Power-based Fuels and Chemicals

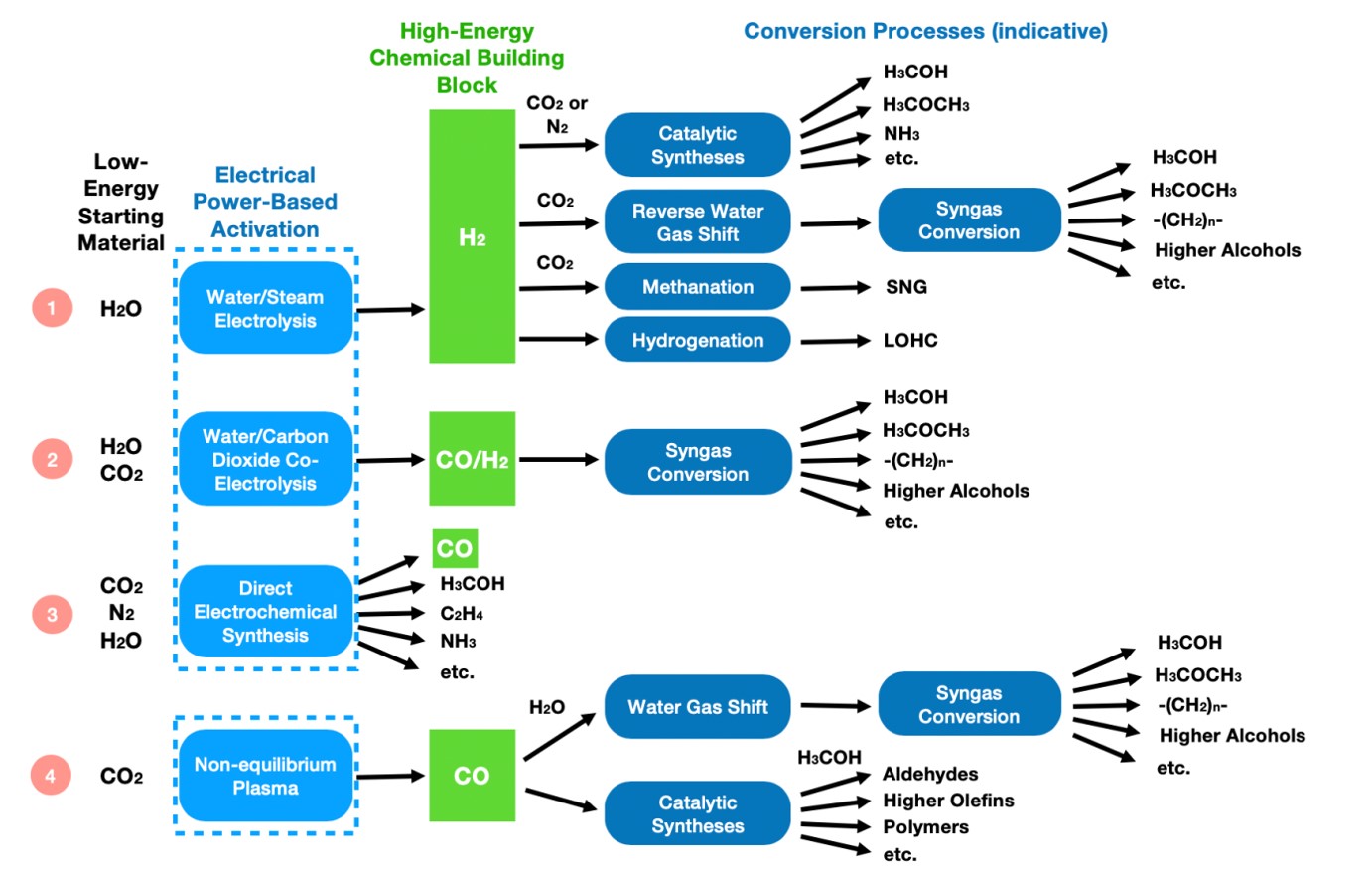

The subtopic addresses the conversion of the low-energy molecules CO2, H2O and N2 with renewable electrical energy as well as renewable or waste heat into high-energy chemical fuels and feedstocks for industry. This way the subtopic will contribute to a defossilization of the transport sector and the industrial sector. The CO2 may originate from different sources which are jointly evaluated together with researchers from Topic 5. Given the desired reduction of the anthropogenic CO2 emissions, thin air or waste biomass are preferred choices. However, CO2 from unavoidable industrial sources such as cement production, steel making, and waste incineration is considered as well. We strive for advancing the scientific knowledge in catalysis, electrocatalysis and plasma chemistry both with a view to activation of CO2, H2O and N2 and efficient catalytic processes for synthesis of high-quality fuels and chemicals from its products. The scope includes high-temperature mixed ionic-electronic conductor (MIEC)-based ceramic membrane reactors, which hold potential for improving various conversion steps. Catalytic technologies for the loading and unloading of liquid organic hydrogen carriers (LOHCs) and a direct use of hydrogenated LOHCs in fuel cells are in focus as well. High-performing catalysts and electrocatalysts showing high activity and selectivity and long lifetime even under dynamic load are targeted. Similarly, highly permeable and stable membranes are pursued.

Simple, efficient and reliable process technologies, capable of dynamic operation will be developed, scaled-up, and demonstrated on system level in real technical environments together with key partners from industry and society. Special emphasis is on intensified process technologies with modular design. Disruptive approaches to the fabrication of compact process units will be taken, e.g. additive manufacturing, to achieve high performance, reliability in operation, and cost-effective digitized fabrication. The scope includes the design and study of entire power-to-molecules process chains with vast integration of material and heat flows between process units to achieve a high overall energy efficiency. Both solutions for large-scale implementation and compact systems for decentralized applications will be pursued where operational flexibility is needed in addition to high efficiency and acceptable cost. The subtopic strives for rapid implementation of modular power-to-molecules technologies with high technology readiness level (TRL) by teaming up with innovative industrial partners. Two spin-off companies INERATEC GmbH (KIT) and Hydrogenious Technologies GmbH (University of Erlangen-Nürnberg) as well as other visionary start-up’s and their allies are key partners for commercialization. At the same time, high-risk approaches at lower TRLs with high potential gain will be fundamentally investigated and purposefully further developed.

Sitemap

sprungmarken_marker_650

Generic paths for synthesis of fuels & chemicals

Main themes are...

- Modular integrated plants

- Conversion of CO/CO2-rich syngas

- Direct electrochemical synthesis (Electocatalysis beyond hydrogen)

- Plasma reactors / Plasma activation of inert molecules

- H2-Safety of decentralized modular plants

- Technologies for LOHC - Liquid organic hydrogen carriers

We work in the above six thematic groups. This enables scientific exchange and joint cooperation across institutes and Helmholtz centers. To strengthen networking between the Helmholtz partners, joint workshops are held regularly.

Selected Projects | Project Archive

We engage in collaborative research projects with academic & industrial partners. Thus, we transfer knowledge into application, strengthen networking & talent management.

Electroorganic synthesis - from research to industry: IAM-ET: Joint pool of electrode materials and electrolysis cells (Pool Mazel); IMVT: Development and analysis of a large-scale electrolyzer for long-term operation (EAGLE); BMBF website, KIT-news

https://zukunftscluster-etos.de/

UP-TO-ME is an EU funded project that targets a ground-breaking change in decentralised Power-to-Methanol production for hard to electrify applications, like marine vessels. Grant number: 101083323

https://up-to-me.com/

Synthesis of model catalysts and operando characterization methods. Basic energy research (BMBF) Grant: 03SF0673B; Partner: KIT IKFT, HZB, FH IKTS, Sasol Germany, INERATEC, KIT IIP, R&D Center FH Kiel

Care-O-SENE website3D printing laboratory & Fischer Tropsch synthesis plant

115 students, doctoral candidates and scientists met at KIT on June 12 and 13, 2024 to discuss progress and scientific challenges of our Helmholtz research program.

More...

What are the processes & technologies to produce chemicals without fossil sources but with renewable energies? Sharing progress and scientific challenges in our research program.

Read more

Assessing the role of Direct Air Capture in a carbon neutral world: The workshop shall establish a basic understanding of the major DAC technologies and their differences...

Helmholtz-Workshop: July 2, 2021

aims to present the scope of research in our different groups, share both knowledge & experiences and initiate opportunities for networking & co-operation between Helmholtz Centers.

Transfer of Knowledge and Technology

We share and transfer knowledge and technology to the public, experts, politics, administration and the business world.

KIT`s startup ICODOS uses an innovative Power-to-X technology to produce green methanol. ICODOS, KIT, and BASF launch world’s first fully-integrated, automated and dynamically operated e-methanol plant.

https://icodos.com/

Modular chemical plants for Gas-to-Liquid, Power-to-Gas & Power-to-Liquid processes producing CO2 neutral fuels for mobility, storage of "green" energy & decentralized production of chemicals: INERATEC

INERATEC GmbH

Workshop of industry, science & policy makers about innovative products & technical solutions reducing energy consumption & CO2 emissions.

EE4InG website

We offer girls from 8th grade onwards exciting insights into our work & labs: Fuels from air & green energy @IMVT, H2 a sustainable energy storage @ITCP/IKFT, Battery empty?! @BTC

more@Girls' Day Radar

The objective of the project is to identify key innovations of energy-efficient solutions and to network them in their different application areas within the BMWi Research Network Energy.

EE4InG website

7 May 2021: Nanocat's role & potentials for CO2 savings & energy efficiency was discussed in the workshop of the Research Network Energy with stakeholders of the innovation system: academia, industry, associations, and policymakers.

Publications

-

Vermaak, V.; Cunningham, R. D.; Potgieter, J. H.; Botha, J. M.; van Steen, E.; Claeys, M.; Fadlalla, M.; Hoffman, J.-A.; Abdullah, S.; Sireci, E.; Studt, F.; Zimina, A.; Grunwaldt, J.-D.; Hsu, C.; Wolf, M.; Jiménez, C.; Sakoglu, P.; Moodley, D.

Manganese-enhanced Cobalt Catalysts for Fischer-Tropsch Synthesis: A review of structural and electronic promotion effects

2026. Catalysis Science & Technology. doi:10.1039/D5CY01467K -

Maurer, L.; Warmuth, L.; Thiele, M.; Guse, D.; Kind, M.; Wasserscheid, P.; Pitter, S.; Wolf, M.; Auer, F.

Improved Copper‐Zinc Based Catalysts for the Partial Dehydrogenation of Dicyclohexylmethanol

2026. ChemCatChem, 18 (2). doi:10.1002/cctc.202501689 -

Warmuth, L.; Hofsäß, C.; Zevaco, T. A.; Schild, D.; Pitter, S.; Sauer, J.

Investigation of methanol catalyst stability in presence of potential green hydrogen impurities

2026. International Journal of Hydrogen Energy, 207, 153382. doi:10.1016/j.ijhydene.2026.153382 -

Zhang, Q.; Zhang, T.; Liu, B.; Fedorova, E.; Doronkin, D. E.; Kondratenko, E. V.

SSZ‐13 Zeolite with Isolated Co

2026. Angewandte Chemie International Edition, Art.-Nr.: e19600. doi:10.1002/anie.202519600 -

Zhang, Q.; Zhang, T.; Liu, B.; Fedorova, E.; Doronkin, D. E.; Kondratenko, E. V.

SSZ‐13‐Zeolith mit Isolierten Co

2026. Angewandte Chemie, Art.-Nr.: e19600. doi:10.1002/ange.202519600 -

Groppe, P.; Zimmermann, T.; Madubuko, N.; Bürner, K.; Sheng, Y.; Wichmann, C.; Moritz, M. S.; Czechowsky, J.; Müller, V.; Libuda, J.; Wasserscheid, P.; Mandel, K.; Daeneke, T.; Grunwaldt, J.-D.; Papp, C.; Haumann, M.; Retzer, T.; Taccardi, N.; Wintzheimer, S.

The influence of GaPt droplet purification on the catalytic performance of supraparticles as supported catalytically active liquid metal solutions (SCALMS) in propane dehydrogenation

2026. Journal of Materials Chemistry A. doi:10.1039/D5TA08306K -

Strugovshchikov, E.; Medrano-Banda, A.; Bouillet, C.; Sun, J.; Badets, V.; Papaefthimiou, V.; Isaiev, M.; Röse, P.; Savinova, E. R.; Oshchepkov, A. G.

Tailoring selectivity of electrocatalytic glucose oxidation on (Ni)Au catalysts through the surface state control

2026. Electrochimica Acta, 548, 147877. doi:10.1016/j.electacta.2025.147877 -

Kardeş, G.; Röse, P.; Wildersinn, L.; Jeschull, F.; Korneychuk, S.; Pundt, A.; Grunwaldt, J.-D.; Krewer, U.

