j.surfcoat.2022.129199 -

Tang, C.; Dürrschnabel, M.; Jäntsch, U.; Klimenkov, M.; Steinbrück, M.; Ulrich, S.; Hans, M.; Schneider, J. M.; Stüber, M.

Synthesis of V

2023. Applied Surface Science, 629, Art.-Nr.: 157340. doi:10.1016/j.apsusc.2023.157340 -

Wang, Z.; Li, L.; Chen, Z.; Yuge, K.; Kishida, K.; Inui, H.; Heilmaier, M.

A new route to achieve high strength and high ductility compositions in Cr-Co-Ni-based medium-entropy alloys: A predictive model connecting theoretical calculations and experimental measurements

2023. Journal of Alloys and Compounds, 959, Artkl.Nr.: 170555. doi:10.1016/j.jallcom.2023.170555 -

Wu, S.; Dai, S. B.; Heilmaier, M.; Peng, H. Z.; Zhang, G. H.; Huang, S.; Zhang, X. J.; Tian, Y.; Zhu, Y. M.; Huang, A. J.

The effect of carbides on the creep performance of Hastelloy X fabricated by laser powder bed fusion

2023. Materials Science and Engineering: A, 875, Arktl.Nr.: 145116. doi:10.1016/j.msea.2023.145116 -

Winkens, G.; Kauffmann, A.; Herrmann, J.; Czerny, A. K.; Obert, S.; Seils, S.; Boll, T.; Baruffi, C.; Rao, Y.; Curtin, W. A.; Schwaiger, R.; Heilmaier, M.

The influence of lattice misfit on screw and edge dislocation-controlled solid solution strengthening in Mo-Ti alloys

2023. Communications Materials, 4 (1), 26. doi:10.1038/s43246-023-00353-8 -

Eusterholz, M. K.; Boll, T.; Ott, V.; Stüber, M.; Lu, Y.; Gebauer, J.; Ulrich, S.; Kauffmann, A.; Heilmaier, M.

Nanoscale oxide formation at α‐Al₂O₃–Nb interfaces

2023. Advanced Engineering Materials, 25 (14), Art.-Nr.: 2201441. doi:10.1002/adem.202201441 -

Kishida, K.; Okutani, M.; Suzuki, H.; Inui, H.; Heilmaier, M.; Raabe, D.

Room-temperature deformation of single crystals of the sigma-phase compound FeCr with the tetragonal D8b structure investigated by micropillar compression

2023. Acta Materialia, 249, Art.-Nr.: 118829. doi:10.1016/j.actamat.2023.118829 -

Taheriniya, S.; Choi, N.; Yang, S.; Sonkusare, R.; Yu, J. H.; Lee, J.-S.; Rösner, H.; Peterlechner, M.; Boll, T.; Gammer, C.; Hahn, H.; Divinski, S. V.; Wilde, G.

Additively manufactured equiatomic CoCrFeMnNi high entropy alloy: Precipitation-induced heterogeneity by mechano-chemical coupling

2023. Journal of Alloys and Compounds, 938, Article no: 168514. doi:10.1016/j.jallcom.2022.168514 -

Kuczyńska-Zemła, D.; Kwaśniak, P.; Sotniczuk, A.; Boll, T.; Chassaing, D.; Bazarnik, P.; Wieciński, P.; Pisarek, M.; Ostrowski, R.; Garbacz, H.

Effect of interference laser treatment on the surface region homogeneity of a biomedical β -Ti alloy

2023. Applied Surface Science, 614, Art.-Nr.: : 156211. doi:10.1016/j.apsusc.2022.156211 -

Schellert, S.; Weber, M.; Christ, H. J.; Wiktor, C.; Butz, B.; Galetz, M. C.; Laube, S.; Kauffmann, A.; Heilmaier, M.; Gorr, B.

Formation of rutile (Cr,Ta,Ti)O₂ oxides during oxidation of refractory high entropy alloys in Ta-Mo-Cr-Ti-Al system

2023. Corrosion Science, 211, Art.Nr. 110885. doi:10.1016/j.corsci.2022.110885 -

Beinert, A. J.; Romer, P.; Heinrich, M.; Aktaa, J.; Neuhaus, H.

Thermomechanical design rules for photovoltaic modules

2023. Progress in Photovoltaics: Research and Applications, 31 (12), 1181–1193. doi:10.1002/pip.3624

-

Schreiber, D. K.; Schwaiger, R.; Heilmaier, M.; McCormack, S. J.

Materials properties characterization in the most extreme environments

2022. MRS Bulletin, 47 (11), 1128–1142. doi:10.1557/s43577-022-00441-z -

Yoo, B.; Jung, C.; Ryou, K.; Choi, W. S.; Haußmann, L.; Yang, S.; Boll, T.; Neumeier, S.; Choi, P.-P.

Directed energy deposition of γ/γ’ Co-Al-W superalloys

2022. Additive Manufacturing, 60 (Part B), Art.-Nr.: 103287. doi:10.1016/j.addma.2022.103287 -

Laube, S.; Kauffmann, A.; Schellert, S.; Seils, S.; Tirunilai, A. S.; Greiner, C.; Eggeler, Y. M.; Gorr, B.; Christ, H.-J.; Heilmaier, M.

Formation and thermal stability of two-phase microstructures in Al-containing refractory compositionally complex alloys

2022. Science and Technology of Advanced Materials, 23 (1), 692–706. doi:10.1080/14686996.2022.2132118 -

Leyland, A.; Rebholz, C.; Schneider, J. M.; Stüber, M.; Yerokhin, A.

Plasma-based Surface Engineering: Celebrating the research career of Professor Allan Matthews, FREng : Preface

2022. Surface and Coatings Technology, 442, Art.-Nr.: 128593. doi:10.1016/j.surfcoat.2022.128593 -

Tirunilai, A. S.; Hinrichs, F.; Schliephake, D.; Engstler, M.; Mücklich, F.; Obert, S.; Winkens, G.; Kauffmann, A.; Heilmaier, M.

Phase continuity, brittle to ductile transition temperature and creep behavior of a eutectic Mo‐20Si‐52.8Ti alloy

2022. Advanced Engineering Materials, 24 (11), Art.Nr. 2200918. doi:10.1002/adem.202200918 -

Chen, Z.; Kishida, K.; Inui, H.; Heilmaier, M.; Glatzel, U.; Eggeler, G.

Improving the intermediate- and high-temperature strength of L1

2022. Acta Materialia, 238, Art.-Nr.: 118224. doi:10.1016/j.actamat.2022.118224 -

Hofmann, P.; Gryga, R.; Müller, M.; Stüber, M.; Ulrich, S.

Multiscale simulation of hollow cathode assisted internal plasma treatment process

2022. Surface and Coatings Technology, 442, Art.Nr. 128422. doi:10.1016/j.surfcoat.2022.128422 -

Sonkusare, R.; Biswas, K.; Gan, W.; Brokmeier, H. G.; Gurao, N. P.

Texture Evolution During Hot Compression of CoCuFeMnNi Complex Concentrated Alloy Using Neutron Diffraction and Crystal Plasticity Simulations

2022. Transactions of the Indian Institute of Metals, 75, 3061–3066. doi:10.1007/s12666-022-02689-0 -

Lu, K.; Knöpfle, F.; Chauhan, A.; Litvinov, D.; Schneider, M.; Laplanche, G.; Aktaa, J.

Elevated-temperature cyclic deformation mechanisms of CoCrNi in comparison to CoCrFeMnNi

2022. Scripta Materialia, 220, Art.-Nr.: 114926. doi:10.1016/j.scriptamat.2022.114926 -

Hinrichs, F.; Kauffmann, A.; Tirunilai, A. S.; Schliephake, D.; Beichert, B.; Winkens, G.; Beck, K.; Ulrich, A. S.; Galetz, M. C.; Long, Z.; Thota, H.; Eggeler, Y.; Pundt, A.; Heilmaier, M.

A novel nitridation- and pesting-resistant Cr-Si-Mo alloy

2022. Corrosion Science, 207, Art.-Nr.: 110566. doi:10.1016/j.corsci.2022.110566 -

Gebauer, J.; Franke, P.; Seifert, H. J.