Understanding the Influence of Iridium Oxide Catalyst State on the Performance in Oxygen Evolution Reaction

2026. ACS Catalysis, 16 (1), 211–227. doi:10.1021/acscatal.5c03350 -

Monning, M.; Asadli, A.; Bajohr, S.; Wolf, M.; Kolb, T.

Determination of reaction kinetics in three phase CO 2 methanation

2026. Reaction Chemistry & Engineering, Art.-Nr.: d5re00337g. doi:10.1039/D5RE00337G -

Pashminehazar, R.; Fam, Y.; Diaz, A.; Holler, M.; Kronenberg, M.; Ihli, johannes; Grunwaldt, J.-D.; Sheppard, T. L.

Hard X-ray nanotomography reveals anomalous and expected thermal coarsening behaviour of nanoporous gold

2026. Nanoscale Advances, 8 (2), 662–672. doi:10.1039/D5NA00561B -

Dalpke, S.; Yang, J.; Forooghi, P.; Frohnapfel, B.; Stroh, A.

Data-driven correlations for thermohydraulic roughness properties

2026. European Journal of Mechanics - B/Fluids, 115, Art.-Nr.: 204355. doi:10.1016/j.euromechflu.2025.204355 -

Schulte, M. L.; Truttmann, V.; Baumgarten, L.; Nicolai, A. G.; Montalvo Beltran, D. A.; Summ, F. J.; Kiener, C.; Saraçi, E.; Grunwaldt, J.-D.

Spectroscopic Reactor for Operando Investigations Made by Additive Manufacturing for High‐Pressure Catalysis Applications

2026. Chemistry–Methods, 6 (1). doi:10.1002/cmtd.202500105 -

Guci, M.; Knäbbeler-Buß, M.; Verkama, E.; Günthel, M.; Islam, M. R.; Kienle, L.; Saraçi, E.; Grunwaldt, J.-D.; Nestler, F.

NH

2026. Applied Catalysis A: General, 709, 120616. doi:10.1016/j.apcata.2025.120616 -

Almeida De Campos, L.; Ciocci, P.; Schröder, J.; Sheppard, T. L.

Advanced Characterization of Proton Exchange Membrane Water Electrolyzers with Spatially‐Resolved X‐Ray Imaging

2026. ChemCatChem, 18 (1), Art.-Nr.: e00530. doi:10.1002/cctc.202500530 -

Seitz, M.; Kannengießer, M. P.; Stelzner, B.; Hagen, F. P.; Braun, L.; Kaltenbach, J.; Märkle, K.; Peterlechner, M.; Spielmann, J.; Doronkin, D. E.; Deutschmann, M. P.; Grunwaldt, J.-D.; Eggeler, Y. M.; Kramm, U. I.; Nirschl, H.; Trimis, D.

Reduction of micron-sized iron oxide particles with high initial porosity in a fluidized bed reactor using hydrogen: Morphology and phase analysis

2026. Fuel, 405, Art.-Nr.: 136422. doi:10.1016/j.fuel.2025.136422

-

Sireci, E.; Sharapa, D. I.; Studt, F.

A Comprehensive Overview of Active Sites of fcc-Co Nanoparticles and Their Role in CO Splitting─A DFT Study

2025. The Journal of Physical Chemistry C, 129 (49), 21634–21641. doi:10.1021/acs.jpcc.5c07278 -

Vicente, H.; Huber, P.; Gayubo, A. G.; Studt, F.; Plessow, P. N.

Reactivity of Pentamethylcyclopentenyl Cations toward Olefin Formation in the Methanol-to-Olefin (MTO) Process

2025. The Journal of Physical Chemistry C, 129 (47), 20971–20980. doi:10.1021/acs.jpcc.5c07265 -

Paksoy, A. I.; Bobadilla, L. F.; Blay-Roger, R.; Merkouri, L.-P.; López-Flores, V.; Coppex, C.; Jelic, J.; Studt, F.; Ramirez Reina, T.; Odriozola, J. A.; Duyar, M. S.

Evidence of ambient pressure methanol production on Ni-Ga-Ca dual function materials and dynamic restructuring effects on selectivity

2025. Chemical Engineering Journal, 520, 164122. doi:10.1016/j.cej.2025.164122 -

Huang, G.; Wu, Y.; Li, Y.; Du, S.; Liu, Q.; Li, M.; Zhang, D.; Jiang, Z.; Zhong, S.; Lu, S.; Tao, L.; Wang, S.

Lattice Hydrogen Boosts CO Tolerance of Pd Anode Catalysts in High‐Temperature Proton Exchange Membrane Fuel Cells

2025. Advanced Functional Materials, 35 (12). doi:10.1002/adfm.202415358 -

Yu, X.; Rabiee, H.; Dutta, A.; Li, Y.; Szakály, Z.; Vesztergom, S.; Warmuth, L.; Rieder, A.; Broekmann, P.

Upcycling CO

2025. Journal of the American Chemical Society, 147 (45), 41481–41491. doi:10.1021/jacs.5c11708 -

Ghule, S.; Korenkov, K. O.; Sharapa, D. I.; Amsharov, K. Y.; Kataev, E. A.; Oshchepkov, A. S.

Naphthalimide‐Buckybowl Tweezer for Selective Recognition of Fullerene C

2025. Chemistry – A European Journal, 31 (24). doi:10.1002/chem.202500773 -

Huynh, T.-N.; Thi Minh Nguyet, N.; Ai, B. D.; Trung, N. T.

Tetrel, nonconventional hydrogen bonds, and noticeable role of dispersion in complexes of fluoroform and carbon dichalcogenides

2025. Physical Chemistry Chemical Physics, 27 (28), 14966–14975. doi:10.1039/d5cp01508a -

Rui, S.; Xiao, J.; Wang, C.; Wang, F.; Kuznetsov, M.; Jordan, T.

Numerical study on the influence of vent burst pressure on vented hydrogen explosions using a turbulent combustion model

2025. Process Safety and Environmental Protection, 201, 107431. doi:10.1016/j.psep.2025.107431 -

Davari, S.; Chacko, R.; Bastek, T.; Lott, P.; Dailly, J.; Angeli, S.; Deutschmann, O.

Experimental and microkinetic investigation of thermo-catalytic ammonia decomposition over a Ba-promoted Ru/Ni-BCZY catalyst for use in ammonia-fed protonic ceramic cells

2025. Applied Catalysis A: General, 708, 120571. doi:10.1016/j.apcata.2025.120571 -

Lim, A.; Ham, K.; Quast, T.; Lee, S.; Tesch, M. F.; Czioska, S.; Ramermann, D.; Hetaba, W.; Schuhmann, W.; Grunwaldt, J.-D.; Cho, S. K.; Park, H.-Y.; Jang, J. H.; Ahn, S. H.; Spanos, I.; Park, H. S.

Limited Surface Oxide Growth as a Prerequisite for Stabilizing Low-Loading Iridium Electrodes for PEM Water Electrolysis

2025. ACS Catalysis, 15 (8), 6098–6113. doi:10.1021/acscatal.4c07864 -

Costamagna, P.; Sanna, C.; Holtappels, P.; Artini, C.; Pani, M.

Impact of the Oxygen Vacancies of the LSCF (La

2025. ChemElectroChem, 12 (20), 1–10. doi:10.1002/celc.202500165 -

Kalinina, E. A.; Kalinin, M. A.; Sharapa, D. I.; Maid, H.; Freidzon, A.; Haeri, H. H.; Hinderberger, D.; Dinnebier, R.; Oshchepkov, A. S.; Amsharov, K. Y.

The Mystery of Dibenzoterrylene: a Clar‐interlocked Biphenalenyl Biradical

2025. Chemistry – A European Journal, 31 (71), Art.-Nr.: e02952. doi:10.1002/chem.202502952 -

Rüde, T.; Strauch, D.; Szesni, N.; Wolf, M.; Wasserscheid, P.; Auer, F.

Catalyst shape matters: Influence of catalyst shape on reactor performance in hydrogen release from perhydro benzyltoluene

2025. International Journal of Hydrogen Energy, 191, 152174. doi:10.1016/j.ijhydene.2025.152174 -

Dent, F. J.; Dreisbach, M.; Kriegseis, J.; Stroh, A.; Yabu, H.; Khodaparast, S.

Opportunities for Multiscale Pattern Modulation with Temporally Arrested Breath Figures

2025. Advanced Materials Interfaces, Art.-Nr.: e00811. doi:10.1002/admi.202500811 -

Weber, D.; Engl, T.; Raabe, M.; Hutzler, A.; Rubin, M.; Dittmeyer, R.; Franken, T.

Revealing the characteristics of supported Ni-Mn based mixed metal oxide catalysts: Operando insights into their activation and

2025. Applied Catalysis A: General, 708, Art.-Nr. 120582. doi:10.1016/j.apcata.2025.120582 -

Zhong, S.; Sui, P.; Holtappels, P.; Navarrete, A.; Li, F.; Dittmeyer, R.

Corrigendum to “Robust and efficient electroreduction of CO

2025. Chemical Engineering Journal, 514, Art.-Nr.: 163103. doi:10.1016/j.cej.2025.163103 -

Elwalily, A.; Verkama, E.; Mantei, F.; Kaliyeva, A.; Pounder, A.; Sauer, J.; Nestler, F.

Sustainable aviation fuel production via the methanol pathway: a technical review

2025. Sustainable Energy & Fuels, 9 (19), 5151–5180. doi:10.1039/d5se00231a -

Freund, H.; Sauer, J.; Ehrhardt, K.

Elektrifizierung der chemischen Industrie: Eine spannende Herausforderung entlang Skalen und Prozessketten

2025. Chemie Ingenieur Technik, 97 (5), 363 – 363. doi:10.1002/cite.202500048 -

Pan, X.; Chen, Y.; Lu, L.; Wang, Z.; Hua, M.; Xiao, J.; Jiang, J.

Research on the flow characteristics and spontaneous ignition mechanism of high-pressure hydrogen in semi-closed T-tube

2025. International Journal of Hydrogen Energy, 145, 991–1006. doi:10.1016/j.ijhydene.2025.06.046 -

Warmuth, L.; Zevaco, T. A.; Guse, D.; Zimmermann, M.; Kind, M.; Pitter, S.

Phase Transformation Processes in Coprecipitated Cu/Zn/Zr Methanol Catalyst Precursors—Insights into Suspension Aging Form Ultrafast Nucleation

2025. ChemPlusChem, 90 (9), e202500284. doi:10.1002/cplu.202500284 -

Wörner, M.

Dispersion and residence time distribution of laminar tubular flow in the transition regime – models for flow chemistry and beyond

2025. Chemical Engineering Science, 318, 122116. doi:10.1016/j.ces.2025.122116 -

Ba, Q.; Xiao, J.; Yao, C.; Li, X.; Cheng, X.; Xie, B.; Gao, M.; Jordan, T.

Numerical study and machine learning prediction for high-pressure hydrogen jet flames

2025. Process Safety and Environmental Protection, 203, Art.-Nr. 107961. doi:10.1016/j.psep.2025.107961 -

Huang, J.; Klahn, M.; Bartling, S.; Zimina, A. V.; Rockstroh, N.; Steinfeldt, N.; Peppel, T.; Grunwaldt, J.-D.; Strunk, J.

Atomically Dispersed Palladium Promoted Suzuki–Miyaura Cross Coupling

2025. ChemSusChem, 18 (20), e202500953. doi:10.1002/cssc.202500953 -

Plessow, P. N.

Anharmonic Adsorption Free Energies and Apparent Activation Barriers for Mobile Reactants Based on Molecular Dynamics Simulations

2025. Journal of Chemical Theory and Computation, 21 (17), 8518–8532. doi:10.1021/acs.jctc.5c01100 -

Sireci, E.; Grüger, T. D.; Plessow, P. N.; Sharapa, D. I.; Studt, F.

Modeling the shape and stability of supported Co nanoparticles under Fischer–Tropsch conditions via DFT calculations and Monte Carlo simulations: insights into CO-driven surface reconstruction

2025. Catalysis Science & Technology, 15 (22), 6703–6715. doi:10.1039/d5cy00921a -

Zhang, F.; Wang, H.; Zhang, E.; Tischer, S.; Deutschmann, O.; Sui, R.

Kinetic Insights into Ammonia Decomposition over Rhodium: A Combined Experimental, Modeling, and Theoretical Study

2025. The Journal of Physical Chemistry C, 129 (40), 17955–17965. doi:10.1021/acs.jpcc.5c04975 -

Huynh, T.-N.; Mounssef, B., Jr.; Sharapa, D. I.; Studt, F.; Bučko, T.

Anharmonic Correction to the Adsorption Free Energy of Oxygen-Containing Intermediates on Pt(111) by Machine-Learned Force Field-Based Thermodynamic Integrations

2025. The Journal of Physical Chemistry C, 129 (37), 16742–16755. doi:10.1021/acs.jpcc.5c03465 -

Lacerda de Oliveira Campos, B.; Beeskow, P.; Drexler, M.; Herrera Delgado, K.; Arnold, U.; Sauer, J.

Kinetic modeling and conceptual design of the OME synthesis from trioxane and dimethyl ether on H-ZSM-5

2025. Chemical Engineering Science, 312, Art.-Nr.: 121655. doi:10.1016/j.ces.2025.121655 -

Enss, A. E.; Plessow, P. N.; Studt, F.

A computational study on the formation mechanism of naphthalenic species under MTO conditions in H-SSZ-13

2025. Catalysis Science & Technology, 15 (23), 7200–7208. doi:10.1039/d5cy00837a -

Jägerfeld, P. J.; Gossler, H.; Riedel, J.; Angeli, S.; Wang, Y.; Bernart, S.; Jelic, J.; Studt, F.; Deutschmann, O.

A Combined Infrared Spectroscopy Database and Analysis Tool

2025. Chemie Ingenieur Technik, 97 (5), 463–471. doi:10.1002/cite.202400150 -

Paripsa, S.; Gaur, A.; Lützenkirchen-Hecht, D.

Investigating crystallisation kinetics of Fe

2025. Journal of Alloys and Compounds, 1043, 184136. doi:10.1016/j.jallcom.2025.184136 -

Elwalily, A.; Verkama, E.; Mantei, F.; Kaliyeva, A.; Pounder, A.; Sauer, J.; Nestler, F.

Correction: Sustainable aviation fuel production via the methanol pathway: a technical review

2025. Sustainable Energy & Fuels, 9 (19), 5386–5386. doi:10.1039/d5se90062j -

Liu, N.; Pham, T. M.; Han, Y.; Yang, L.; Bokareva, O. S.; Bartling, S.; Springer, A.; Spannenberg, A.; Kubis, C.; Weiss, J.; Doronkin, D. E.; Ju, W.; Francke, R.

Heterogenized Copper(II) Phenanthroline Catalysts for Electroreduction of CO2 to C2 Compounds: Substitution on the Ligand Causes Structural Changes to the Molecular Framework and Stability Enhancement

2025. Advanced Materials, Art.-Nr.: e13702. doi:10.1002/adma.202513702 -

Kaya, M.; Ferchow, J.; Meboldt, M.; Klahn, C.

Machine learning-assisted design automation workflow of non-uniform flow distributors for multipass crossflow device

2025. Results in Engineering, 27, Art.-Nr. 106931. doi:10.1016/j.rineng.2025.106931 -

Barthelmeß, A.; Wambo Tchatchou, A. J.; Zimmermann, M.; Trouillet, V.; Wolf, M.

Activity Boost for Cobalt–Selectivity Shift and Activation During CO 2 Methanation by Carbon Nitride‐Modified Al 2 O 3 Support

2025. ChemCatChem, e00506. doi:10.1002/cctc.202500506 -

Gietzelt, T.; Walter, M.; Toth, V.; Messerschmidt, F.; Blem, M.

Investigation of Oxide Dispersion Strengthening Effect on the Strength of Diffusion‐Bonded AISI304 Parts

2025. Advanced Engineering Materials, 27 (21), Art.-Nr.: 2500616. doi:10.1002/adem.202500616 -

Röse, P.

Trendbericht Technische Chemie 2025

2025. Nachrichten aus der Chemie, 73 (6), 50–58. doi:10.1002/nadc.20254149203 -

Lausch, M.; Ruan, Y.; Brockmann, P.; Zimina, A.; Etzold, B. J. M.; Hussong, J.

Influence of light, temperature, and iron oxidation state on the dissolution rate of combusted iron particles in oxalic acid

2025. Results in Engineering, 27, 105851. doi:10.1016/j.rineng.2025.105851 -

Savintseva, L.; Neugebauer, P.; Sharapa, D. I.; Röse, P.; Krewer, U.; Studt, F.

The Electrochemical Shono Oxidation of N‐Formylpyrrolidine: Mechanistic Insights from the Computational Ferrocene Electrode Model and Cyclic Voltammetry

2025. ChemElectroChem, 12 (19), Art.-Nr. e202500202. doi:10.1002/celc.202500202 -

Rui, S.; Xiao, J.; Wang, F.; Kuznetsov, M.; Jordan, T.

Numerical study of maximum overpressure in vented hydrogen explosions

2025. Process Safety and Environmental Protection, 200, 107387. doi:10.1016/j.psep.2025.107387 -

Amelung, L.; Barty, A.; Murphy, B. M.; Grunwaldt, J.-D.; Hövelmann, S.; Leonau, A.; Paripsa, S.; Schneidewind, A.; Busch, S.; Gutt, C.; Lohstroh, W.; Schreiber, F.; Unruh, T.

DAPHNE4NFDI - Improving Research data management at Synchrotron Facilities

2025. Journal of Physics: Conference Series, 3010 (1), 012133. doi:10.1088/1742-6596/3010/1/012133 -

Paripsa, S.; Gaur, A.; Förste, F.; Doronkin, D. E.; Malzer, W.; Schlesiger, C.; Kanngießer, B.; Welter, E.; Grunwaldt, J.-D.; Lützenkirchen-Hecht, D.

RefXAS : an open access database of X-ray absorption spectra – improvements and outlook

2025. Journal of Physics: Conference Series, 3010 (1), 012124. doi:10.1088/1742-6596/3010/1/012124 -

Yang, J.; Stroh, A.; Bagheri, S.; Frohnapfel, B.; Forooghi, P.

Characterization of hydrodynamic and thermal properties of anisotropic irregular roughness

2025. International Journal of Heat and Fluid Flow, 116, 109888. doi:10.1016/j.ijheatfluidflow.2025.109888 -

Zhang, Q.; Kondratenko, V. A.; Ding, X.; Weiss, J.; Bartling, S.; Fedorova, E.; Zhao, D.; Doronkin, D. E.; Wang, D.; Kubis, C.; Kondratenko, E. V.

Understanding the reaction-induced restructuring of CoOₓ species in silicalite-1 to control selectivity in non-oxidative dehydrogenation of propane

2025. Chinese Journal of Catalysis, 74, 108–119. doi:10.1016/S1872-2067(25)64724-3 -

Biffar, L.; Brinker, N. M.; Pfeifer, P.; Dittmeyer, R.; Grunwaldt, J.-D.; Doronkin, D. E.

Structure–Activity Relationships in RuCs/MgO Catalysts During Ammonia Synthesis

2025. ChemSusChem, 18 (19), Art.-Nr.: 2501035. doi:10.1002/cssc.202501035 -

Heß, D.; Rubin, M.; Dittmeyer, R.

A Novel Approach to Electrochemical Direct Air Capture Using Aqueous l -Arginine Amino Acid Solutions as an Absorption Solvent: Proof-of-Concept and Technoeconomics

2025. Industrial & Engineering Chemistry Research, 64 (30), 14973–14985. doi:10.1021/acs.iecr.4c04844 -

Sireci, E.; Grüger, T. D.; Plessow, P. N.; Sharapa, D. I.; Studt, F.

Modeling the Shape and Stability of Co Nanoparticles as a Function of Size and Support Interactions through DFT Calculations and Monte Carlo Simulations

2025. The Journal of Physical Chemistry C, 129 (29), 13232–13243. doi:10.1021/acs.jpcc.5c02777 -

Dorner, I.; Osiewacz, J.; Röse, P.; Ellendorff, B.; Röhe, M.; Turek, T.; Krewer, U.

Control of electrolyte intrusion in carbon-free silver gas diffusion electrodes for electrochemical CO2 reduction

2025. Journal of CO$_2$ Utilization, 99, Art.-Nr.: 103163. doi:10.1016/j.jcou.2025.103163 -

Witzel, R.; Wildersinn, L.; Tusini, E.; Czioska, S.; Dorner, I.; Zimina, A.; Grunwaldt, J.-D.; Röse, P.

Investigation of the performance and stability of copper and brass nanoparticles for CO₂ reduction in organic electrolytes

2025. Journal of CO2 Utilization, 97, Article no: 103138. doi:10.1016/j.jcou.2025.103138 -

Dreisbach, M.; Hinojos, I.; Kriegseis, J.; Stroh, A.; Burgmann, S.

Interface reconstruction of adhering droplets for distortion correction using color-coded glare points and deep learning

2025. International Journal of Multiphase Flow, 191, 105288. doi:10.1016/j.ijmultiphaseflow.2025.105288 -

Wolf, M.; Gradl, T.; Raseale, S.; Maliugin, A.; Raman, N.; Schühle, P.; Taccardi, N.; Claeys, M.; Sharapa, D. I.; Studt, F.; Fischer, N.; Haumann, M.; Wasserscheid, P.

In‐Pt Supported Catalytically Active Liquid Metal Solutions for Propane Dehydrogenation – Role of Surface Acidity of Support

2025. ChemCatChem, 17 (12), e202402096. doi:10.1002/cctc.202402096 -

Etzold, B. J. M.; Hungsberg, M.; Ebrahim-Moghaddam, M.; Herold, F.; Dahmen, N.; Studt, F.

Energy Requirements for Sustainable Olefin Production From CO₂ via Electro‐ or Thermal Catalysis

2025. Chemical Engineering & Technology, 48 (6). doi:10.1002/ceat.70034 -

Yang, Q.; Fedorova, E. A.; Cao, D.-B.; Saraçi, E.; Kondratenko, V. A.; Kreyenschulte, C. R.; Lund, H.; Bartling, S.; Weiß, J.; Doronkin, D. E.; Grunwaldt, J.-D.; Brückner, A.; Jiao, H.; Kondratenko, E. V.

Understanding Mn-modulated restructuring of Fe-based catalysts for controlling selectivity in CO2 hydrogenation to olefins

2025. Nature Catalysis, 8 (6), 595–606. doi:10.1038/s41929-025-01334-5 -

Abarca, J. A.; Warmuth, L.; Rieder, A.; Dutta, A.; Vesztergom, S.; Broekmann, P.; Irabien, A.; Díaz-Sainz, G.

GDE Stability in CO

2025. ACS Catalysis, 15, 8753–8767. doi:10.1021/acscatal.5c02052 -

Schiaroli, A.; Claussner, L.; Campari, A.; Cirrone, D.; Linseisen, B.; Friedrich, A.; Torres de Ritter, E. L.; Kuznetsov, M.; Ustolin, F.

A comprehensive review on liquid hydrogen transfer operations and safety considerations for mobile applications

2025. International Journal of Hydrogen Energy, 107, 164–182. doi:10.1016/j.ijhydene.2024.12.266 -

Wu, K.; Kondratenko, V. A.; Zhou, M.; Doronkin, D.; Bartling, S.; Zhang, Q.; Han, S.; Jia, X.; Liu, Q.; Xiong, D.; Xu, C.; Jiang, G.; Zhao, D.; Rodemerck, U.; Linke, D.; Kondratenko, E. V.

The Role of Reducibility of PtGaO x ‐based Catalysts for Efficient and Durable Propane Dehydrogenation

2025. Angewandte Chemie International Edition. doi:10.1002/anie.202506704 -

Koch, R.; Dittmeyer, R.

Comparative analysis of industrialization potentials of direct air capture technologies

2025. Frontiers in Climate, 7, Art.-Nr.: 1558396. doi:10.3389/fclim.2025.1558396 -

Chacko, R.; Keller, K.; Shirsath, A. B.; Angeli, S.; Lott, P.; Deutschmann, O.

Microkinetic Modeling of Support Effects in PdO-Based Methane Oxidation Catalysts

2025. ACS Catalysis, 15 (9), 6937 – 6952. doi:10.1021/acscatal.5c00516 -

Wen, Y.; Zormpa, F.; Sharapa, D. I.; Studt, F.; Raffelt, K.; Dahmen, N.

Exploring the hydrodeoxygenation of lignin β-O-4 dimer model compound and bio-oil by DFT and experimental studies

2025. Molecular Catalysis, 580, 115134. doi:10.1016/j.mcat.2025.115134 -

Zormpa, F.; Treu, P.; Saraçi, E.

Advancing biomass valorization with zeolite catalysts: Focus on oxidative transformations

2025. Sustainable Chemistry for the Environment, 10, 100249. doi:10.1016/j.scenv.2025.100249 -

Zhong, S.; Yang, W.; Liu, S.; Dittmeyer, R.