Thermodynamic Evaluation of the system Ta–O and Preliminary Assessment of the Systems Al–Nb–O and Al–Ta–O

2022. Advanced Engineering Materials, 24 (8), Art.-Nr. 2200162. doi:10.1002/adem.202200162 -

Wei, S.; Liu, J.; Xia, Y.; Zhang, H.; Cheng, R.; Sun, L.; Xu, F.; Huang, P.; Rosei, F.; Pimerzin, A. A.; Seifert, H. J.; Pan, H.

Remarkable catalysis of spinel ferrite XFe2O4 (X = Ni, Co, Mn, Cu, Zn) nanoparticles on the dehydrogenation properties of LiAlH4: An experimental and theoretical study

2022. Journal of Materials Science & Technology, 111, 189–203. doi:10.1016/j.jmst.2021.08.088 -

Lu, K.; Knöpfle, F.; Chauhan, A.; Jeong, H. T.; Litvinov, D.; Walter, M.; Kim, W. J.; Aktaa, J.

Low-cycle fatigue behavior and deformation mechanisms of a dual-phase Al

2022. International Journal of Fatigue, 163, Art.-Nr.: 107075. doi:10.1016/j.ijfatigue.2022.107075 -

Wojcik, T.; Ott, V.; Özbilen, S.; Leiste, H.; Ulrich, S.; Mayrhofer, P. H.; Riedl, H.; Stueber, M.

Magnetron sputtered NiAl/TiB

2022. Journal of Vacuum Science & Technology A, 40 (3), Art.-Nr.: 033410. doi:10.1116/6.0001734 -

Lu, K.; Chauhan, A.; Litvinov, D.; Aktaa, J.

Temperature-dependent cyclic deformation behavior of CoCrFeMnNi high-entropy alloy

2022. International Journal of Fatigue, 160, Art.Nr. 106863. doi:10.1016/j.ijfatigue.2022.106863 -

Lu, K.; Chauhan, A.; Knöpfle, F.; Aktaa, J.

Effective and back stresses evolution upon cycling a high-entropy alloy

2022. Materials Research Letters, 10 (6), 369–376. doi:10.1080/21663831.2022.2054667 -

Anton, R.; Hüning, S.; Laska, N.; Weber, M.; Schellert, S.; Gorr, B.; Christ, H.-J.; Heilmaier, M.; Schulz, U.

Interface reactions of magnetron sputtered Si-based dual layer coating systems as oxidation protection for Mo-Si-Ti alloys

2022. Surface and Coatings Technology, 444, 128620. doi:10.1016/j.surfcoat.2022.128620 -

Sahu, V. K.; Sonkusare, R.; Biswas, K.; Gurao, N. P.

In Situ Experiments: Paving Ways for Rapid Development of Structural Metallic Materials for a Sustainable Future

2022. Journal of the Indian Institute of Science, 102, 173–210. doi:10.1007/s41745-022-00292-2 -

Kishida, K.; Chen, Z.; Matsunoshita, H.; Maruyama, T.; Fukuyama, T.; Sasai, Y.; Inui, H.; Heilmaier, M.

Plastic deformation of bulk and micropillar single crystals of Mo₅Si₃ with the tetragonal D8

2022. International Journal of Plasticity, 155, Art.-Nr. 103339. doi:10.1016/j.ijplas.2022.103339 -

Fonseca, E. B.; Escobar, J. D.; Gabriel, A. H. G.; Ribamar, G. G.; Boll, T.; Lopes, É. S. N.

Tempering of an additively manufactured microsegregated hot-work tool steel: A high-temperature synchrotron X-ray diffraction study

2022. Additive Manufacturing, 55, Art.Nr. 102812. doi:10.1016/j.addma.2022.102812 -

Eusterholz, M. K.; Boll, T.; Gebauer, J.; Weidner, A.; Kauffmann, A.; Franke, P.; Seifert, H.-J.; Biermann, H.; Aneziris, C.; Heilmaier, M.