Synergistic electroreduction of CO

2025. International Journal of Hydrogen Energy, 119, 73–81. doi:10.1016/j.ijhydene.2025.03.234 -

Vajglová, Z.; Mäki-Arvela, P.; Yevdokimova, O.; Martinez-Klimov, M.; Simakova, I.; Eränen, K.; Tirri, T.; van Hoeven, J. E. S.; Peuronen, A.; Huš, M.; Likozar, B.; Lastusaari, M.; Lindén, J.; Doronkin, D. E.; Murzin, D. Y.

Effect of catalyst support on dihydroeugenol hydrodeoxygenation on low cost FeNi catalyst to produce renewable alkane fuel

2025. Applied Catalysis A: General, 701, Aricle no: 120307. doi:10.1016/j.apcata.2025.120307 -

Ioannidou, G.; Drexler, M.; Arnold, U.; Sauer, J.; Lemonidou, A. A.

One step erythritol hydrodeoxygenation towards green butadiene over mixed molybdenum-rhenium supported catalysts

2025. Applied Catalysis A: General, 698, 120234. doi:10.1016/j.apcata.2025.120234 -

Drexler, M.; Zaghini Francesconi, V.; Arnold, U.; Zevaco, T. A.; Sauer, J.

Production of oxymethylene ethers (OME) as sustainable diesel fuel substitutes: continuous synthesis from dimethyl ether and trioxane and evaluation of catalyst stability

2025. RSC Sustainability, 3 (4), 1941–1956. doi:10.1039/D4SU00818A -

Chowdhury, C.; Studt, F.; Jelic, J.

Metal–Support Interactions in Metal/Oxide and Inverse Oxide/Metal Catalysts: A Case Study Using Cu/ZnO and ZnO/Cu Model Catalysts

2025. The Journal of Physical Chemistry C, 129 (12), 5860–5867. doi:10.1021/acs.jpcc.4c08821 -

Niethammer, B.; Zormpa, F.; Hoang, G. T.; Slaby, N. A.; Zevaco, T. A.; Karakoulia, S.; Arnold, U.; Sauer, J.

Conversion of dimethyl ether to hydrocarbons catalyzed by Pd-loaded *MRE zeolites

2025. Catalysis Today, 453, 115258. doi:10.1016/j.cattod.2025.115258 -

Rui, S.; Xiao, J.; Wang, C.; Wang, F.; Kuznetsov, M.; Jordan, T.

Numerical study of the effect of obstacles on vented hydrogen explosions

2025. International Journal of Hydrogen Energy, 111, 183–195. doi:10.1016/j.ijhydene.2025.02.340 -

Lu, J.; Hong, R.; Zhang, Y.; Zhong, Y.; Link, G.; Wengenmayer, L. H.; Li, J.; Li, N.

Continuous carbon fiber reinforced filaments manufactured by a cost-effective and two-step impregnation approach

2025. Procedia CIRP, 132, 98–103. doi:10.1016/j.procir.2025.01.017 -

Fedorova, E. A.; Fedorov, A.; Doronkin, D. E.; Linke, D.; Kubis, C.; Brückner, A.; Kondratenko, E. V.

Revealing the Mechanism and Kinetics of Fe 5 C 2 Formation From Ferrous Oxalate under CO 2 Fischer‐Tropsch Conditions Using Time‐Resolved In Situ X‐Ray Absorption Spectroscopy

2025. Chemistry–Methods, 5 (5). doi:10.1002/cmtd.202400058 -

Treu, P.; Iltsiou, D.; Elbuga-Ilica, R.; Maliakkal, C.; Kegnæs, S.; Saraçi, E.

Enhancing the oxidative cleavage of vicinal diols on Fe-ZSM-5 catalysts with hierarchical porosity

2025. Sustainable Chemistry for the Environment, Article no: 100232. doi:10.1016/j.scenv.2025.100232 -

George, G.; Sharapa, D. I.; Stasyuk, A. J.; Poater, A.; Solà, M.; Posada-Pérez, S.

Surface engineering for enhanced perovskite solar cells: Fullerene-mediated trap state formation on CsPbI3 (001) surface

2025. Solar Energy Materials and Solar Cells, 283, 113441. doi:10.1016/j.solmat.2025.113441 -

Wang, B.; Yu, Z.; Chen, S.; Da Roit, N.; Schild, D.; Zimmermann, M.; Wang, Y.; Behrens, S.

Single‐Step Synthesis of Dimethyl Ether from Syngas over Nanoparticle‐Derived Bifunctional Pd/CeO2/Al2O3 Catalysts

2025. Angewandte Chemie International Edition, 64 (16), Art.-Nr.: e202423273. doi:10.1002/anie.202423273 -

Lazaar, N.; Wu, S.; Qin, S.; Hamrouni, A.; Bikash Sarma, B.; Doronkin, D. E.; Denisov, N.; Lachheb, H.; Schmuki, P.

Single‐Atom Catalysts on C₃N₄ : Minimizing Single Atom Pt Loading for Maximized Photocatalytic Hydrogen Production Efficiency

2025. Angewandte Chemie International Edition, 64 (6), e202416453. doi:10.1002/anie.202416453 -

Fu, H.; Luan, J.; Yang, L.; Luan, Y.; Magagnato, F.; Stroh, A.

Experimental and numerical study on the effect mechanism of geometric parameters on jet impingement cooling in a limited space

2025. International Journal of Thermal Sciences, 207, 109384. doi:10.1016/j.ijthermalsci.2024.109384 -

Herrmann, D.; Hodapp, P.; Starman, M.; Huang, P.-C.; Lin, C.-L.; Le, L. B. Q.; Fischer, T. G.; Bizzarri, C.; Röse, P.; Oppel, N.; Klar, J.; Tremouilhac, P.; Holzhauer, L.; Herres-Pawlis, S.; Hoffmann, A.; Seitz, T.; Dorn, A.; Zeitler, K.; Jung, N.; Bräse, S.

Enhancing FAIRdata by providing digital workflows from data generation to the publication of data: an open source approach described for cyclic voltammetry

2025. Chemical Science, 16 (10), 4430–4441. doi:10.1039/d4sc08620a -

Jeyalakshmi, V.; Wu, S.; Qin, S.; Zhou, X.; Sarma, B. B.; Doronkin, D. E.; Kolařík, J.; Šoóš, M.; Schmuki, P.

Pd single atoms on g-C 3 N 4 photocatalysts: minimum loading for maximum activity

2025. Chemical Science, 16 (11), 4788–4795. doi:10.1039/D4SC08589B -

Sakas, G.; Rentschler, P.; Kosonen, A.; Holtappels, P.; Ruuskanen, V.; Kauranen, P.; Ahola, J.; Dittmeyer, R.

Dynamic mass and energy balance model of a 50 kW proton exchange membrane electrolyzer system

2025. Applied Energy, 382, 125199. doi:10.1016/j.apenergy.2024.125199 -

Li, Q.; Zhou, G.; Pan, C.; Xu, Z.; Wang, C.

Mach reflections of a cellular detonation on a split wedge

2025. Combustion and Flame, 273, 113962. doi:10.1016/j.combustflame.2024.113962 -

Zaghini Francesconi, V.; Drexler, M.; Zevaco, T. A.; Arnold, U.; Sauer, J.

Modified Oxymethylene Ethers Based on Technical Alcohol Mixtures and their Fuel Properties

2025. Chemie Ingenieur Technik, 97 (5), 495–507. doi:10.1002/cite.202400159 -

Schulte, M. L.; Truttmann, V.; Doronkin, D. E.; Baumgarten, L.; Nicolai, A.; Beltran, D. A. M.; Summ, F. J.; Kiener, C.; Warmuth, L.; Pitter, S.; Saraçi, E.; Grunwaldt, J.-D.

Monitoring the Fate of Zn in the Cu/ZnO/ZrO

2025. Angewandte Chemie International Edition, 64 (15). doi:10.1002/anie.202423281 -

Makhmutov, D.; Fedorova, E.; Zanina, A.; Kubis, C.; Zhao, D.; Doronkin, D.; Rockstroh, N.; Bartling, S.; Armbruster, U.; Wohlrab, S.; Kondratenko, E. V.

Reaction Pathways of Methanol Formation in CO 2 Hydrogenation over Pd-Based Catalysts

2025. ACS Catalysis, (15), 2328–2341. doi:10.1021/acscatal.4c07462 -

Camacho Hernandez, J. N.; Link, G.

Innovative Approaches on the Estimation of the Effective Permittivity of Fibrous Media

2025. Materials, 18 (1), 14. doi:10.3390/ma18010014 -

Warmuth, L.; Zevaco, T. A.; Pitter, S.

In situ FT-IR reveals ageing phenomena in the formation of a Cu/Zn/Zr methanol catalyst precursor

2025. Inorganic Chemistry Communications, 172, Art.-Nr.: 113753. doi:10.1016/j.inoche.2024.113753 -

Mahayni, Y.; Maurer, L.; Baumeister, I.; Auer, F.; Wasserscheid, P.; Wolf, M.

Batch and continuous synthesis of well‐defined Pt/Al2O3 catalysts for the dehydrogenation of homocyclic LOHCs

2025. ChemCatChem, 17 (6), Art.-Nr.: e202401762. doi:10.1002/cctc.202401762 -

Grinschek, F.; Betz, J.; Chiu, C.-M.; Dübal, S.; Klahn, C.; Dittmeyer, R.

Additive manufactured helical micro distillation units for modular small-scale plants

2025. Chemical Engineering and Processing - Process Intensification, 208, 110113. doi:10.1016/j.cep.2024.110113 -

Korneychuk, S.; Wagner, S.; Rohleder, D.; Vana, P.; Pundt, A.

Local Hydrogen Concentration and Distribution in Pd Nanoparticles: An In Situ STEM‐EELS Approach

2025. Small, Art.-Nr.: 2407092. doi:10.1002/smll.202407092 -

Fuchs, C.; Arnold, U.; Sauer, J.

Synthesis of sustainable aviation fuels via (co–)oligomerization of light olefins

2025. Fuel, 382, 133680. doi:10.1016/j.fuel.2024.133680 -

Neyyathala, A.; Fako, E.; De, S.; Gashnikova, D.; Maurer, F.; Grunwaldt, J.-D.; Schunk, S. A.; Hanf, S.

From Poison to Promotor: Spatially Isolated Metal Sites in Supported Rhodium Sulfides as Hydroformylation Catalysts

2025. Small Structures, 6 (1), 2400260. doi:10.1002/sstr.202400260 -

Rago, V.; Fernandes, T.; Mohr, M.

Identifying Key Training Load and Intensity Indicators in Ice Hockey Using Unsupervised Machine Learning

2025. Research Quarterly for Exercise and Sport, 96 (1), 21–33. doi:10.1080/02701367.2024.2360162 -

Schulte, M. L.; Sender, V. C.; Baumgarten, L.; Beck, A.; Nilayam, A. R. L.; Saraçi, E.; Grunwaldt, J.-D.

Tuning Flame Spray Pyrolysis for Variation of the Crystallite Size in Cu/ZnO/ZrO

2025. European Journal of Inorganic Chemistry, 28 (4), e202400684. doi:10.1002/ejic.202400684 -

Korneychuk, S.; Grosselindemann, C.; Menzler, N. H.; Weber, A.; Pundt, A.

In-situ TEM reduction of a solid oxide cell with NiO/YSZ fuel electrode

2025. Journal of Power Sources, 625, 235626. doi:10.1016/j.jpowsour.2024.235626 -

Shirsath, A. B.; Mokashi, M.; Pashminehazar, R.; Çelik, A.; Lott, P.; Tischer, S.; Grunwaldt, J.-D.; Deutschmann, O.

Investigating the formation of soot in CH4 pyrolysis reactor: A numerical, experimental, and characterization study

2025. Carbon, 231, Art.-Nr.: 119689. doi:10.1016/j.carbon.2024.119689 -

Chedevergne, F.; Yang, J.; Stroh, A.; Forooghi, P.

Analysis of Separation in the Roughness Sublayer Using DNS Data and DANS/DEM Modelling of Roughness Effects

2025. Flow, Turbulence and Combustion, 114 (3), 713–735. doi:10.1007/s10494-024-00585-9

-

Lu, Z.; Shao, M.; Burger, B.; Liu, S.; Klahn, C.; Ruiter, N. V.

Chirp-Like Excitation for Pulse Compression in LED-Based Photoacoustic Imaging

2025. 2025 IEEE International Ultrasonics Symposium (IUS), Utrecht, 15th-18th September 2025, 1–3, Institute of Electrical and Electronics Engineers (IEEE). doi:10.1109/IUS62464.2025.11201254 -

Arnold, U.; Drexler, M.; Fuchs, C.; Niethammer, B.; Sauer, J.

Production of Fuels from Renewables via Methanol

2025. Proceedings of the 2nd Cognitive Mobility Conference. Ed.: P. Baranyi, 218–227, Springer Nature Switzerland. doi:10.1007/978-3-031-87620-2_21 -

Grune, J.; Sempert, K.; Banuti, D. T.

Experimental Investigation of Stable Performance in a H2/air RDC for Hydrogen-Based Power Generation

2025. AIAA SCITECH 2025 Forum, Orlando, 6th-10th January 2025, American Institute of Aeronautics and Astronautics. doi:10.2514/6.2025-1775

-

Wu, Z.; Cheng, Q.; Gu, X.; Wang, Z.; Lu, L.; Pan, X.; Hua, M.; Xiao, J.; Jiang, J.

Experimental investigation on the development characteristics of high-pressure hydrogen jet flame under different ignition conditions

2024. International Journal of Hydrogen Energy, 79, 791–801. doi:10.1016/j.ijhydene.2024.07.053 -

Fu, H.; Luan, J.; Yang, L.; Luan, Y.; Magagnato, F.; Stroh, A.

Multi-objective optimization of jet impingement cooling structure with smooth target surface and enhanced target surface in a limited space

2024. International Communications in Heat and Mass Transfer, 159, 108192. doi:10.1016/j.icheatmasstransfer.2024.108192 -

Saini, S.; Halldin Stenlid, J.; Deo, S.; Plessow, P. N.; Abild-Pedersen, F.

A First-Principles Approach to Modeling Surface Site Stabilities on Multimetallic Catalysts

2024. ACS Catalysis, 14 (2), 874–885. doi:10.1021/acscatal.3c04337 -

Virt, M.; Zaghini Francesconi, V.; Drexler, M.; Arnold, U.; Sauer, J.; Zöldy, M.

An Artificial Intelligence Approach to Predict Physical Properties of Liquid Hydrocarbons

2024. Periodica Polytechnica Chemical Engineering, 68 (4), 561 – 570. doi:10.3311/PPch.38160 -

Shi, J.; Zhang, H.; Xiao, J.; Wen, J.; Usmani, A. S.

Numerical investigation of the effect of riser spacing on gas explosion from semi-submersible platform

2024. Process Safety and Environmental Protection, 188, 239–250. doi:10.1016/j.psep.2024.05.117 -

Lausch, M.; Zimina, A.; Bao, J.; Pashminehazar, R.; Etzold, B. J. M.; Kramm, U. I.; Grunwaldt, J.-D.; Hussong, J.

New insights into the dissolution mechanisms of iron oxides and combusted iron particles in oxalic acid

2024. The Journal of Chemical Physics, 161 (19), 194308. doi:10.1063/5.0229410 -

Jordt, P.; Osterhoff, M.; Tymoshenko, Y.; Hakim, B.; Dolcet, P.; Maurer, F.; Biniyaminov, V.; Amelung, L.; Dall’Antonia, F.; Grunwaldt, J.-D.; Weber, F.; Lohstroh, W.; Murphy, B. M.

Specifications for Electronic Laboratory Notebooks (ELN) in the Photon and Neutron Community

2024. Synchrotron Radiation News, 37 (6), 3–8. doi:10.1080/08940886.2024.2432265 -

Kaya, M.; Klahn, C.

Design for Additive Manufacturing Education of Process Engineering Students on an Industrial Challenge

2024. Procedia CIRP, 128, 911–916. doi:10.1016/j.procir.2024.06.044 -

Davari, S.; Cárdenas, C.; Hettel, M.; Lott, P.; Tischer, S.; Angeli, S.; Deutschmann, O.

Spatially Resolved Measurements in a Stagnation‐Flow Reactor: Kinetics of Catalytic NH 3 Decomposition

2024. Chemie Ingenieur Technik, 96 (12), 1735–1750. doi:10.1002/cite.202400100 -

Liccardo, G.; Cendejas, M. C.; Mandal, S. C.; Stone, M. L.; Porter, S.; Nhan, B. T.; Kumar, A.; Smith, J.; Plessow, P. N.; Cegelski, L.; Osio-Norgaard, J.; Abild-Pedersen, F.; Chi, M.; Datye, A. K.; Bent, S. F.; Cargnello, M.

Unveiling the Stability of Encapsulated Pt Catalysts Using Nanocrystals and Atomic Layer Deposition

2024. Journal of the American Chemical Society, 146 (34), 23909–23922. doi:10.1021/jacs.4c06423 -

Wang, B.; Da Roit, N.; Zimmermann, M.; Boese, M.; Zevaco, T.; Behrens, S.

Bifunctional catalysts based on PdZn/ZnO and hierarchical zeolites in the direct synthesis of dimethyl ether from CO-rich syngas: influence of the support and the Zn/Pd molar ratio

2024. Catalysis Science & Technology, 14 (24), 7152–7162. doi:10.1039/D4CY00860J -

Dolling, D. S.; Chen, J.; Schober, J.-C.; Creutzburg, M.; Jeromin, A.; Vonk, V.; Sharapa, D. I.; Keller, T. F.; Plessow, P. N.; Noei, H.; Stierle, A.

Probing Active Sites on Pd/Pt Alloy Nanoparticles by CO Adsorption

2024. ACS Nano, 18 (45), 31098–31108. doi:10.1021/acsnano.4c08291 -

Kuhn, C.; Knapp, A.; Deutschmann, M. P.; Spielmann, J.; Tischer, S.; Kramm, U. I.; Nirschl, H.; Deutschmann, O.

Iron as Recyclable Metal Fuel: Unraveling Oxidation Behavior and Cyclization Effects Through Thermogravimetric Analysis, Wide‐Angle X‐ray Scattering and Mössbauer Spectroscopy

2024. ChemSusChem, 17 (15), e202400351. doi:10.1002/cssc.202400351 -

Liu, S.; Klahn, C.

Design and manufacturing of integrated fluidic channels in glass parts by vat-photopolymerization additive manufacturing

2024. Procedia CIRP, 128, 917–922. doi:10.1016/j.procir.2024.05.099 -

Rentschler, P.; Baranowski, S.; Klahn, C.; Dittmeyer, R.

Accelerated design of Power-to-X process chains for transient operation using Recurrent Neural Networks

2024. Procedia CIRP, 128, 668–673. doi:10.1016/j.procir.2024.07.059 -

Chen, J.; Sharapa, D. I.; Plessow, P. N.

Stability of Hydroxylated α-Fe

2024. ACS Omega, 9 (33), 35449–35457. doi:10.1021/acsomega.4c02113 -

Potter, M. E.; Spiske, L.; Plessow, P. N.; McShane, E. B.; Carravetta, M.; Oakley, A. E.; Bere, T.; Carter, J. H.; Vandegehuchte, B. D.; Kaźmierczak, K. M.; Studt, F.; Raja, R.

Combining computational and experimental studies to gain mechanistic insights for n -butane isomerisation with a model microporous catalyst

2024. Catalysis Science & Technology, 14 (24), 7140–7151. doi:10.1039/d4cy01035c -

Dreisbach, M.; Kriegseis, J.; Stroh, A.

Spatio-temporal reconstruction of droplet impingement dynamics by means of color-coded glare points and deep learning

2024. Measurement Science and Technology. doi:10.1088/1361-6501/ad8771 -

Mehdipour, F.; Klahn, C.; Dittmeyer, R.

Multidisciplinary Design Analysis for Wash-Coating of Additively Manufactured Metallic Monoliths

2024. Procedia CIRP, 128, 478–483. doi:10.1016/j.procir.2024.04.012 -

Tountas, A. A.; Dreher, A.; Zhou, W.; Mohan, A.; Kherani, N. P.; Ozin, G. A.; Sain, M. M.

Light-harvesting properties of photocatalyst supports—no photon left behind

2024. npj Computational Materials, 10 (1), Art.-Nr.: 239. doi:10.1038/s41524-024-01409-0 -

Heikkinen, N.; Dhamo, D.; Uotila, I.; Reinikainen, M.; Dittmeyer, R.

Production of C₂ −C₄ Olefins with Fischer‐Tropsch‐Synthesis: The Effect of Cu Promoter Loading on an Fe−Cu−K/SiO₂ Catalyst

2024. ChemCatChem, 16 (19), e202400560. doi:10.1002/cctc.202400560 -

Pan, X.; Cheng, Q.; Gu, X.; Jiang, Y.; Wang, Z.; Hua, M.; Xiao, J.; Jordan, T.; Jiang, J.

Research on the flow characteristics and self-ignition mechanism of high-pressure hydrogen jets in bifurcated tubes

2024. Process Safety and Environmental Protection, 188, 1191–1200. doi:10.1016/j.psep.2024.06.004 -

Wang, Y.; Denisov, N.; Qin, S.; Gonçalves, D. S.; Kim, H.; Sarma, B. B.; Schmuki, P.

Stable and Highly Active Single Atom Configurations for Photocatalytic H 2 Generation

2024. Advanced Materials, 36 (25), Art.-Nr.: 2400626. doi:10.1002/adma.202400626 -

Klag, L.; Gläser, R.; Krewer, U.; Reuter, K.; Grunwaldt, J.-D.

Special Collection: Catalysts and Reactors under Dynamic Conditions for Energy Storage and Conversion

2024. ChemCatChem, 16 (21), Art.-Nr.: 202401191. doi:10.1002/cctc.202401191 -

Mahmoudizadeh, M.; Klahn, C.; Dittmeyer, R.

Innovative Autothermal Reactor Design via Additive Manufacturing: Optimization of Catalytic Exothermic Reactions Using Porous Media for Heat Management

2024. Procedia CIRP, 128, 411–417. doi:10.1016/j.procir.2024.04.011 -

Siegert, F.; Gundermann, M.; Maurer, L.; Hahn, S.; Hofmann, J.; Distel, M.; Schühle, J.; Müller, K.; Wolf, M.; Preuster, P.; Auer, F.; Geißelbrecht, M.; Wasserscheid, P.

Autothermal hydrogen release from liquid organic hydrogen carrier systems

2024. International Journal of Hydrogen Energy, 91, 834–842. doi:10.1016/j.ijhydene.2024.10.044 -

Biffar, L.; Pham, A. T.; Benzinger, W.; Pfeifer, P.

Performance of a RuCs/MgO catalyst coated on additive manufactured support structures via electrophoretic deposition for ammonia synthesis

2024. Chemical Engineering and Processing - Process Intensification, 205, Art.-Nr.: 110019. doi:10.1016/j.cep.2024.110019 -

Mahmoudizadeh, M.; Klahn, C.; Dittmeyer, R.

Powder bed fusion of solid and permeable Crofer 22 APU parts for applications in chemical process engineering

2024. Progress in Additive Manufacturing. doi:10.1007/s40964-024-00811-w -

Rui, S.; Xiao, J.; Wang, C.; Wang, F.; Kuznetsov, M.; Jordan, T.

Numerical study of external explosion in vented hydrogen explosions

2024. Process Safety and Environmental Protection, 191 (A), 1516–1533. doi:10.1016/j.psep.2024.09.022 -

Vergara, T.; Gómez, D.; Warmuth, L.; Enß, A. E.; Peterlechner, M.; Pallacán, R.; Diaconescu, V. M.; Simonelli, L.; Studt, F.; Concepción, P.; Jiménez, R.; Karelovic, A.

On the Structure Sensitivity of CO

2024. ACS Catalysis, 14 (18), 14127 – 14138. doi:10.1021/acscatal.4c03803 -

Mockenhaupt, B.; Gieser, J.; Najafishirtari, S.; Baumgarten, L.; Jelic, J.; Lunkenbein, T.; Ras, E.-J.; Grunwaldt, J.-D.; Studt, F.; Behrens, M.

On the secondary promotion effect of Al and Ga on Cu/ZnO methanol synthesis catalysts

2024. Journal of Catalysis, 439, Art.-Nr.: 115785. doi:10.1016/j.jcat.2024.115785 -

Kuhn, C.; Kirn, M.; Tischer, S.; Deutschmann, O.

Micron-sized iron particles as energy carrier: Cycling experiments in a fixed-bed reactor

2024. Proceedings of the Combustion Institute, 40 (1-4), 105207. doi:10.1016/j.proci.2024.105207 -

Sen, K.; Schäfer, A.; Rosowski, F.; Sharapa, D. I.; Studt, F.