High‐temperature ternary oxide phases in Ta/Nb‐Alumina composite materials

2022. Advanced Engineering Materials, 24 (8), Art.-Nr.: 2200161. doi:10.1002/adem.202200161 -

Schneider, J.; Ulrich, S.; Patscheider, J.; Stueber, M.

Wear Study of a Magnetron-Sputtered TiC/a-C Nanocomposite Coating under Media-Lubricated Oscillating Sliding Conditions

2022. Coatings, 12 (4), Art.-Nr.: 446. doi:10.3390/coatings12040446 -

Schulz, C.; Kauffmann, A.; Laube, S.; Kellner, M.; Nestler, B.; Heilmaier, M.

Role of orientation relationship for the formation of morphology and preferred orientation in NiAl-(Cr,Mo) during directional solidification

2022. Acta Materialia, 231, Art.Nr. 117857. doi:10.1016/j.actamat.2022.117857 -

Ivanisenko, Y.; Mazilkin, A.; Gallino, I.; Riegler, S. S.; Doyle, S.; Kilmametov, A.; Fabrichnaya, O.; Heilmaier, M.

On the formation of nanocrystalline aluminides during high pressure torsion of Al/Ni alternating foils and post-processing multilayer reaction

2022. Journal of alloys and compounds, 905, Art. Nr.: 164201. doi:10.1016/j.jallcom.2022.164201 -

Wicht, D.; Kauffmann, A.; Schneider, M.; Heilmaier, M.; Böhlke, T.

On the impact of the mesostructure on the creep response of cellular NiAl-Mo eutectics

2022. Acta materialia, 226, Art.-Nr. 117626. doi:10.1016/j.actamat.2022.117626 -

Wu, J.; Yuan, Y.; Yang, L.; Chen, T.; Li, D.; Wu, L.; Jiang, B.; Steinbrück, M.; Pan, F.

The oxidation behavior of Mg-Er binary alloys at 500 ℃

2022. Corrosion Science, 195, Art.-Nr.: 109961. doi:10.1016/j.corsci.2021.109961 -

Bayoumy, D.; Kwak, K.; Boll, T.; Dietrich, S.; Schliephake, D.; Huang, J.; Yi, J.; Takashima, K.; Wu, X.; Zhu, Y.; Huang, A.

Origin of non-uniform plasticity in a high-strength Al-Mn-Sc based alloy produced by laser powder bed fusion

2022. Journal of materials science & technology, 103, 121–133. doi:10.1016/j.jmst.2021.06.042 -

Lu, K.; Chauhan, A.; Litvinov, D.; Tirunilai, A. S.; Freudenberger, J.; Kauffmann, A.; Heilmaier, M.; Aktaa, J.

Micro-mechanical deformation behavior of CoCrFeMnNi high-entropy alloy

2022. Journal of materials science & technology, 100, 237–245. doi:10.1016/j.jmst.2021.04.079

-

Tang, C.; Shi, H.; Jianu, A.; Weisenburger, A.; Victor, G.; Grosse, M.; Müller, G.; Seifert, H. J.; Steinbrück, M.

High-temperature oxidation of AlCrFeNi-(Mn or Co) high-entropy alloys: Effect of atmosphere and reactive element addition

2021. Corrosion science, 192, Art.Nr.: 109809. doi:10.1016/j.corsci.2021.109809 -

Anton, R.; Hüning, S.; Laska, N.; Weber, M.; Schellert, S.; Gorr, B.; Christ, H.-J.; Schulz, U.

Graded PVD Mo-Si interlayer between Si coating and Mo-Si-B alloys: Investigation of oxidation behaviour

2021. Corrosion Science, 192, Art.-Nr.: 109843. doi:10.1016/j.corsci.2021.109843 -

Persdotter, A.; Boll, T.; Jonsson, T.

Minor element effect on high temperature corrosion of a low-alloyed steel: Insight into alkali- and chlorine induced corrosion by means of atom probe tomography

2021. Corrosion Science, 192, Art.-Nr.: 109779. doi:10.1016/j.corsci.2021.109779 -

Chen, T.; Mo, L.; Yuan, Y.; Liu, J.; Wang, J.; Li, D.; Jiang, B.; Pan, F.