Quantum Chemical Modeling of the Full Catalytic Cycle for Selective Oxidation of Propane to Propene on the M1 Phase of Mo–Te–Nb–O Mixed-Metal Oxide Catalysts

2024. The Journal of Physical Chemistry C, 128 (34), 14273–14281. doi:10.1021/acs.jpcc.4c02899 -

Martins, T.; Sá, M. S. de; Silva, W. R.; Carriel Schmitt, C.; Moreira, R.; Raffelt, K.; Dahmen, N.; Wisniewski, A., Jr

Sugarcane biorefinery: Unlocking the potential of the pyrolytic process to convert waste biomasses into value-added products

2024. Energy Conversion and Management, 318, 118913. doi:10.1016/j.enconman.2024.118913 -

Enss, A. E.; Huber, P.; Plessow, P. N.; Studt, F.

Methanol-Mediated Hydrogen Transfer Reactions at Surface Lewis Acid Sites of H-SSZ-13

2024. The Journal of Physical Chemistry C, 128 (37), 15367–15379. doi:10.1021/acs.jpcc.4c03408 -

Villagra-Soza, F.; Vergara, T.; Godoy, S.; Karelovic, A.; Jiménez, R.

Unraveling the mechanistic interplay between CO and CO

2024. Journal of Catalysis, 438, 115726. doi:10.1016/j.jcat.2024.115726 -

Mokashi, M.; Shirsath, A. B.; Demir, S.; Çelik, A.; Lott, P.; Tischer, S.; Deutschmann, O.

Kinetics of thermal dry reforming of methane for syngas production and solid carbon capture

2024. Reaction Chemistry & Engineering, 9 (11), 2902–2914. doi:10.1039/d4re00312h -

Paripsa, S.; Gaur, A.; Förste, F.; Doronkin, D. E.; Malzer, W.; Schlesiger, C.; Kanngießer, B.; Welter, E.; Grunwaldt, J.-D.; Lützenkirchen-Hecht, D.

RefXAS: an open access database of X-ray absorption spectra

2024. Journal of Synchrotron Radiation, 31 (5), 1105–1117. doi:10.1107/S1600577524006751 -

Das, S.; Kahnt, M.; van Valen, Y.; Bergh, T.; Blomberg, S.; Lyubomirskiy, M.; Schroer, C. G.; Venvik, H. J.; Sheppard, T. L.

Restructuring of Ag catalysts for methanol to formaldehyde conversion studied using in situ X-ray ptychography and electron microscopy

2024. Catalysis Science & Technology, 14 (20), 5885–5898. doi:10.1039/D4CY00770K -

Chowdhury, A. G.; Arnold, U.; Garbev, K.; Bender, M.; Sauer, J.

Direct dehydrogenation of methanol to formaldehyde over ZnO–SiO

2024. Catalysis Science and Technology, 14 (17), 4958–4967. doi:10.1039/D4CY00541D -

Zhou, S.; Xiao, J.; Luo, Z.; Kuznetsov, M.; Chen, Z.; Jordan, T.; Banuti, D. T.

Analysis of spontaneous ignition of hydrogen-enriched methane in a rectangular tube

2024. Proceedings of the Combustion Institute, 40 (1-4), 105681. doi:10.1016/j.proci.2024.105681 -

Guse, D.; Warmuth, L.; Herfet, M.; Adolf, K.; Zevaco, T. A.; Pitter, S.; Kind, M.

Seeding as a Decisive Tool for Increasing Space-Time-Yields in the Preparation of High-Quality Cu/ZnO/ZrO₂ Catalysts

2024. Catalysts, 14 (8), Article no: 517. doi:10.3390/catal14080517 -

Mahayni, Y.; Maurer, L.; Auer, F.; Hutzler, A.; Wasserscheid, P.; Wolf, M.

Structure sensitivity of the low temperature dehydrogenation of perhydro (di)benzyltoluene on supported platinum nanoparticles

2024. Catalysis Science & Technology, 14 (18), 5464–5473. doi:10.1039/D4CY00032C -

Weber, S.; Karpov, D.; Kahnt, M.; Diaz, A.; Romanenko, Y.; Kotrel, S.; Haas, A.; Hinrichsen, B.; Bottke, N.; Grunwaldt, J.-D.; Schunk, S.; Sheppard, T. L.

Multimodal Hard X‐ray Nanotomography Probes Pore Accessibility of Technical Catalysts after Coking

2024. ChemCatChem, 16 (22), e202301298. doi:10.1002/cctc.202301298 -

Maurer, L. A.; Pham, C. v.; Fritsch, B.; Jeppesen, H. S.; Etter, M.; Hutzler, A.; Neder, R. B.; Wolf, M.; Auer, F.; Thiele, S.; Wasserscheid, P.

Improving Hydrogen Release From Oxygen‐Functionalized LOHC Molecules by Ru Addition to Pt/C Catalysts

2024. ChemCatChem, e202400375. doi:10.1002/cctc.202400375 -

Bäuerle, M.; Paintner, T.; Schmolke, D.; Systermans, T.; Kinnen, W.; Jordan, T.

H

2024. Chemie Ingenieur Technik, 96 (1-2), 211–219. doi:10.1002/cite.202300145 -

Otroshchenko, T.; Sharapa, D. I.; Fedorova, E. A.; Zhao, D.; Kondratenko, E. V.

Highly Efficient Low‐loaded PdOx/AlSiOx for Ethylene Dimerization

2024. Angewandte Chemie International Edition, 63 (44), e202410646. doi:10.1002/anie.202410646 -

Hübner, J. L.; Lucchetti, L. E. B.; Nong, H. N.; Sharapa, D. I.; Paul, B.; Kroschel, M.; Kang, J.; Teschner, D.; Behrens, S.; Studt, F.; Knop-Gericke, A.; Siahrostami, S.; Strasser, P.

Cation Effects on the Acidic Oxygen Reduction Reaction at Carbon Surfaces

2024. ACS Energy Letters, 9 (4), 1331–1338. doi:10.1021/acsenergylett.3c02743 -

Gietzelt, T.; Walter, M.; Toth, V.; Messerschmidt, F.

On the suitability of alloys with a high molybdenum content ...for the manufacture of corrosion-resistant microprocessing equipment by diffusion welding - Part 1 of 2. Corrosion aspects, materials and corrosion and diffusion welding tests; [über die Eignung von hoch molybdänhaltigen Legierungen]

2024. Galvanotechnik, 115 (6), 742 – 749 -

Borchers, M.; Förster, J.; Thrän, D.; Beck, S.; Thoni, T.; Korte, K.; Gawel, E.; Markus, T.; Schaller, R.; Rhoden, I.; Chi, Y.; Dahmen, N.; Dittmeyer, R.; Dolch, T.; Dold, C.; Herbst, M.; Heß, D.; Kalhori, A.; Koop-Jakobsen, K.; Li, Z.; Oschlies, A.; Reusch, T. B. H.; Sachs, T.; Schmidt-Hattenberger, C.; Stevenson, A.; Wu, J.; Yeates, C.; Mengis, N.

A Comprehensive Assessment of Carbon Dioxide Removal Options for Germany

2024. Earth’s Future, 12 (5), e2023EF003986. doi:10.1029/2023EF003986 -

Daga, M.; Sanna, C.; Bais, G.; Polentarutti, M.; Massardo, S.; Carnasciali, M.; Holtappels, P.; Costamagna, P.; Pani, M.; Artini, C.

Impact of the electrospinning synthesis route on the structural and electrocatalytic features of the LSCF (La0.6Sr0.4Co0.2Fe0.8O3–δ) perovskite for application in solid oxide fuel cells

2024. Solid State Ionics, 413, Art.-Nr.: 116620. doi:10.1016/j.ssi.2024.116620 -

Sarma, B. B.; Neukum, D.; Doronkin, D. E.; Lakshmi Nilayam, A. R.; Baumgarten, L.; Krause, B.; Grunwaldt, J.-D.

Understanding the role of supported Rh atoms and clusters during hydroformylation and CO hydrogenation reactions with in situ / operando XAS and DRIFT spectroscopy

2024. Chemical Science, 15 (31), 12369–12379. doi:10.1039/D4SC02907K -

Braun, L.; Spielmann, J.; Doronkin, D. E.; Kuhn, C.; Maliugin, A.; Sharapa, D. I.; Huck, I.; Bao, J.; Tischer, S.; Studt, F.; Deutschmann, O.; Kramm, U. I.; Grunwaldt, J.-D.

Following the Structural Changes of Iron Oxides during Reduction under Transient Conditions

2024. ChemSusChem, 17 (24), Art.-Nr.: e202401045. doi:10.1002/cssc.202401045 -

Grosselindemann, C.; Dorn, M.; Bauer, F. M.; Seim, M.; Ewald, D.; Esau, D.; Geörg, M.; Rössler, R.; Pundt, A.; Weber, A.

Pressurized single cell testing of solid oxide cells

2024. Journal of Power Sources, 614, Art.-Nr.: 234963. doi:10.1016/j.jpowsour.2024.234963 -

Rex, A.; Almeida De Campos, L.; Gottschalk, T.; Ferreira Sanchez, D.; Trinke, P.; Czioska, S.; Saraçi, E.; Bensmann, B.; Grunwaldt, J.-D.; Hanke-Rauschenbach, R.; Sheppard, T. L.

Elemental Distribution in Catalyst‐Coated Membranes of Proton Exchange Membrane Water Electrolysers Tracked by Synchrotron X‐Ray Fluorescence

2024. Advanced Energy and Sustainability Research, 5 (9), Art.-Nr.: 2400048. doi:10.1002/aesr.202400048 -

Hecimovic, A.; Mayer, M. T.; de Haart, L. G. J.; Gupta, S.; Kiefer, C. K.; Navarrete, A.; Schulz, A.; Fantz, U.

Benchmarking microwave-induced CO

2024. Journal of CO2 Utilization, 83, Art.-Nr.: 102825. doi:10.1016/j.jcou.2024.102825 -

Li, J.; Šimek Tosino, H.; Ladewig, B. P.; Jung, N.; Bräse, S.; Dittmeyer, R.

Extraction of the intrinsic rate constant for a photocyclization reaction in capillary microreactors using a simplified reactor model

2024. Reaction Chemistry & Engineering, 9 (8), 2149–2159. doi:10.1039/d4re00087k -

Rybakov, K. I.; Mahmoud, M. M.; Link, G.

Analysis of microwave heating of copper powder compacts

2024. Materials Chemistry and Physics, 322, Artklnr.: 129548. doi:10.1016/j.matchemphys.2024.129548 -

Grosselindemann, C.; Reddy, M. J.; Störmer, H.; Esau, D.; Dorn, M.; Bauer, F. M.; Ewald, D.; Wissmeier, L.; Froitzheim, J.; Weber, A.

Impact of CeCo-Coated Metallic Interconnectors on SOCs Towards Performance, Cr-Oxide-Scale, and Cr-Evaporation

2024. Journal of The Electrochemical Society, 171 (5), Art.-Nr.: 054508. doi:10.1149/1945-7111/ad44da -

Sarma, B. B.; Grunwaldt, J.-D.

Operando Spectroscopy to Understand Dynamic Structural Changes of Solid Catalysts

2024. CHIMIA, 78 (5), 288–296. doi:10.2533/chimia.2024.288 -

Enss, A. E.; Plessow, P. N.; Studt, F.

Theoretical investigation of the paring mechanism of the MTO process in different zeolites

2024. Journal of Catalysis, 432, Art.-Nr.: 115363. doi:10.1016/j.jcat.2024.115363 -

Biffar, L.; Benzinger, W.; Pfeifer, P.

A Simplified Approach for Calculating Heat Transfer Coefficients for Fluid Guiding Elements with Alternating Redirections of Flow

2024. Chemie Ingenieur Technik, 96 (8), 1116–1122. doi:10.1002/cite.202300104 -

El Mellas, I.; Samkhaniani, N.; Falsetti, C.; Stroh, A.; Icardi, M.; Magnini, M.

Numerical investigation of bubble dynamics and flow boiling heat transfer in cylindrical micro-pin-fin heat exchangers

2024. International Journal of Heat and Mass Transfer, 228, Art.-Nr.: 125620. doi:10.1016/j.ijheatmasstransfer.2024.125620 -

Doering, M.; Trinkies, L. L.; Kieninger, J.; Kraut, M.; Rupitsch, S. J.; Dittmeyer, R.; Urban, G. A.; Weltin, A.

In Situ Performance Monitoring of Electrochemical Oxygen and Hydrogen Peroxide Sensors in an Additively Manufactured Modular Microreactor

2024. ACS Omega, 9 (17), 19700–19711. doi:10.1021/acsomega.4c02210 -

Dhamo, D.; Kühn, J.; Lüttin, S.; Rubin, M.; Dittmeyer, R.