Investigation on the Phase Relationship and Solidification Processes of Mg-rich Mg-Mn-Y Alloys

2021. Journal of phase equilibria and diffusion, 42 (4), 441–451. doi:10.1007/s11669-021-00908-7 -

Tiedemann, D.; Hofmann, P.; Emmerlich, J.; Chan, Y.-A.; Ulrich, S.; Herdrich, G.; Müller, M.

Cylindrical inertial electrostatic confinement plasma source for surface treatment

2021. Vacuum, 193, Art.-Nr.: 110502. doi:10.1016/j.vacuum.2021.110502 -

Schellert, S.; Gorr, B.; Laube, S.; Kauffmann, A.; Heilmaier, M.; Christ, H. J.

Oxidation mechanism of refractory high entropy alloys Ta-Mo-Cr-Ti-Al with varying Ta content

2021. Corrosion science, 192, Article no: 109861. doi:10.1016/j.corsci.2021.109861 -

Engel, B.; Ohneseit, S.; Mäde, L.; Beck, T.

Influence of Grain Orientation Distribution on the High Temperature Fatigue Behaviour of Notched Specimen Made of Polycrystalline Nickel-Base Superalloy

2021. Metals, 11 (5), 731. doi:10.3390/met11050731 -

Laube, S.; Schellert, S.; Srinivasan Tirunilai, A.; Schliephake, D.; Gorr, B.; Christ, H.-J.; Kauffmann, A.; Heilmaier, M.

Microstructure tailoring of Al-containing compositionally complex alloys by controlling the sequence of precipitation and ordering

2021. Acta Materialia, 218, Article no: 117217. doi:10.1016/j.actamat.2021.117217 -

Klumpp, A.; Kauffmann, A.; Seils, S.; Dietrich, S.; Schulze, V.

Influence of Cold Rotary Swaging on Microstructure and Uniaxial Mechanical Behavior in Alloy 718

2021. Metallurgical and materials transactions / A, 52, 4331–4341. doi:10.1007/s11661-021-06371-w -

Schellert, S.; Gorr, B.; Christ, H.-J.; Pritzel, C.; Laube, S.; Kauffmann, A.; Heilmaier, M.

The Effect of Al on the Formation of a CrTaO₄ Layer in Refractory High Entropy Alloys Ta-Mo-Cr-Ti-xAl

2021. Oxidation of metals, 96, 333–345. doi:10.1007/s11085-021-10046-7 -

Lu, K.; Chauhan, A.; Tirunilai, A. S.; Freudenberger, J.; Kauffmann, A.; Heilmaier, M.; Aktaa, J.

Deformation mechanisms of CoCrFeMnNi high-entropy alloy under low-cycle-fatigue loading

2021. Acta materialia, 215, Art.-Nr.: 117089. doi:10.1016/j.actamat.2021.117089 -

Perepezko, J. H.; Krüger, M.; Heilmaier, M.

Mo-Silicide Alloys for High-Temperature Structural Applications

2021. Materials Performance and Characterization, 10 (2), Article: 20200183. doi:10.1520/MPC20200183 -

Singh Negi, A.; Sourav, A.; Heilmaier, M.; Biswas, S.; Thangaraju, S.

Quantitative Phase Prediction in Dual-Phase High-Entropy Alloys: Computationally Aided Parametric Approach

2021. Physica Status Solidi (B) Basic Research, 258 (6), Art. Nr.: 2100106. doi:10.1002/pssb.202100106 -

Hatakeyama, T.; Kauffmann, A.; Obert, S.; Gombola, C.; Heilmaier, M.; Yoshimi, K.

Oxidation Resistance, Creep Strength and Room-Temperature Fracture Toughness of Mo–28Ti–14Si–6C–6B Alloy

2021. Materialia, 16, Art.Nr. 101108. doi:10.1016/j.mtla.2021.101108 -

Boll, T.; Babic, V.; Panas, I.; Bäcke, O.; Stiller, K.

On aliovalent cations control of α-alumina growth on doped and undoped NiAl

2021. Acta Materialia, 210, Art.-Nr.: 116809. doi:10.1016/j.actamat.2021.116809 -

Yang, L.; Yuan, Y.; Chen, T.; Dai, X.; Zhang, L.; Li, D.; Tang, A.; Yi, W.; Zhang, L.; Pan, F.

Diffusion behaviour and mechanical properties of binary Mg–Gd system

2021. Intermetallics, 133, Art.-Nr.: 107171. doi:10.1016/j.intermet.2021.107171 -

Gabel, S.; Giese, S.; Merle, B.; Sprenger, I.; Heilmaier, M.; Neumeier, S.; Bitzek, E.; Göken, M.

Microcantilever Fracture Tests on Eutectic NiAl‐Cr(Mo) in‐situ Composites

2021. Advanced engineering materials, 23 (6), Art.-Nr. 202001464. doi:10.1002/adem.202001464 -

Gorr, B.; Schellert, S.; Müller, F.; Christ, H.-J.; Kauffmann, A.; Heilmaier, M.

Current Status of Research on the Oxidation Behavior of Refractory High Entropy Alloys

2021. Advanced engineering materials, 23 (5), Art.-Nr.: 2001047. doi:10.1002/adem.202001047 -

Chen, T.; Yuan, Y.; Liu, T.; Li, D.; Tang, A.; Chen, X.; Schmid-Fetzer, R.; Pan, F.

Effect of Mn Addition on Melt Purification and Fe Tolerance in Mg Alloys

2021. JOM, 73, 892–902. doi:10.1007/s11837-020-04550-5 -

Wu, J.; Yuan, Y.; Yu, X.; Chen, T.; Li, D.; Wu, L.; Jiang, B.; Atrens, A.; Pan, F.

The high-temperature oxidation resistance properties of magnesium alloys alloyed with Gd and Ca

2021. Journal of materials science, 49, 8745–8761. doi:10.1007/s10853-020-05758-1 -

Chen, H.; Hanemann, T.; Seils, S.; Schliephake, D.; Tirunilai, A. S.; Heilmaier, M.; Weiss, K.-P.; Kauffmann, A.

Influence of Temperature and Plastic Strain on Deformation Mechanisms and Kink Band Formation in Homogenized HfNbTaTiZr

2021. Crystals, 11 (2), 81. doi:10.3390/cryst11020081 -

Obert, S.; Kauffmann, A.; Pretzler, R.; Schliephake, D.; Hinrichs, F.; Heilmaier, M.

The Creep and Oxidation Behaviour of Pesting-Resistant

2021. Metals, 11 (1), Art.-Nr.: 169. doi:10.3390/met11010169 -

Borzone, G.; Delsante, S.; Li, D.; Novakovic, R.

New Insights into Phase Equilibria of the Sb-Sn System

2021. Journal of phase equilibria and diffusion, 42, 63–76. doi:10.1007/s11669-020-00849-7 -

Lu, K.; Chauhan, A.; Walter, M.; Tirunilai, A. S.; Schneider, M.; Laplanche, G.; Freudenberger, J.; Kauffmann, A.; Heilmaier, M.; Aktaa, J.

Superior low-cycle fatigue properties of CoCrNi compared to CoCrFeMnNi

2021. Scripta materialia, 194, Art.-Nr.: 113667. doi:10.1016/j.scriptamat.2020.113667 -

Greß, T.; Glück Nardi, V.; Schmid, S.; Hoyer, J.; Rizaiev, Y.; Boll, T.; Seils, S.; Tonn, B.; Volk, W.

Vertical continuous compound casting of copper aluminum bilayer rods

2021. Journal of materials processing technology, 288, Art.-Nr.: 116854. doi:10.1016/j.jmatprotec.2020.116854

-

Wang, J.; Yuan, Y.; Cheng, X.; Chen, T.; Jiang, B.; Li, D.; Tang, A.; Boll, T.; Pan, F.

The High-Solution Design of Magnesium Alloys

2021. Magnesium Technology 2021. Ed.: V. M. Miller, 27–31, Springer. doi:10.1007/978-3-030-65528-0_5