Coupling the high-temperature Fischer–Tropsch synthesis and the skeletal isomerization reaction at optimal operation conditions in the Power-to-Fuels process route for the production of sustainable aviation gasoline

2024. Sustainable Energy & Fuels, 8 (9), 2094–2103. doi:10.1039/d3se01351k -

Crone, M.; Trinkies, L. L.; Dittmeyer, R.; Türk, M.

Deposition of Pd, Pt, and PdPt Nanoparticles on TiO

2024. Molecules, 29 (9), Art.-Nr.: 2142. doi:10.3390/molecules29092142 -

Metzger, D. F.; Klahn, C.; Dittmeyer, R.

A Simplified Design Method for the Mechanical Stability of Slit-Shaped Additively Manufactured Reactor Modules

2024. Designs, 8 (3), Art.-Nr.: 41. doi:10.3390/designs8030041 -

Yang, J.; Stroh, A.; Lee, S.; Bagheri, S.; Frohnapfel, B.; Forooghi, P.

Assessment of Roughness Characterization Methods for Data-Driven Predictions

2024. Flow, Turbulence and Combustion, 113 (2), 275–292. doi:10.1007/s10494-024-00549-z -

Oppel, N.; Röse, P.; Heuser, S.; Prokein, M.; Apfel, U.-P.; Krewer, U.

Unveiling the kinetics of CO

2024. Electrochimica Acta, 490, Art.-Nr.: 144270. doi:10.1016/j.electacta.2024.144270 -

Tusini, E.; Casapu, M.; Zimina, A.; Doronkin, D. E.; Störmer, H.; Barthe, L.; Belin, S.; Grunwaldt, J.-D.

Structural Changes of Ni and Ni–Pt Methane Steam Reforming Catalysts During Activation, Reaction, and Deactivation Under Dynamic Reaction Conditions

2024. ACS Catalysis, 7463–7477. doi:10.1021/acscatal.3c05847 -

Scotti, N.; Borsacchi, S.; Monti, S.; Zimina, A.; Evangelisti, C.; Geppi, M.; Dambruoso, P.; Barcaro, G.; Bossola, F.; Dal Santo, V.; Ravasio, N.

Spectroscopic and theoretical investigation of Brønsted acid sites in amorphous mixed Zr-Si oxide nanoparticles

2024. Journal of Alloys and Compounds, 992, Article no: 174545. doi:10.1016/j.jallcom.2024.174545 -

Spielmann, J.; Braig, D.; Streck, A.; Gustmann, T.; Kuhn, C.; Reinauer, F.; Kurnosov, A.; Leubner, O.; Potapkin, V.; Hasse, C.; Deutschmann, O.; Etzold, B. J. M.; Scholtissek, A.; Kramm, U. I.

Exploring the oxidation behavior of undiluted and diluted iron particles for energy storage: Mössbauer spectroscopic analysis and kinetic modeling

2024. Physical Chemistry Chemical Physics, 26 (17), 13049–13060. doi:10.1039/d3cp03484d -

Schmitt, C.; Da Roit, N.; Neumaier, M.; Maliakkal, C. B.; Wang, D.; Henrich, T.; Kübel, C.; Kappes, M.; Behrens, S.

Continuous flow synthesis of atom-precise platinum clusters

2024. Nanoscale Advances. doi:10.1039/d4na00074a -

Münzer, P.; Arnold, U.; Sauer, J.

Process Design for the Directly Coupled Production of Methanol and Formaldehyde Based on CO

2024. Chemie Ingenieur Technik, 96 (6), 819–825. doi:10.1002/cite.202300183 -

Hirth, T.; Jordan, T.

Wasserstoff [Editorial]

2024. Chemie Ingenieur Technik, 96 (1-2), 3–3. doi:10.1002/cite.202470102 -

Toprak, M.; Samkhaniani, N.; Stroh, A.

Drop rebounding on heated micro-textured surfaces

2024. International Journal of Heat and Mass Transfer, 227, Artk.Nr.: 125498. doi:10.1016/j.ijheatmasstransfer.2024.125498 -

Eberhard, A.; Metni, H.; Fahland, G.; Stroh, A.; Friederich, P.

Actively learning costly reward functions for reinforcement learning

2024. Machine Learning: Science and Technology, 5 (1), Art.-Nr.: 015055. doi:10.1088/2632-2153/ad33e0 -

Das, S.; Stuckelberger, M. E.; Pottbacker, J.; Jakobtorweihen, S.; Schroer, C. G.; Horn, R.; Sheppard, T. L.

Quantitative Chemical Mapping of Pt/Rh Gauze Catalysts for Ammonia Oxidation using Resonant X-ray Tomography

2024. The Journal of Physical Chemistry C, 128 (12), 5053–5063. doi:10.1021/acs.jpcc.4c00041 -

Mokashi, M.; Shirsath, A. B.; Çelik, A.; Lott, P.; Müller, H.; Tischer, S.; Maier, L.; Bode, J.; Schlereth, D.; Scheiff, F.; Flick, D.; Bender, M.; Ehrhardt, K.; Deutschmann, O.

Methane pyrolysis in packed bed reactors: Kinetic modeling, numerical simulations, and experimental insights

2024. Chemical Engineering Journal, 485, Art.-Nr.: 149684. doi:10.1016/j.cej.2024.149684 -

Hagg, D.; Eifert, A.; Troßmann, T.; Frohnapfel, B.; Marschall, H.; Wörner, M.

Numerical study of liquid imbibition and contact line pinning in a sealing gap for corrosion protection of metal housings

2024. Progress in Computational Fluid Dynamics, An International Journal, 24 (2), 65 – 77. doi:10.1504/PCFD.2024.137058 -

Rosmini, C.; Pazos Urrea, M.; Tusini, E.; Indris, S.; Kovacheva, D.; Karashanova, D.; Kolev, H.; Zimina, A.; Grunwaldt, J.-D.; Rønning, M.; Dimitrov, M.; Popova, M.

Unveiling the synergistic effects of pH and Sn content for tuning the catalytic performance of Ni^0/Ni_{x}Sn_{y} intermetallic compounds dispersed on Ce-Zr mixed oxides in the aqueous phase reforming of ethylene glycol

2024. Applied catalysis / B, 350, Art.Nr.: 123904. doi:10.1016/j.apcatb.2024.123904 -

Pazos Urrea, M.; Meilinger, S.; Herold, F.; Gopakumar, J.; Tusini, E.; De Giacinto, A.; Zimina, A.; Grunwaldt, J.-D.; Chen, D.; Rønning, M.

Aqueous Phase Reforming over Platinum Catalysts on Doped Carbon Supports: Exploring Platinum–Heteroatom Interactions

2024. ACS Catalysis, 14 (6), 4139–4154. doi:10.1021/acscatal.3c05385 -

Neukum, D.; Saraçi, E.; Wüst, D.; Raj Lakshmi Nilayam, A.; Sharma, S.; Grunwaldt, J.-D.

Rational process design for the efficient oxidation of crude HMF-solution using AuPd/C catalysts

2024. Catalysis Today, 432, Article no: 114615. doi:10.1016/j.cattod.2024.114615 -

Zhang, Q.; Li, Y.; Otroshchenko, T.; Kondratenko, V. A.; Wu, K.; Fedorova, E. A.; Doronkin, D. E.; Bartling, S.; Lund, H.; Jiang, G.; Kondratenko, E. V.

The enhancing effect of Co

2024. Journal of Catalysis, 432, Art.-Nr.: 115440. doi:10.1016/j.jcat.2024.115440 -

Huang, J.; Klahn, M.; Tian, X.; Bartling, S.; Zimina, A.; Radtke, M.; Rockstroh, N.; Naliwajko, P.; Steinfeldt, N.; Peppel, T.; Grunwaldt, J.-D.; Logsdail, A. J.; Jiao, H.; Strunk, J.

Fundamental structural and electronic understanding of palladium catalysts on nitride and oxide supports

2024. Angewandte Chemie International Edition, Art.Nr.: e202400174. doi:10.1002/anie.202400174 -

Smitshuysen, T. E. L.; Lützen, M.; Zimina, A.; Sheppard, T. L.; Jakobsen, H. H.; Chorkendorff, I.; Damsgaard, C. D.

Using CoCu

2024. Applied Catalysis A: General, 675, 119636. doi:10.1016/j.apcata.2024.119636 -

Neukum, D.; Lakshmi Nilayam, A. R.; Ludwig, M. E.; Vadarlis, A. A.; Grunwaldt, J.-D.; Saraçi, E.

Continuous flow oxidation of HMF using supported AuPd-alloy

2024. Catalysis Science & Technology, 14 (8), 2130–2138. doi:10.1039/D3CY01722B -

Rodrigues Niquini, G.; Lacerda de Oliveira Campos, B.; Herrera Delgado, K.; Pitter, S.; Sauer, J.

Experimental study and comprehensive kinetic modeling of the direct dimethyl ether synthesis on Cu/ZnO/ZrO₂ and H-FER-20

2024. Chemical Engineering Journal, 480, Art.-Nr.: 147968. doi:10.1016/j.cej.2023.147968 -

Nikolajsen, M. T.; Grivel, J.-C.; Gaur, A.; Hansen, L. P.; Baumgarten, L.; Schjødt, N. C.; Mentzel, U. V.; Grunwaldt, J.-D.; Sehested, J.; Christensen, J. M.; Høj, M.

Surface ZnO

2024. Journal of Catalysis, 431, Art.-Nr.: 115389. doi:10.1016/j.jcat.2024.115389 -

Chawla, J.; Schardt, S.; Lott, P.; Angeli, S.; Tischer, S.; Maier, L.; Deutschmann, O.

Detailed kinetic modeling of catalytic oxidative coupling of methane

2024. Chemical Engineering Journal, 482, Art-Nr.: 148719. doi:10.1016/j.cej.2024.148719 -

Khoshkalam, M.; Farzin, Y. A.; Sjølin, B. H.; Spezzati, C.; Holtappels, P.; Castelli, I. E.; Sudireddy, B. R.

Rapid Solid‐State Gas Sensing Realized via Fast K + Transport Kinetics in Earth Abundant Rock‐Silicates

2024. Advanced Engineering Materials, 26 (8), Art.-Nr.: 2302231. doi:10.1002/adem.202302231 -

Frohnapfel, B.; Deyn, L. von; Yang, J.; Neuhauser, J.; Stroh, A.; Örlü, R.; Gatti, D.

Flow resistance over heterogeneous roughness made of spanwise-alternating sandpaper strips

2024. Journal of Fluid Mechanics, 980, 1–35. doi:10.1017/jfm.2024.40 -

Warmuth, L.; Steurer, M.; Schild, D.; Zimina, A.; Grunwaldt, J.-D.; Pitter, S.

Reversible and Irreversible Structural Changes in Cu/ZnO/ZrO₂ Catalysts during Methanol Synthesis

2024. ACS Applied Materials & Interfaces, 16 (7), 8813–8821. doi:10.1021/acsami.3c17383 -

Mehdipour, F.; Delrieux, T.; Maurer, F.; Grunwaldt, J.-D.; Klahn, C.; Dittmeyer, R.

Opportunities and limitations of metal additive manufacturing of structured catalytic converters

2024. Catalysis Communications, 187, 106873. doi:10.1016/j.catcom.2024.106873 -

Chacko, R.; Goßler, H.; Angeli, S.; Deutschmann, O.

Interconnected Digital Solutions to Accelerate Modeling of the Reaction Kinetics in Catalysis

2024. ChemCatChem, 16 (4), Art.-Nr.: e202301355. doi:10.1002/cctc.202301355 -

Zeh, A.; Zimmermann, M.; Albert, R.; Drüppel, K.; Gerdes, A.

Zircon U-Pb-Hf isotope systematics of southern Black Forest gneiss units (Germany) – Implications for the pre-Variscan evolution of Central Europe

2024. Gondwana Research, 128, 351–367. doi:10.1016/j.gr.2023.11.008 -

Neukum, D.; Saraci, E.; Krause, B.; Nilayam, A. R. L.; Sinigalia, A.; Grunwaldt, J.-D.

Pushing the Efficiency of the Selective and Base‐free Air‐Oxidation of HMF by Varying the Properties of Carbon‐based Supports

2024. ChemCatChem, 16 (10), e202301228. doi:10.1002/cctc.202301228 -

Klag, L.; Baumgarten, L.; Gaur, A.; Sheppard, T. L.; Grunwaldt, J.-D.

Comparison of Structure and Reactivity of Hydrothermally Prepared Bi‐Mo‐Co‐Fe‐O Catalysts in Selective Propylene and Isobutene Oxidation

2024. ChemCatChem, Art.-Nr.: e202301470. doi:10.1002/cctc.202301470 -

Lacerda de Oliveira Campos, B.; Oliveira Souza da Costa, A.; Herrera Delgado, K.; Pitter, S.; Sauer, J.; Ferreira da Costa Junior, E.

Development of a surrogate artificial neural network for microkinetic modeling: case study with methanol synthesis

2024. Reaction Chemistry & Engineering, 9 (5), 1047–1060. doi:10.1039/d3re00409k -

Chen, S.; Jelic, J.; Rein, D.; Najafishirtari, S.; Schmidt, F.-P.; Girgsdies, F.; Kang, L.; Wandzilak, A.; Rabe, A.; Doronkin, D. E.; Wang, J.; Friedel Ortega, K.; DeBeer, S.; Grunwaldt, J.-D.; Schlögl, R.; Lunkenbein, T.; Studt, F.; Behrens, M.

Highly loaded bimetallic iron-cobalt catalysts for hydrogen release from ammonia

2024. Nature Communications, 15 (1), Art.-Nr.: 871. doi:10.1038/s41467-023-44661-6 -

Strauch, D.; Weiner, P.; Sarma, B. B.; Körner, A.; Herzinger, E.; Wolf, P.; Zimina, A.; Hutzler, A.; Doronkin, D. E.; Grunwaldt, J.-D.; Wasserscheid, P.; Wolf, M.

Bimetallic platinum rhenium catalyst for efficient low temperature dehydrogenation of perhydro benzyltoluene

2024. Catalysis Science & Technology, 14 (7), 1775–1790. doi:10.1039/D3CY01336G -

Hodonj, D.; Borchers, M.; Zeh, L.; Hoang, G. T.; Tischer, S.; Lott, P.; Deutschmann, O.

Impact of operation parameters and lambda input signal during lambda-dithering of three-way catalysts for low-temperature performance enhancement

2024. Applied Catalysis B: Environmental, 345, Art.-Nr.: 123657. doi:10.1016/j.apcatb.2023.123657 -

Jordan, T.

Multimodaler Wasserstoff-Hub in der Innovationsregion Fessenheim [Multimodal Hydrogen Hub in the Fessenheim Innovation Region]

2024. Chemie Ingenieur Technik, 96 (1-2), 220–233. doi:10.1002/cite.202300240 -

Klag, L.; Weber, S.; Horn, R.; Sheppard, T. L.; Grunwaldt, J.-D.

Exploring structure, temperature and activity correlations in the selective oxidation of lower olefins over Bi-Mo-Co-Fe-O catalysts by spatial reactor profile measurements

2024. Catalysis Science & Technology, 14 (4), 863–877. doi:10.1039/D3CY01445B -

Rodrigues Niquini, G.; Münzer, P.; Ebrahim-Moghaddam, M.; Warmuth, L.; Herrera Delgado, K.; Pitter, S.; Dahmen, N.; Sauer, J.

Regenerativ erzeugter Wasserstoff – Perspektiven in chemischen Wertschöpfungsketten [Regeneratively Produced Hydrogen – Perspectives in Chemical Value Chains]

2024. Chemie Ingenieur Technik, 96 (1-2), 100–113. doi:10.1002/cite.202300221 -

Shekhar, S.; Chowdhury, C.

Topological data analysis enhanced prediction of hydrogen storage in metal–organic frameworks (MOFs)

2024. Materials Advances, 2024 (5), 820–830. doi:10.1039/D3MA00591G -

Herzinger, E.; Wolf, M.

Perspectives and Potential of Liquid Organic Hydrogen Carriers in the German Energy Scenario

2024. Chemie Ingenieur Technik, 96 (1-2), 65–73. doi:10.1002/cite.202300227 -

Zimina, A.; Léon, A.; Steininger, R.

Chemical bonding effects in Sc compounds studied using X-ray absorption and X-ray photoelectron spectroscopies

2024. Physical Chemistry Chemical Physics, 26 (3), 2613–2621. doi:10.1039/D3CP04108E -

Sheikh, K. A.; Zaghini Francesconi, V.; Zevaco, T. A.; Sauer, J.

Carbonylation of dimethoxymethane: a study on the reactivity of different solid acid catalysts

2024. Catalysis Science & Technology, 14, 1148–1166. doi:10.1039/D3CY01286G -

Yang, M.; Yu, J.; Zimina, A.; Sarma, B. B.; Grunwaldt, J.-D.; Zada, H.; Wang, L.; Sun, J.

Unlocking a Dual‐Channel Pathway in CO

2024. Angewandte Chemie - International Edition, 63 (4), Art.Nr.: e202312292. doi:10.1002/anie.202312292 -

Mokashi, M.; Bhimrao Shirsath, A.; Lott, P.; Müller, H.; Tischer, S.; Maier, L.; Deutschmann, O.

Understanding of gas-phase methane pyrolysis towards hydrogen and solid carbon with detailed kinetic simulations and experiments

2024. Chemical Engineering Journal, 479, Art.Nr.: 147556. doi:10.1016/j.cej.2023.147556 -

Trinkies, L. L.; Crone, M.; Türk, M.; Kraut, M.; Dittmeyer, R.

Supercritical deposition of mono- and bimetallic Pd and Pt on TiO 2 coated additively manufactured substrates for the application in the direct synthesis of hydrogen peroxide

2024. Chemical Engineering and Processing - Process Intensification, 195, 109618. doi:10.1016/j.cep.2023.109618 -

Zhao, D.; Kondratenko, V. A.; Doronkin, D. E.; Han, S.; Grunwaldt, J.-D.; Rodemerck, U.; Linke, D.; Kondratenko, E. V.

Effect of supports on the kind of in-situ formed ZnOₓ species and its consequence for non-oxidative propane dehydrogenation

2024. Catalysis Today, 428, 114444. doi:10.1016/j.cattod.2023.114444 -

Lott, P.; Casapu, M.; Grunwaldt, J.-D.; Deutschmann, O.

A review on exhaust gas after-treatment of lean-burn natural gas engines – From fundamentals to application

2024. Applied Catalysis B: Environmental, 340, Art.Nr.: 123241. doi:10.1016/j.apcatb.2023.123241 -

Hinge, V. K.; Bairagi, M.; Yadav, N.; Joshi, S. K.; Shrivastava, B. D.; Jha, S. N.; Bhattacharya, D.; Gaur, A.

Investigating local coordination and electronic nature of Cu centers in the copper complexes having aspartic and glutamic acids

2024. X-Ray Spectrometry, 53 (1), 60–68. doi:10.1002/xrs.3369

-

Sun, C.; Li, N.; Link, G.

Microwave-assisted High-speed Winding of Continuous Carbon Fiber Reinforced Thermoplastic Composites

2024. 2024 Asia-Pacific Microwave Conference (APMC), 1305–1307, Institute of Electrical and Electronics Engineers (IEEE). doi:10.1109/APMC60911.2024.10867728 -

Kollmer, M.; Vogelbacher, M.; Terzi, M.; Singh, M.; Vidal-Vazquez, F.; Matthes, J.

Demand Response for a Novel Decentralized Power-To-Methanol Process

2024. Proceedings IEEE 7th International Conference on Smart Energy Systems and Technologies, Torino, Italy, 10-12 September 2024., 1–6, Institute of Electrical and Electronics Engineers (IEEE). doi:10.1109/SEST61601.2024.10694417

-

Mueller, M.; Dittmeyer, R.

Wind-to-Hydrogen Tech Goes to Sea: Is Electrolysis Cheaper Offshore? A New Project will Find Out

2023. IEEE Spectrum, 60 (9), 24–29. doi:10.1109/MSPEC.2023.10234178 -

Dolcet, P.; Grunwaldt, J.-D.; Hövelmann, S.; Amelung, L.; Schneidewind, A.

DAta from PHoton and Neutron Experiments – DAPHNE4NFDI – Annual Meeting 2023

2023. Synchrotron Radiation News, 36 (6), 55–57. doi:10.1080/08940886.2023.2277655 -

Jordan, T.; Askar, E.; Holtappels, K.; Deeg, S.; Jopen, M.; Stoll, U.; Reinecke, E.-A.; Krause, U.; Beyer, M.; Markus, D.

Stand der Kenntnisse und Technik bezüglich Wasserstoffsicherheit

2023. Chemie Ingenieur Technik, 96 (1-2), 192–210. doi:10.1002/cite.202300141 -

Rentschler, P.; Klahn, C.; Dittmeyer, R.

The Need for Dynamic Process Simulation: A Review of Offshore Power‐to‐X Systems

2023. Chemie Ingenieur Technik, 96 (1-2). doi:10.1002/cite.202300156 -

Scholz, B.; Oshchepkov, A. S.; Papaianina, O.; Ruppenstein, C.; Akhmetov, V. A.; Sharapa, D. I.; Amsharov, K. Y.; Pérez-Ojeda, M. E.

An Indacenopicene‐based Buckybowl Catcher for Recognition of Fullerenes

2023. Chemistry – A European Journal, 29 (70), Art.-Nr.: e202303814. doi:10.1002/chem.202303814 -

Grosselindemann, C.; Kullmann, F.; Lehnert, T.; Fritz, O.; Fuchs, F.-M.; Weber, A.

Comparison of a solid oxide cell with nickel/gadolinium‐doped ceria fuel electrode during operation with hydrogen/steam and carbon monoxide/carbon dioxide

2023. Fuel Cells, 23 (6), 442–453. doi:10.1002/fuce.202300060 -

Cirrone, D.; Makarov, D.; Kashkarov, S.; Friedrich, A.; Molkov, V.

Physical model of non-adiabatic blowdown of cryo-compressed hydrogen storage tanks

2023. International Journal of Hydrogen Energy, 48 (90), 35387–35406. doi:10.1016/j.ijhydene.2023.05.182 -

Brübach, L.; Trützler, D.; Hodonj, D.; Pfeifer, P.

Influence of Recycle Operation on the Catalytic Hydrogenation of CO 2 to Long-Chain Hydrocarbons

2023. Industrial & Engineering Chemistry Research, 62 (1), 199–210. doi:10.1021/acs.iecr.2c03452 -

Li, N.; Link, G.; Jelonnek, J.; Ong, S. K.

Digital Twins towards Microwave-assisted 3D Printing of Continuous Carbon Fiber Reinforced Composites

2023. Procedia CIRP, 119, 158–163. doi:10.1016/j.procir.2023.03.088 -

Vergara, T.; Gómez, D.; Lacerda de Oliveira Campos, B.; Herrera Delgado, K.; Jiménez, R.; Karelovic, A.

Disclosing the Reaction Mechanism of CO 2 Hydrogenation to Methanol over CuCeO x /TiO 2 : A Combined Kinetic, Spectroscopic, and Isotopic Study

2023. ACS Catalysis, 13 (22), 14699–14715. doi:10.1021/acscatal.3c04243 -

Dorner, I.; Röse, P.; Krewer, U.

Dynamic vs. Stationary Analysis of Electrochemical Carbon Dioxide Reduction: Profound Differences in Local States

2023. ChemElectroChem, 10 (24), Art.-Nr.: e202300387. doi:10.1002/celc.202300387 -

Phan Dang, C.-T.; Tam, N. M.; Huynh, T.-N.; Trung, N. T.

Revisiting conventional noncovalent interactions towards a complete understanding: from tetrel to pnicogen, chalcogen, and halogen bond

2023. RSC Advances, 13 (45), 31507–31517. doi:10.1039/d3ra06078k -

Huber, P.; Pleßow, P. N.

The role of decarboxylation reactions during the initiation of the methanol-to-olefins process

2023. Journal of Catalysis, 428, Art.-Nr.: 115134. doi:10.1016/j.jcat.2023.115134 -

Scholz, B.; Oshchepkov, A. S.; Papaianina, O.; Ruppenstein, C.; Akhmetov, V. A.; Sharapa, D. I.; Amsharov, K. Y.; Pérez-Ojeda, M. E.

An Indacenopicene‐based Buckybowl Catcher for Recognition of Fullerenes

2023. Chemistry – A European Journal, 29 (70), Art.-Nr.: e202302778. doi:10.1002/chem.202302778 -

Ramanathan, E. S.; Chowdhury, C.

Structural and Electronic Properties of Two‐Dimensional Materials: A Machine‐Learning‐Guided Prediction

2023. ChemPhysChem, 24 (21), e202300308. doi:10.1002/cphc.202300308 -

Alrozi, R.; Zubir, N. A.; Bakar, N. F. A.; Ladewig, B. P.; Motuzas, J.; Bakar, N. H. H. A.; Wang, D. K.; da Costa, J. C. D.

Functional role of B-site substitution on the reactivity of CaMFeO